13

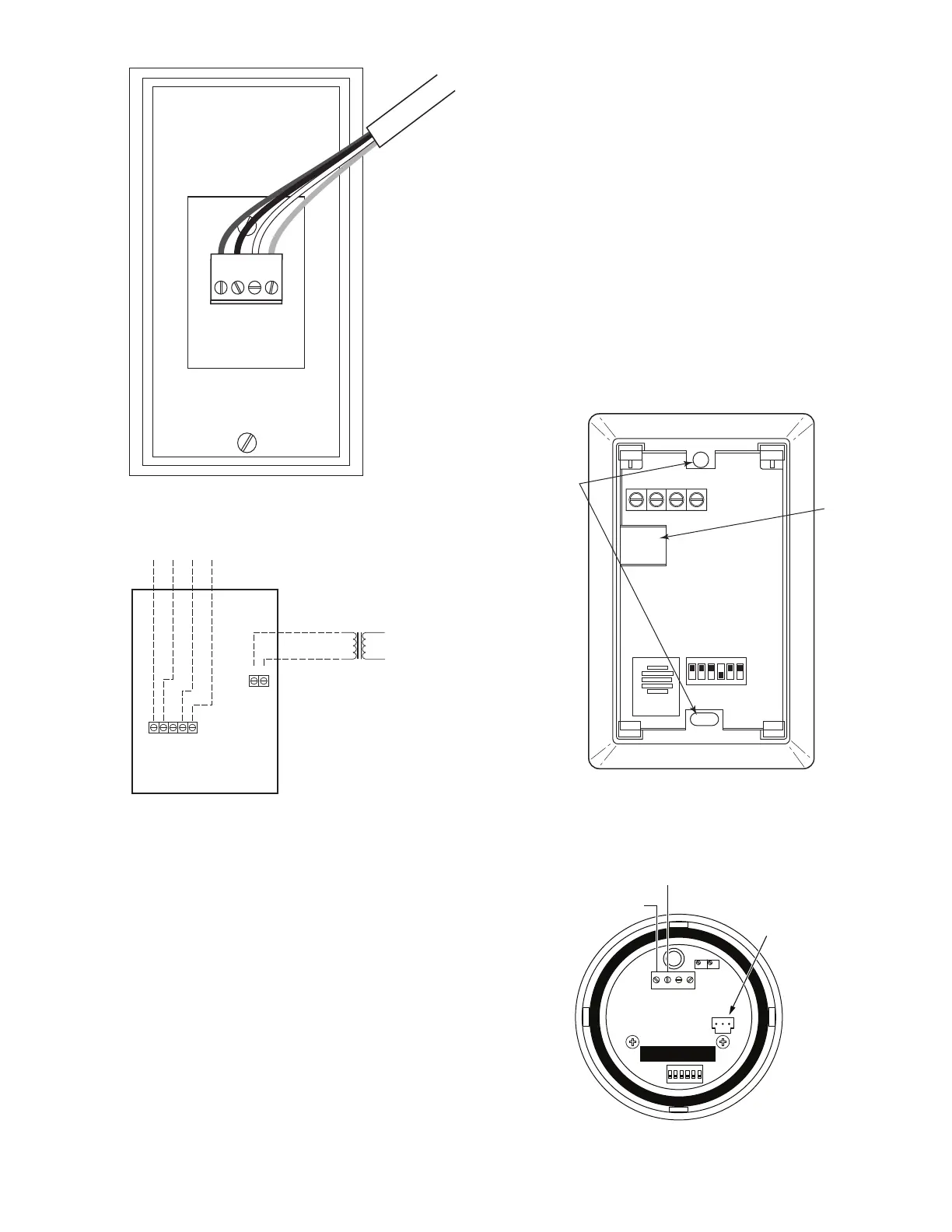

Fig. 11 — Typical Rnet Communication Sensor

Wiring

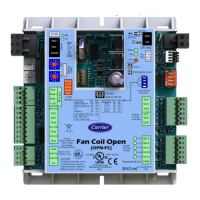

Fig. 12 — Indoor/Outdoor Air Quality (CO

2

) Sensor

(33ZCSPTCO2-01 or 33ZCSPTCO2LCD-01) Typical

Wiring Diagram

RELATIVE HUMIDITY SENSORS (SPACE OR DUCT

MOUNTED)

The accessory space humidity sensor or duct humidity sensor

is used to measure the relative humidity of the air within the

space or return air duct. The RH reading is used to control the

Humidi-MiZer

®

option of the rooftop unit. For wiring distanc-

es up to 500 ft (152m), use a 3-conductor, 18 or 20 AWG

shielded cable. The shield must be removed from the sensor

end of the cable and grounded at the unit end. The current loop

power for the sensor is provided by the RTU Open controller as

24vdc. Refer to the instructions supplied with the RH sensor

for electrical requirements and terminal locations. RTU Open

controller configurations must be changed after adding a RH

sensor. See below and Fig. 13 and 14 for typical non-communi-

cating RH sensor wiring.

• J4-1 or J4-4 = 24vdc loop power

• J4-2 or J4-5 = 4-20mA signal input

NOTE: The factory default for dehumidification control is a nor-

mally open humidistat.

Installing Discrete Inputs

COMPRESSOR SAFETY

The compressor safety input provides the RTU Open controller

with feedback to when the compressor is not running and

should be. This feedback can be provided by a Compressor

Lock-Out (CLO) device or current switch when field installed.

Compressor safety is a dedicated input on the configurable in-

put 3 and tells the RTU Open controller when the compressor

is locked out. The normal condition for compressor safety is

good operation. A normally open compressor safety is the fac-

tory default for all units. Follow specific accessory instructions

if installing a CLO device. The CLO should wire into the unit's

Integrated Staging Control (ISC) board (48/50LC 07-26), Cen-

tral Terminal Board (CTB) (all 48/50TC(Q), 48/50HC(Q),

48/50KC(Q) 04-06 units, and 04-06 48/50LC units) or Unit

Control Board (UCB) (48/50FC(Q) 04-07, 48/50GC(Q)

04-06).

NOTE: Input 3 can also be wired into J-5.

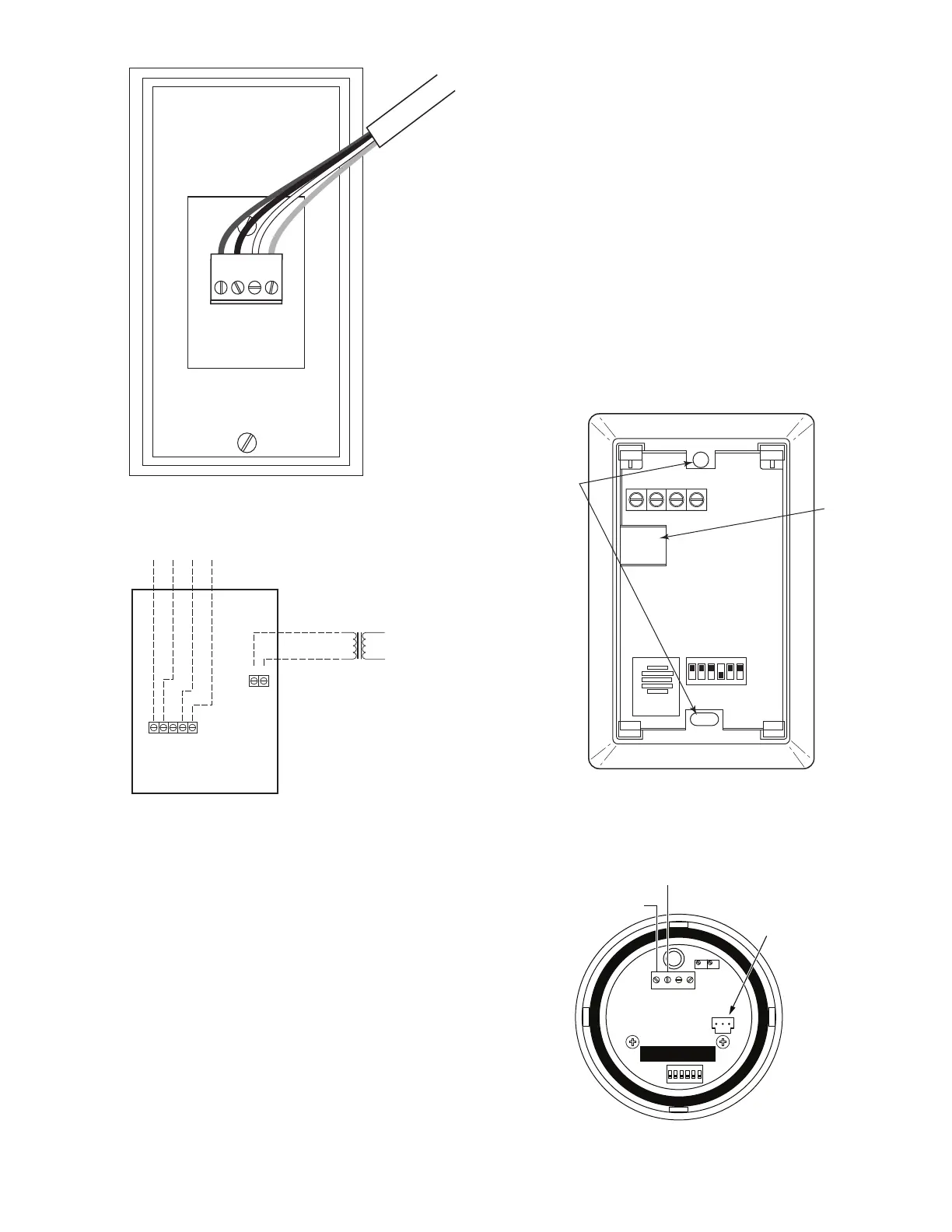

Fig. 13 — Space Relative Humidity Sensor Typical

Wiring

Fig. 14 — Duct Relative Humidity Sensor Typical

Wiring

To controller

24 Vac Line

Dedicated Transformer

+

-

24 Vac

or Vdc

8 7 6 5 4

2 1

SENSOR LEGEND

1 +24 Vac/Vdc

2 Gnd (-24 Vac/Vdc)

4 -Thermistor

5 +Thermistor

6 4-20 mA

7 SIG COM

8 0-5 Vdc

Io Vin Gnd Vo

SW2

123456

ON

MOUNTING

HOLES

WIRING

OPENING

Vin – J4-1 or J4-4 24Vdc

Io

– J4-2 or J4-5 -20mA output

SPAN

ZERO

4-20

mA

VAC

or

VDC

GND 0-5V

or

0-10V

123456

ON

RELATIVE HUMIDITY SENSOR

(POLARIZED MALE

CONNECTOR)

J4-1 OR J4-4 + 24 VDC SUPPLY VOLTAGE

J4-2 OR J4-5 (-) 4 TO 20 mA

CURRENT LOOP OUTPUT

TO RTU OPEN

Loading...

Loading...