17

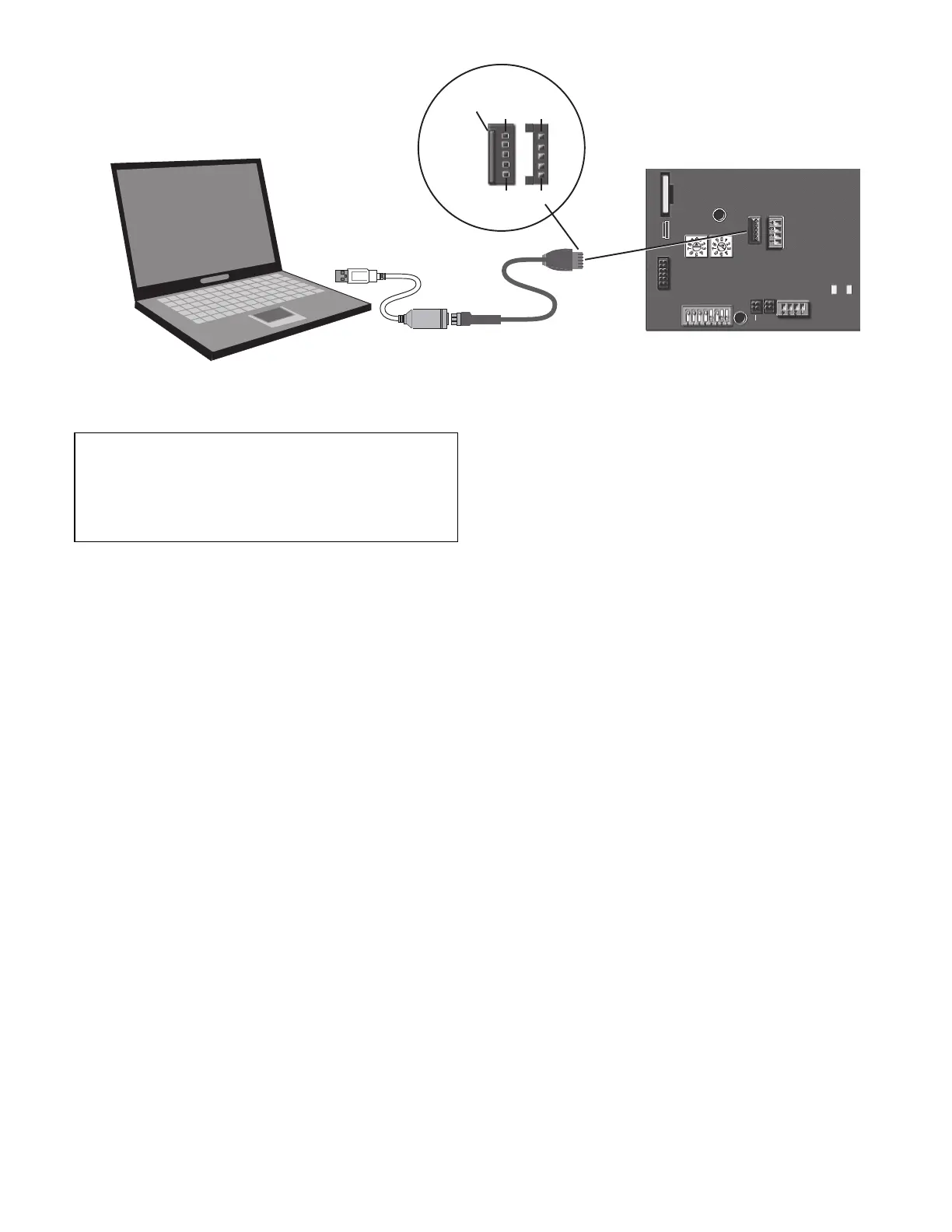

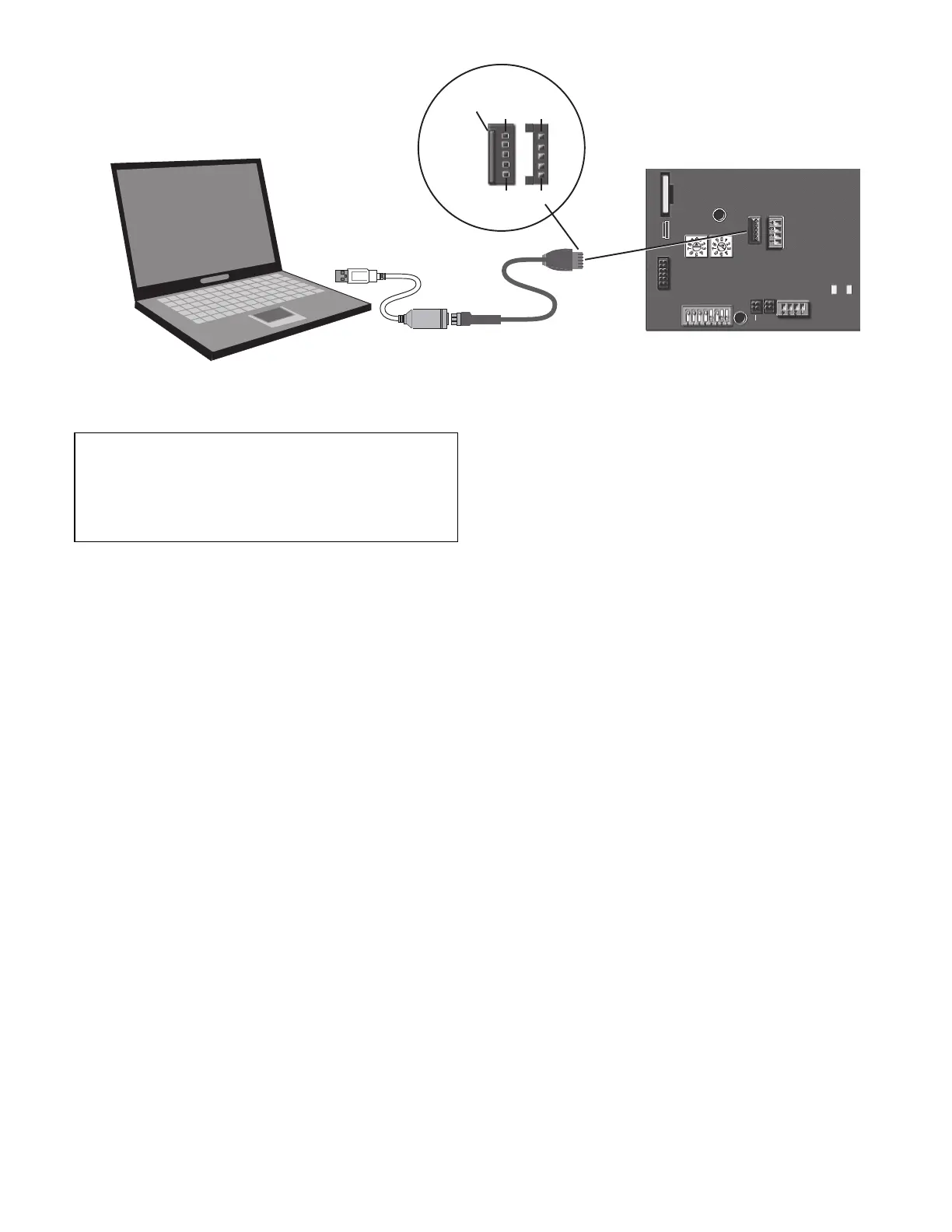

Fig. 20 — PC Running Field Assistant

START-UP

Besides the base unit start-up, there are a few steps to take to

properly start-up the controls. The RTU Open Service Test

function should be used to assist in the base unit start-up and

also allows verification of output operation. Controller config-

uration is also part of start-up. This is especially important

when field accessories have been added to the unit. The factory

pre-configures options installed at the factory. There may also

be additional installation steps or inspection required during

the start-up process.

EcoBlue™ Fan Set Up

The RTU Open controller controls the vane axial fan directly,

therefore the UCB fan set up is not needed. The maximum,

minimum, and heat speed setting can be adjusted to restrict too

much or prevent to too less of air flow. However the control

will speed up the fan as needed during heating or cooling so the

maximum should be the only one needed for duct restrictions.

Additional Installation/Inspection

Inspect the field installed accessories for proper installation,

making note of which ones do or do not require configuration

changes. Inspect the RTU Open Alarms for initial insight to

any potential issues. See troubleshooting section for alarms. In-

spect the SAT sensor for relocation as intended during installa-

tion. Inspect special wiring as directed below.

POWER EXHAUST RELAY POWER

The relay used by the RTU Open board to control power ex-

haust is a dry contact which means it does not have 24vac. This

24vac must be connected to the relay to allow it operate the

power exhaust relay in the PE accessory. A 24vac source

should be provided to the J11-2 pin on the RTU Open control-

ler. This can be provided by the unit's transformer from various

sources.

NOTE: The Factory-installed power exhaust comes pre-con-

figured and does not require routing 24vac as described above.

This factory-installed option is only available on the following

vertical air flow units: 48/50TC(Q) 17-30, 48/50HC 16-30, and

48/50LC 14-26.

SERVICE TEST

The Service Test function can be used to verify proper opera-

tion of compressors, heating stages, indoor fan, power exhaust

fans, economizer, and dehumidification. Use of Service Test is

recommended at initial system start up and during trouble-

shooting. See Appendix A for Service Test Mode table.

Service Test mode has the following changes from normal op-

eration:

• Outdoor air temperature limits for cooling circuits, econo-

mizer, and heating are ignored.

• Normal compressor time guards and other staging delays

are ignored.

• The status of Alarms (except Fire and Safety chain) is ig-

nored, but all alerts and alarms are still broadcast on the

network.

Service Test can be turned ON/OFF from Field Assistant, from

the network, or from the Equipment or System Touch. Once

turned ON, other entries may be made with the display or

through the network. To turn Service Test on, change the value

of Test Mode to ON, to turn Service Test off, change the value

of Test Mode to OFF.

Service Test allows testing of each controller output.

Binary Service Test functions are on when the Default Value is

set to Enable and off when set to Disable.

The output of the Analog Service Test is controlled by percent-

age (0-100%) entered into the Default Value.

It is recommended to return every Service Test variable to Disable

or 0.00 after testing each function (unless that test variable must be

active to test a subsequent function. As in Compressor 2 Test).

All outputs return to normal when Service Test is set to Disable.

FAN TEST

This point allows the board's fan output to be manually turned

On (Enable) and Off (Disable). Other test points that require

the fan for operation will automatically turn the fan on and this

point will still show “Disable.” Fan test can operate simultane-

ously with other Service Test Points. For units equipped with

variable speed fans, the fan test will operate the unit's fan at

minimum VFD output speed.

HIGH SPEED FAN TEST

Use the High Speed Fan Test to activate and deactivate the

Supply Fan (BO-1) output. Note that this output is only appli-

cable if Fan Control is set to Two Speed and Unit Type is NOT

equal to HP O/B Ctrl.

Connect to

computer’s

USB port

Connect to

the Local

Access port

USB Link Kit

RTU Open Controller

Access

Port

J12

P1 P1

P5 P5

LOCAL

ACCESS

PORT

GND

GND

*Therm

mA

*Therm

mA

UI-10

UI-11

SW3

on

COMM

OPTION

CR2032

+

-

SW1 SW2

MSB LSB

TXRX

+12 DVC

Rnet-

Rnet+

GND

RNET

J12

J13

J15

J20

IMPORTANT: Follow the base unit's start-up sequence doc-

umented in its specific instructions. Use the base unit's start-

up check list when performing the start-up. At the end of

this manual there is an additional RTU Open controller

Start-Up Sheet to be completed and included with the base

unit check list.

Loading...

Loading...