15

FILTER STATUS

The filter status accessory is a field-installed accessory. This

accessory detects plugged filters. When installing this accesso-

ry, the unit must have a free input (input 3, 5, 8, or 9). One of

the dedicated functions (Humidistat, Fire shutdown, Enthalpy,

or Compressor safety) must not be in use to configure Filter

Status. Refer to the configuration section for details on config-

uring inputs for specific functions and state. Refer to Fig. 1 for

wire terminations at J5.

FAN STATUS

The fan status accessory is a field-installed accessory. This ac-

cessory detects when the indoor fan is moving air. When in-

stalling this accessory, the unit must have a free input (input 3,

5, 8, or 9). One of the dedicated functions (Humidistat, Fire

shutdown, Enthalpy, or Compressor safety) must not be in use

to configure Fan Status. Refer to the configuration section for

details on configuring inputs for specific functions and state.

Refer to Fig. 1 for wire terminations at J5.

REMOTE OCCUPANCY

The remote occupancy accessory is a field-installed accessory.

This accessory provides an input to change the units occupancy

status. When installing this accessory, the unit must have a free

input (input 3, 5, 8, or 9). One of the dedicated functions (Hu-

midistat, Fire shutdown, Enthalpy, or Compressor safety) must

not be in use to configure remote occupancy. Refer to the con-

figuration section for details on configuring inputs for specific

functions and state. Refer to Fig. 1 for wire terminations at J5.

IGC OVERRIDE

The IGC Override input is factory-installed for 48LC 07-26

gas heat units. This input provides an indication that the gas

valve is stuck open and the heat is still operating after any call

for heating has been dropped. This function requires the use of

input 9. Any of the other dedicated functions (Humidistat, Fan

Status, Filter Status, Remote Occupancy, or Door Contact) will

not be in use if IGC Override is configured. Refer to the con-

figuration section for details on configuring inputs for specific

functions and state. Refer to Fig. 5 for wire terminations.

Communication Wiring-Protocols

GENERAL

Protocols are the communication languages spoken by control

devices. The main purpose of a protocol is to communicate in-

formation in the most efficient method possible. Different pro-

tocols exist to provide different kinds of information for differ-

ent applications. In the BAS application, many different proto-

cols are used, depending on manufacturer. Protocols do not

change the function of a controller; just make the front end user

different.

The RTU Open controller can be set to communicate on four

different protocols: BACnet, Modbus, N2, and LonWorks.

Switch 3 (SW3) on the board is used to set protocol and baud

rate. Switches 1 and 2 (SW1 and SW2) are used to set the

board's network address. See Fig. 16 and 17 for protocol switch

settings and address switches. The third party connection to the

RTU Open controller is through plug J19. See Fig. 18 for

wiring. Refer to the RTU Open v3 Integration Guide for more

detailed information on protocols, third party wiring, and

networking.

NOTE: Power must be cycled after changing the SW1-3 switch

settings.

i-Vu BUILDING AUTOMATION SYSTEM

i-Vu

®

is a Carrier front-end and Building Automation System

(BAS). It is a web based network system that uses a native

BACnet over MS/TP communication protocol. The speed of

the network can range from 9600 to 76,800 baud. Open con-

trollers communicate with a proprietary language called Link-

age in i-Vu. Linkage is established automatically and allows

the flow of specific data across Open devices. Refer to i-Vu lit-

erature for more information on i-Vu.

BACnet MS/TP

BACnet Master Slave/Token Passing (MS/TP) is used for com-

municating BACnet over a sub-network of BACnet-only con-

trollers. This is the default Carrier communications protocol.

Each RTU Open module acts as an MS/TP Master. The speed

of an MS/TP network can range from 9600 to 76.8K baud.

Physical Addresses can be set from 01 to 99.

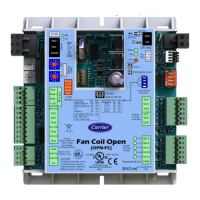

Fig. 16 — RTU Open Controller SW3 Dip Switch Settings

SW3 Protocol Selection

PROTOCOL DS8 DS7 DS6 DS5 DS4 DS3 DS2 DS1

BACnet MS/TP (Master) Unused OFF OFF OFF ON OFF Select Baud Select Baud

Modbus (Slave) Unused OFF OFF ON ON OFF Select Baud Select Baud

N2 (Slave) Unused OFF OFF OFF ON ON OFF OFF

LonWorks Unused ON ON OFF ON OFF OFF ON

NOTE:

DS = Dip Switch

BACnet MS/TP SW3 example shown

Baud Rate Selections

BAUD RATE DS2 DS1

9,600 OFF OFF

19,200 ON OFF

38,400 OFF ON

76,800 ON ON

UNUSED

(OFF)

(ON)

COMM

OPTION

PORT

SET TO MSTP

(MASTER)

SET TO

38.4k

BAUD

PROTOCOL SELECTOR DIP SWITCHES

Loading...

Loading...