Installation and maintenance instructions

EN

3.1.b Drain pipe connection

• Insert the drain hose into the drain sump.

IMPORTANT

Provide a oor drain with a drain trap and connect the machine to the drain using the hose supplied, so that it

is sloping towards the drain.

Also make sure that there are no bottlenecks along it.

Make sure that the wall-mounted drain hose can withstand a temperature of 70°C.

For machines with steam heating, the drain must have an adequate slope towards the recovery system or a

recirculation pump that ensures independent removal of condensate.

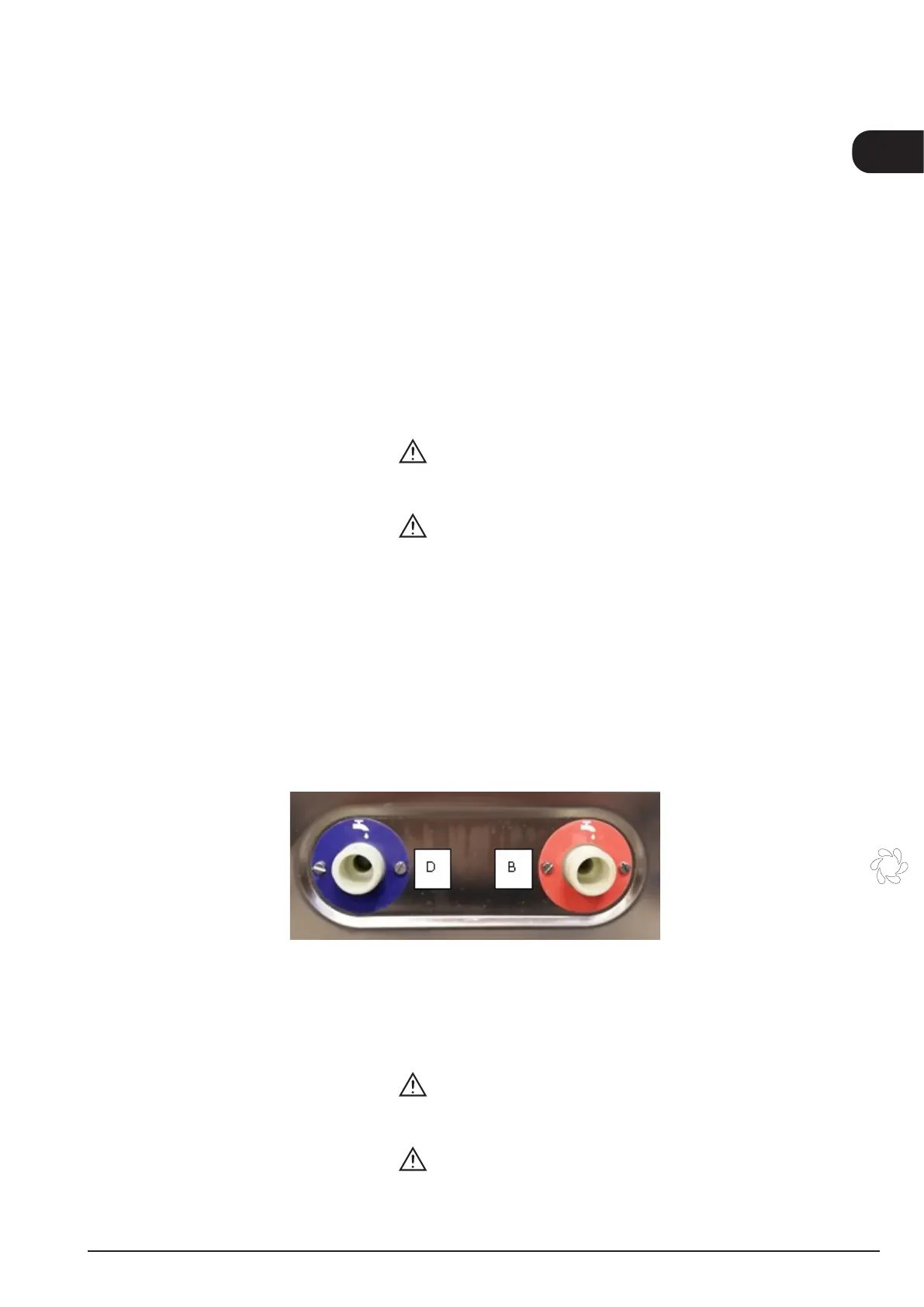

3.1.c Hot water hydraulic connection (“B” RED - if present)

Supplying of the machine with drinking water is a fundamental requirement.

Provide for a 3/4” G threaded valve to which to screw the end of the inlet hose, placing the lter “B” in between.

For the sizing of the same, refer to the installation drawing.

ATTENTION

It is mandatory to replace the seals of the ller hose for water supply, whenever it is disassembled and

reassembled.

ATTENTION

Wherever sand is found in the water supply circuit, a lter must be applied between the water circuit and the

machine.

The operating pressure must not be less than 2 bar and more than 4 bar (200-400 kPa).

If the pressure is lower, it is recommended to install a pressure booster pump. If the pressure is higher, it is

recommended to install a pressure reducer.

For a good result it is advisable to have the inlet water with a hardness not exceeding 10°F and a temperature

of 55°C with a tolerance of 0+10°C.

For greater hardness, use machines with a built-in softener, ion exchange or reverse osmosis softeners.

For appliances connected to the water mains by removable hose sets, a new set of hoses must be used and

the old ones must not be reused.

The optimal quantity of water for rinsing is guaranteed by the ow limiter of the solenoid valve Y10.

3.1.d Cold water hydraulic connection (“D” BLUE - if present)

Supplying of the machine with drinking water is a fundamental requirement.

Provide for a 3/4” G threaded valve to which to screw the end of the inlet hose, placing the lter “D” in between.

For the sizing of the same, refer to the installation drawing.

ATTENTION

It is mandatory to connect the cold water supply hose to a cut-off valve in order to separate the supply system

from the machine itself and to check that there are no bottlenecks.

ATTENTION

It is mandatory to replace the seals of the ller hose for water supply, whenever it is disassembled and

reassembled.

33

Loading...

Loading...