Installation and maintenance instructions

EN

2.1 INSTALLATION

During installation, carry-out a good machine levelling, which is a prerequisite for a correct operation thereof.

In order to prevent any damages caused by vapours going out of the machine, make sure that the surrounding

materials don’t deteriorate in their presence.

2.1.a Electrical connection

The electrical power supply shall be fed to the machine by connecting it to a wall-mounted differential magneto-

thermal on/off switch, with a contact aperture distance equal to or greater than 3 mm.

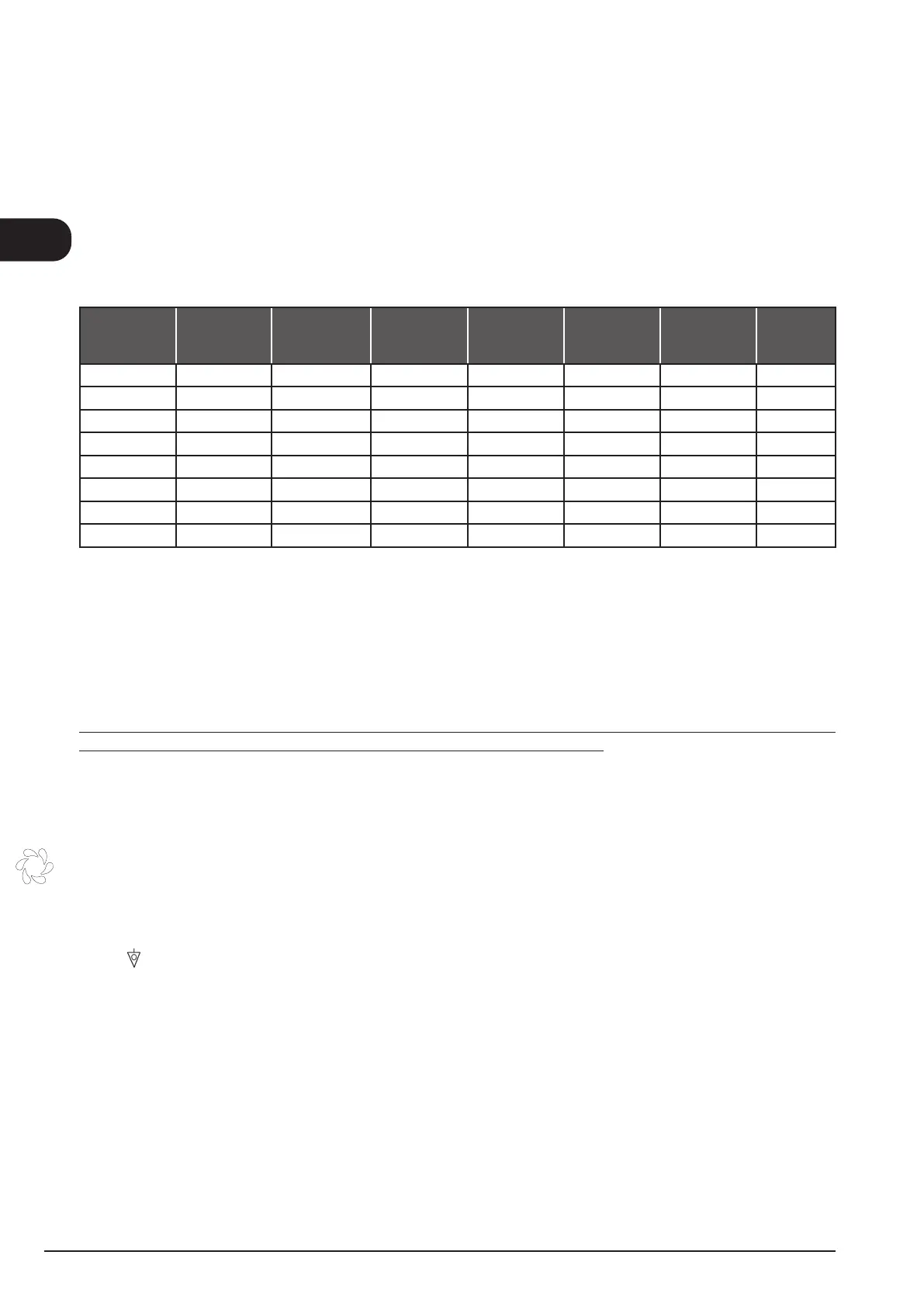

The said magnetothermal on/off switch should be rated according to the following table, as a function of the

power supply voltage, the machine model, and the heating type (electrical or steam heating).

Model

Heating type

Power supply

(V)

Electrical

loading

(kW)

Electrical

absorption

(A)

Feeding cable

(mm²)

Wall switch

(A)

Switch

curve

GE605

Electric

230V/3

12 31,5 6 40,0 C

GE605

Electric

400V/3N

12 18,3 4 25,0

C

GE605+CRC

Electric

400V/3N

12 18,3 4 25,0

C

GE755

Electric

230V/3

12

31,5 6 40,0 C

GE805

Electric

230V/3

12 31,5 6 40,0 C

GE805

Electric

400V/3N

12 18,3 4 25,0

C

GE1005

Electric

230V/3

15 37,7 10 40,0 C

GE1005

Electric

400V/3N

15 23,0 6 32,0

C

* Cold water connection

N.B.: Check that the voltage which the machine is set to correspond to the power supply voltage available.

Power cable cross section must not be less then that indicated in the table. If the cables are not protected by a

sheathing, use a flexible, protected cable in Polychloroprene with equivalent H07RN-F characteristics.

Cable must be connected to X1 terminal block passing through the cable brake (see refer to electrical diagram).

Check the line length; should it be too long, conform the line cross section to such line length and to current

drain. The power cable must not be pulled or pinched during normal operation or routine maintenance.

If the power cable is damaged, it must be replaced by the manufacturer or its technical assistance service or in

any case by a person with a similar qualification, in order to prevent any risk.

If the cable needs to be replaced, use only type H07RN-F.

The electrical safety of this equipment is only assured if it is connected as follows

It is necessary to connect the equipment to an effective ground installation, as specified by the electrical safety

regulations in force.

Check that this basic requirement is complied with and, in case of doubt, ask for a careful check of the installation

by a qualified personal.

In addition, the equipment shall be part of an equipotential system, the effectiveness of which should be checked

according to the regulations in force.

The connection should be made at the screw marked by the respective label located on the equipment back

side. (

)

The manufacturer declines any responsibility for any damages caused by lack of an effective ground installation.

42

Loading...

Loading...