Installation and maintenance instructions

EN

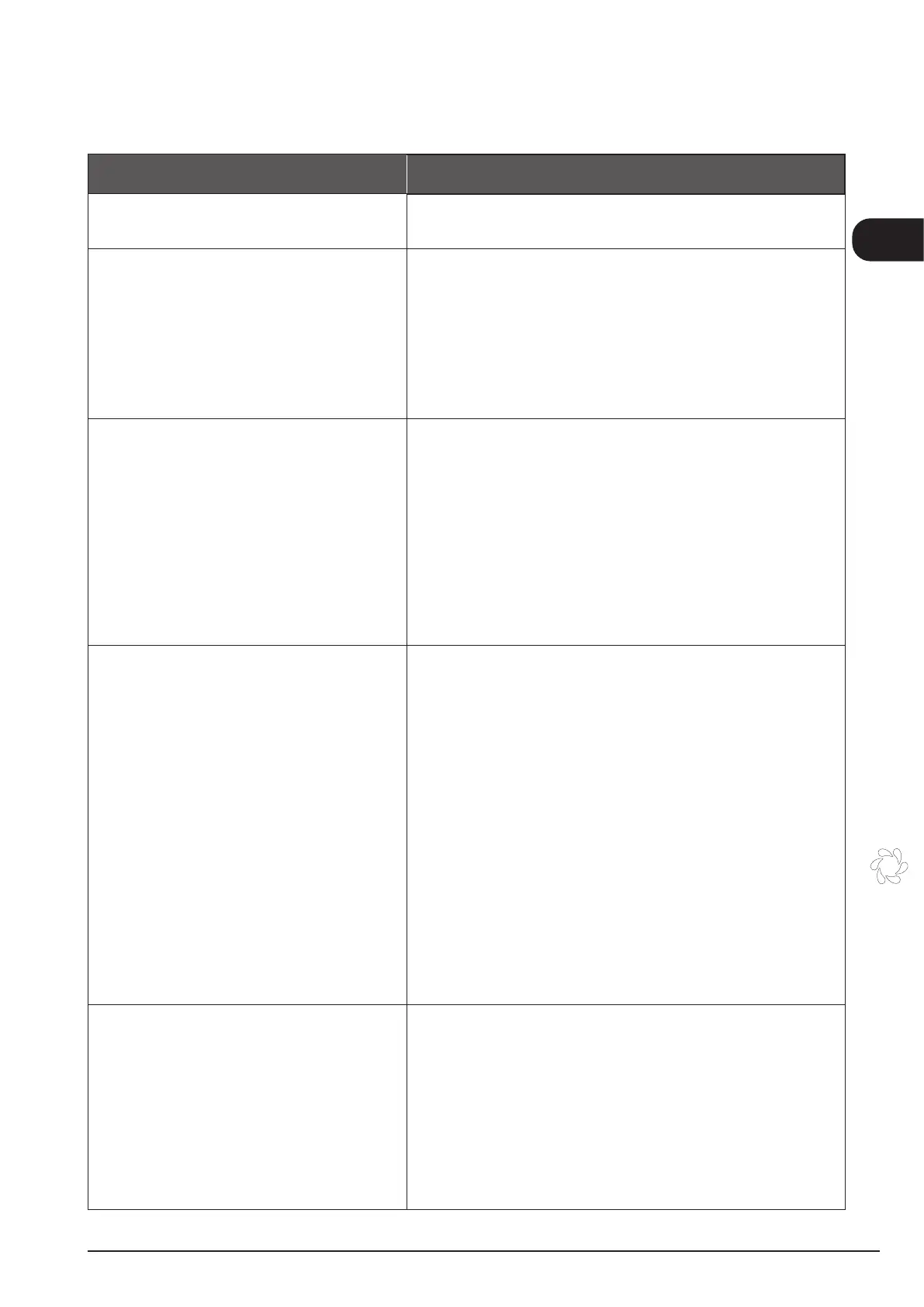

2.2 TROUBLESHOOTING

A list of drawbacks possibly occurring with the use of the pot-washing machine, their causes and possible

remedies:

DRAWBACK POSSIBLE CAUSES AND REMEDIES

The display indicates “OFF”

A) Check that the wall-mounting switch is ON and the respective

fuses are not burnt

The tank does not ll up

A) Check that pressure switch S2 is not calibrated or out of

service

B) Check that the feeding water intercept valve is open and

water is present in the piping system.

C) Check that the overflow is in the respective position.

D) Check that the coil of the solenoid valve is not broken and

that voltage is fed there to.

The tank does not stop being lled upon

reaching the desired level

A) Check that the trap of the pressureswitch has no porosities

and the connection pipe is not disconnected.

B) Check that the pressure switch is in good conditions and is

not calibrated.

C) Check that there is no dirty in the solenoid valve. This

drawback can be noted because the machine continues to

load water, whilst the main on/off switch is off.

D) In case of the machine remains full of tank water for many

hours (overnight) the machine will continue to fill. Thus drain

completely the tank and then re-fill.

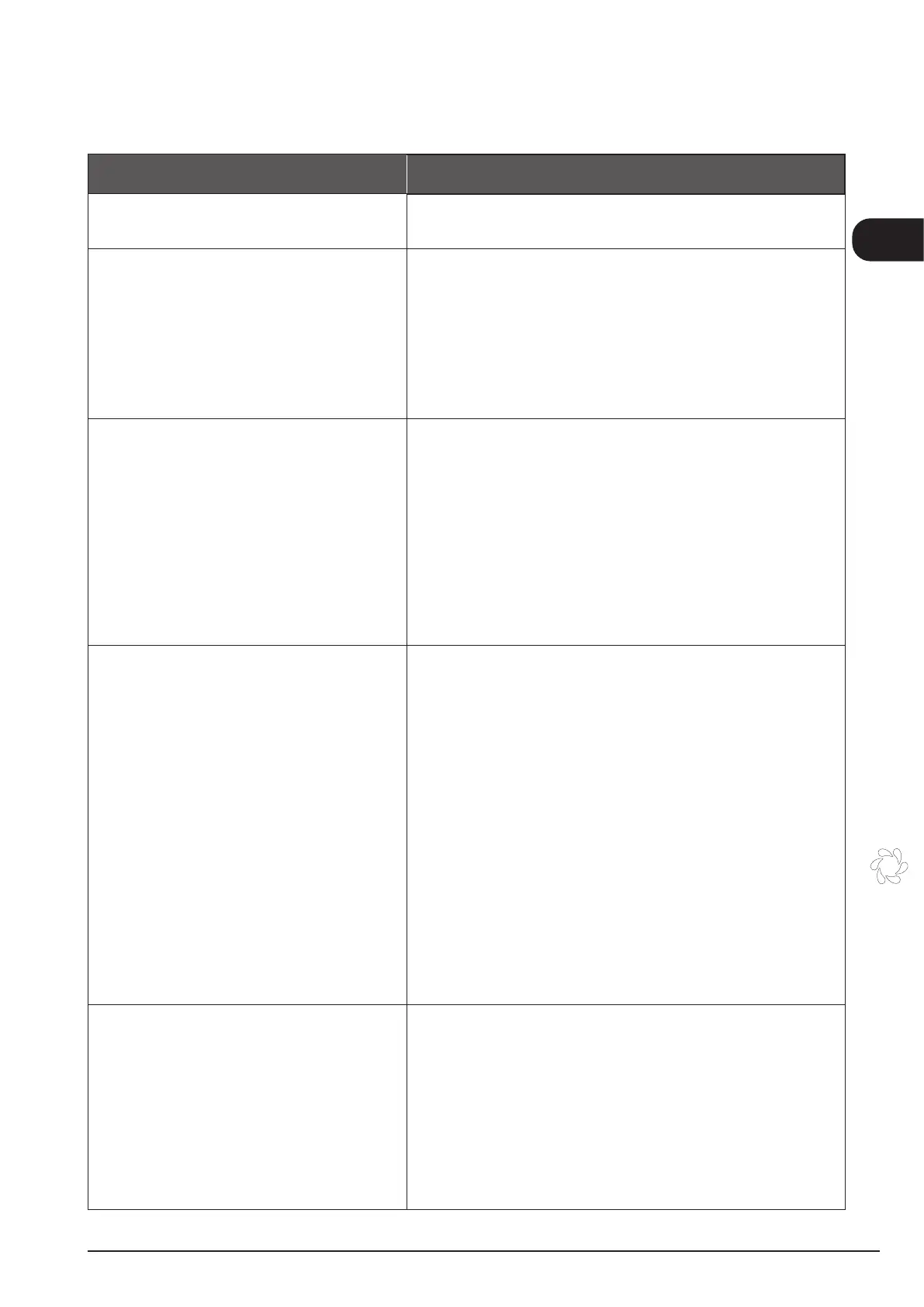

Insufcient washing

A) Check that the detergent is effective, is of the type

recommended for industrial pot-washing machines, and it

is proportioned for the right concentration.

B) Check that the detergent container is not empty and

operates correctly.

C) Check that the jets of the washing swivels are not clogged.

If necessary, clean them.

D) Check that the tank temperature is the specified one.

E) One or several pumps don’t operate, in this case check

that:

the overload cut-out did not switch the pump in question

and, if necessary, restore it

the fuses or the coil of the respective remote switch are not

broken

the pump is not blocked or rotates in the reverse direction.

Tank temperature insufcient

(alarm “H. .3.”)

A) Check that the thermostat is not faulty or not calibrated.

B) Check that the temperature of the feeding water is in the

range from 50° -0/+10°C, as specified.

C) Check that the temperature is set to the 50°C-0+10°C

D) Check that the fuses and the coil of the remote switch

relevant to the tank resistor are not broken (this applies to

electric heating machines only).

E) Check that the heater element is effective.

47

Loading...

Loading...