Safety

Guard Function and Features

The guard is a very important safety feature,

designed to reduce the risk of injury associ-

ated with blade contact. Install the guard

correctly. Follow the specific instructions

in the ripping and crosscutting sections to

set and use the guard correctly for each

type of cuL

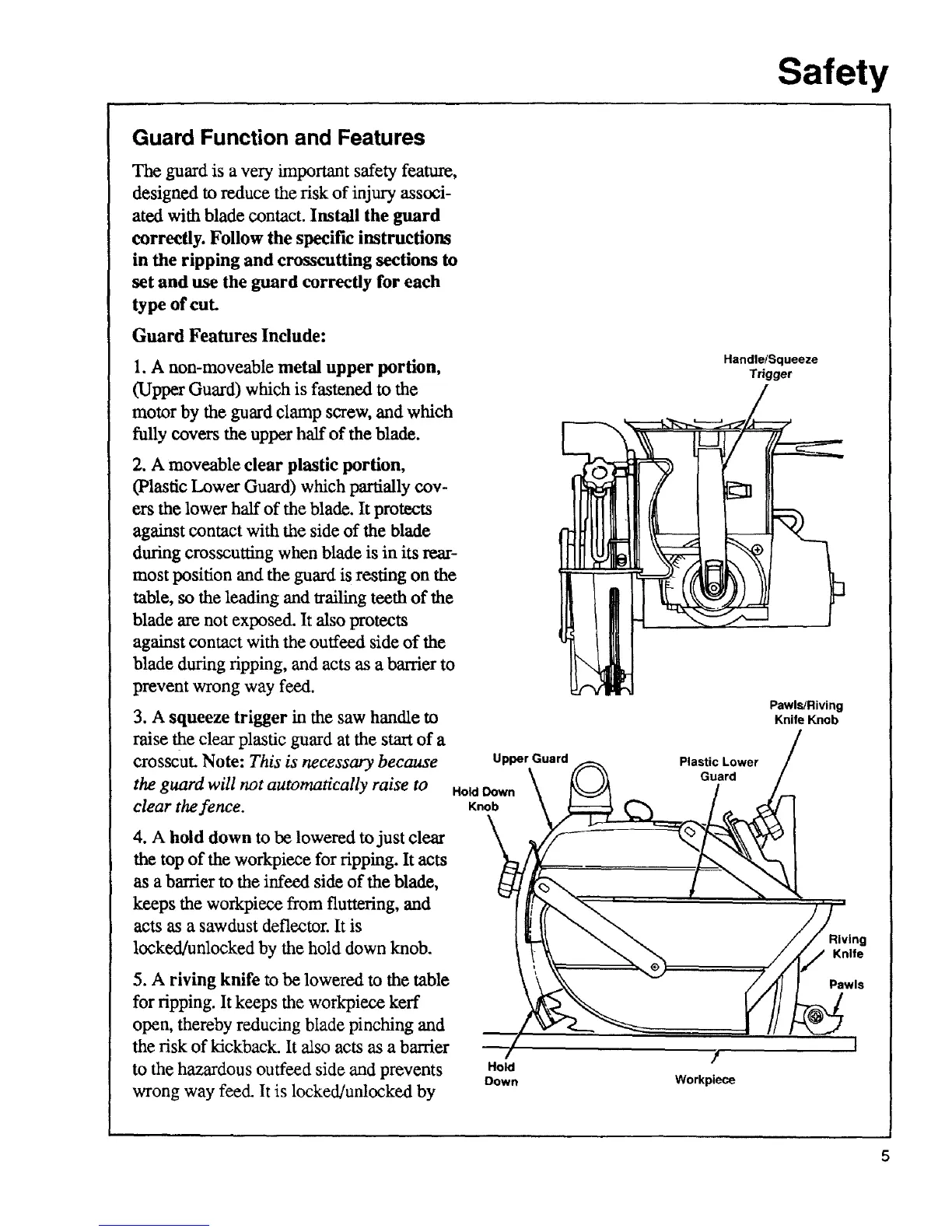

Guard Features Include:

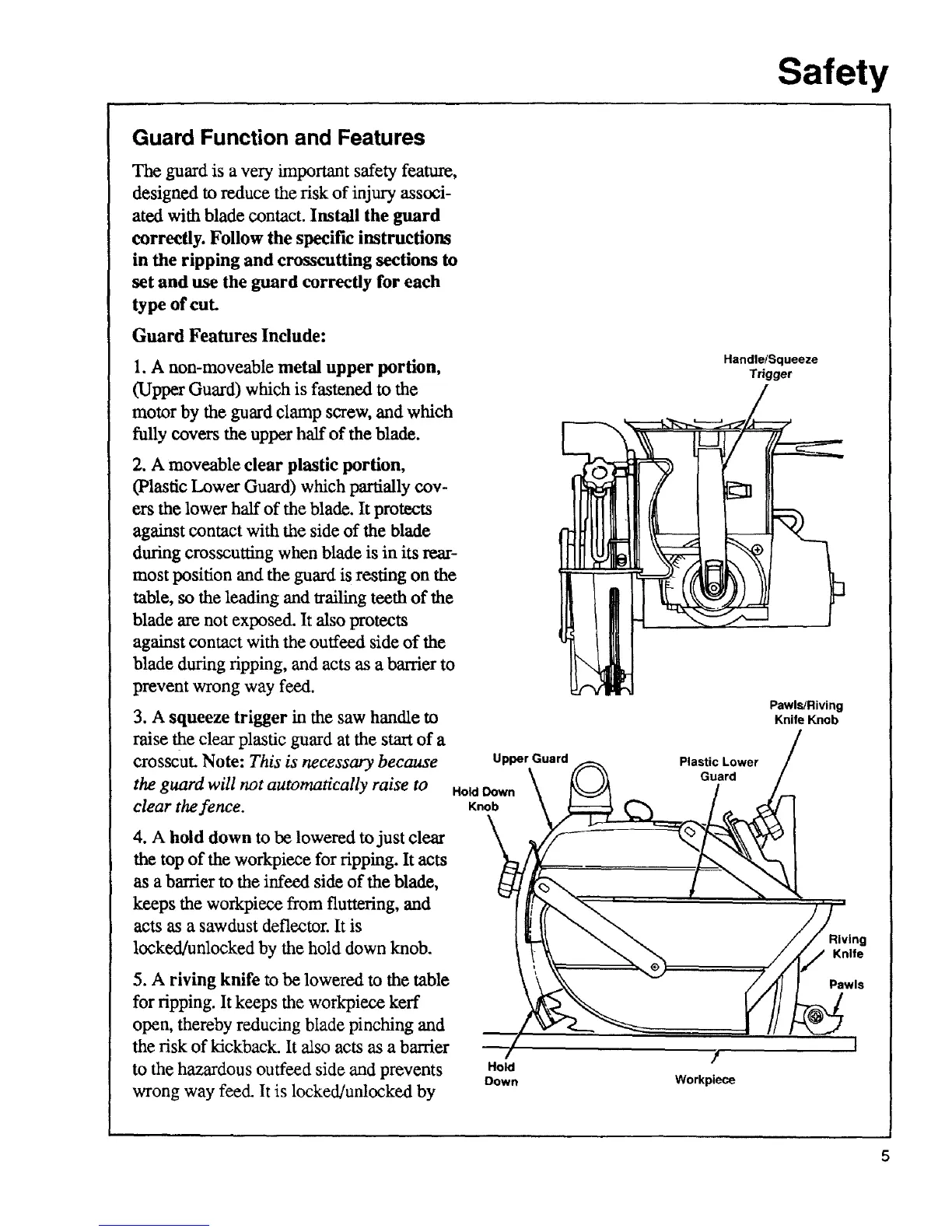

1. A non-moveable metal upper portion,

(Upper Guard) which is fastened to the

motor by the guard clamp screw, and which

fully covers the upper half of the blade.

2. A moveable clear plastic portion,

(Plastic Lower Guard) which partially cov-

ers the lower half of the blade. It protects

against contact with the side of the blade

during crosscutting when blade is in its rear-

most position and the guard is resting on the

table, so the leading and trailing teeth of the

blade are not exposed. It also protects

against contact with the ouffeed side of the

blade during ripping, and acts as a barrier to

prevem wrong way feed.

3. A squeeze trigger in the saw handle to

raise the clear plastic guard at the start of a

crosscut. Note: This is necessary because

the guard will not automatically raise to

clear the fence.

4. A hold down to be lowered to just clear

the top of the workpiece for ripping. It acts

as a barrier to the infeed side of the blade,

keeps the workpiece from fluttering, and

acts as a sawdust deflector. It is

locked/unlocked by the hold down knob.

5. A riving knife to be lowered to the table

for ripping. It keeps the workpiece kerf

open, thereby reducing blade pinching and

the risk of kickback. It also acts as a barrier

to the hazardous outfeed side and prevents

wrong way feed. It is locked/unlocked by

Upper Guard

Hold Down

Knob

Hold

Down

Handle/Squeeze

Trigger

Pawls/Riving

Knife Knob

Plastic Lower

Guard

Riving

Knife

Pawls

!

Workpiece

Loading...

Loading...