(b) If column moves front to rear within the

column support, tighten the four (4) bolts,

with a 9/16 socket and extension, located

through holes in rear column support cover

until movement disappears. Elevation should

be smooth and firm. Recheck adjustments,

repeat steps (a) and (b) if necessary.

2. Locate the four (4) plastic hole caps in loose

parts bag #661. After all adjustments are made to

the column support insert the plastic caps in all

four holes in rear column support cover.

STEP TWO

NOTE: The following adjustment, performed proper-

ly, will result in the work table being parallel to the

arm. This helps insure the blade will cut the same

depth along the entire crosscut travel.

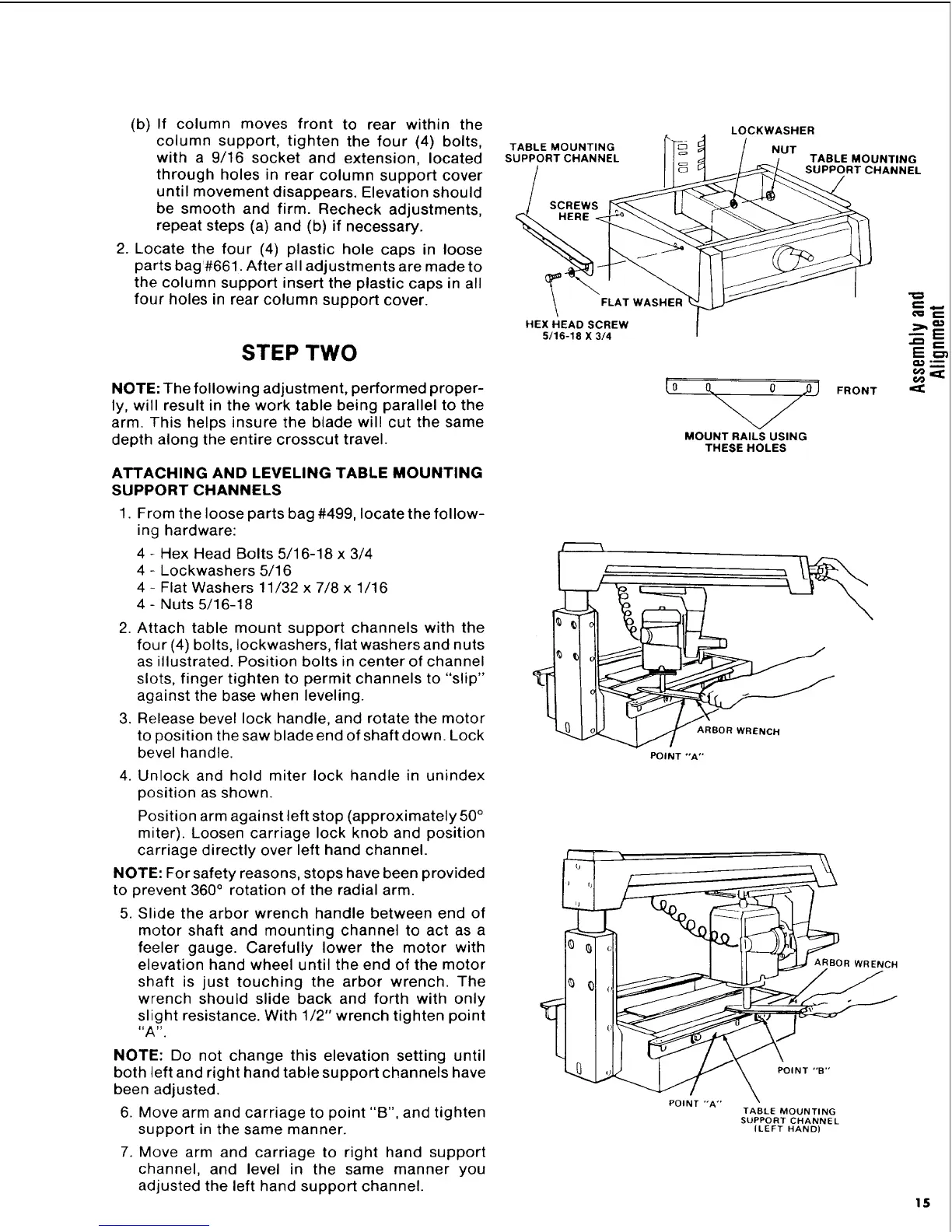

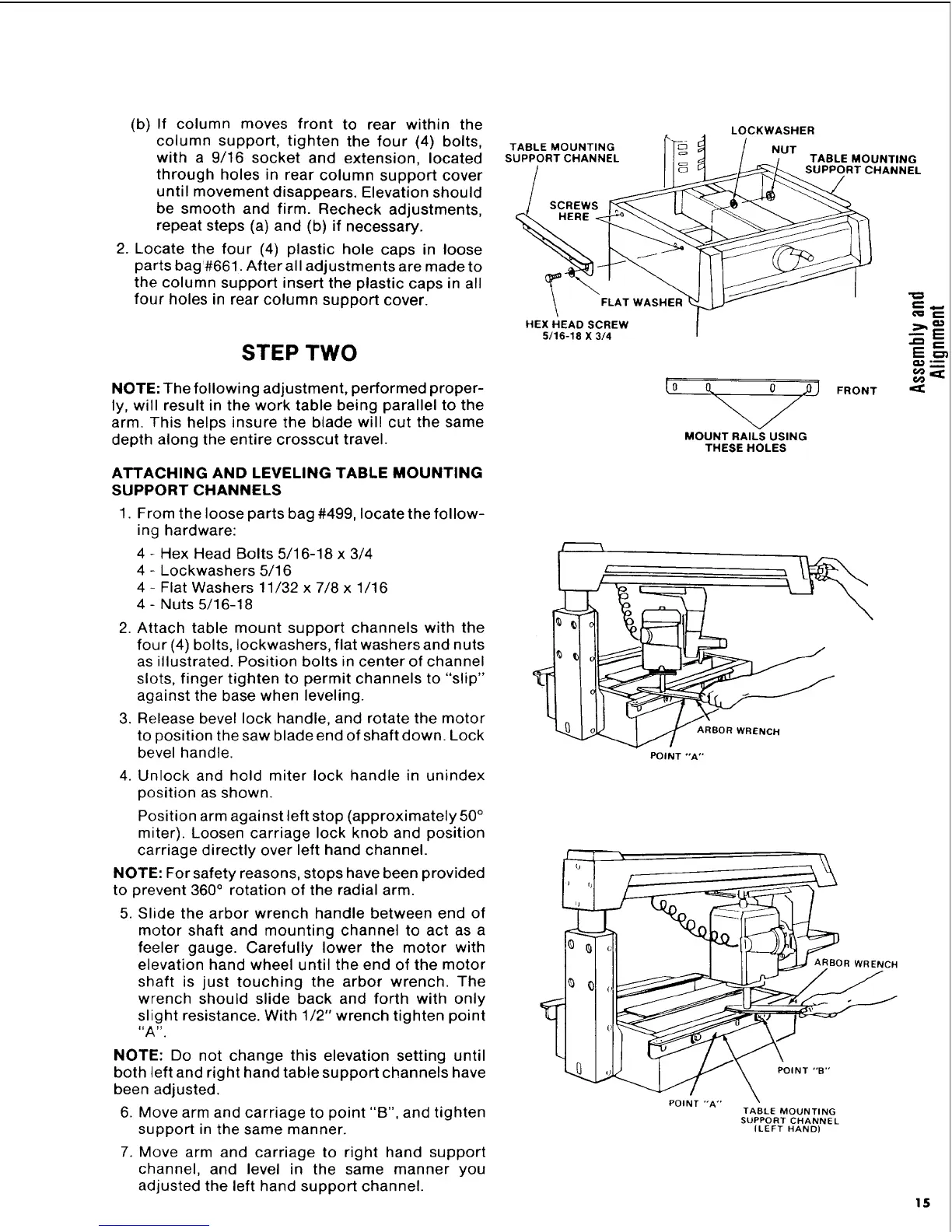

ATTACHING AND LEVELING TABLE MOUNTING

SUPPORT CHANNELS

1. From the loose parts bag #499, locate the follow-

ing hardware:

4 - Hex Head Bolts 5/16-18 x 3/4

4 - Lockwashers 5/16

4 - Flat Washers 11/32 x 7/8 x 1/16

4 - Nuts 5/16-18

2. Attach table mount support channels with the

four (4) bolts, Iockwashers, flat washers and nuts

as illustrated. Position bolts in center of channel

slots, finger tighten to permit channels to "slip"

against the base when leveling.

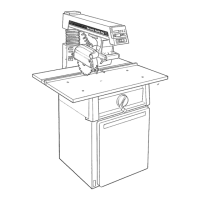

3. Release bevel lock handle, and rotate the motor

to position the saw blade end of shaft down. Lock

bevel handle.

4. Unlock and hold miter lock handle in unindex

position as shown.

Position arm against left stop (approximately 50°

miter). Loosen carriage lock knob and position

carriage directly over left hand channel.

NOTE: For safety reasons, stops have been provided

to prevent 360 ° rotation of the radial arm.

5. Slide the arbor wrench handle between end of

motor shaft and mounting channel to act as a

feeler gauge. Carefully lower the motor with

elevation hand wheel until the end of the motor

shaft is just touching the arbor wrench. The

wrench should slide back and forth with only

slight resistance. With 1/2" wrench tighten point

I'Al_"

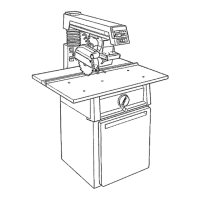

NOTE: Do not change this elevation setting until

both left and right hand table support channels have

been adjusted.

6. Move arm and carriage to point "B", and tighten

support in the same manner.

7. Move arm and carriage to right hand support

channel, and level in the same manner you

adjusted the left hand support channel.

TABLE MOUNTING

SUPPORT CHANNEL

LOCKWASHER

NUT

TABLE MOUNTING

SUPPORT CHANNEL

SCREWS

HERE

FLAT WASHER

HEX HEAD SCREW

5/16-18 X 3/4

MOUNT RAILS USING

THESE HOLES

FRONT

ARBOR WRENCH

POINT"A"

POINT "'A"

ARBOR WRENCH

POINT "B'"

TABLE MOUNTING

SUPPORT CHANNEL

ILEFT HAND)

E==

15

Loading...

Loading...