A light film of oil should be wiped on the face of the

column tube to lubricate the fit between the column

tube and column support.

The thread on the elevation shaft assembly can be

lubricated through the oil hole in the center of the

radial arm cap. Lubricate ramp on the swivel index

spring.

CAUTION: Excessive oil at any location will attract

airborne dust particles and sawdust.

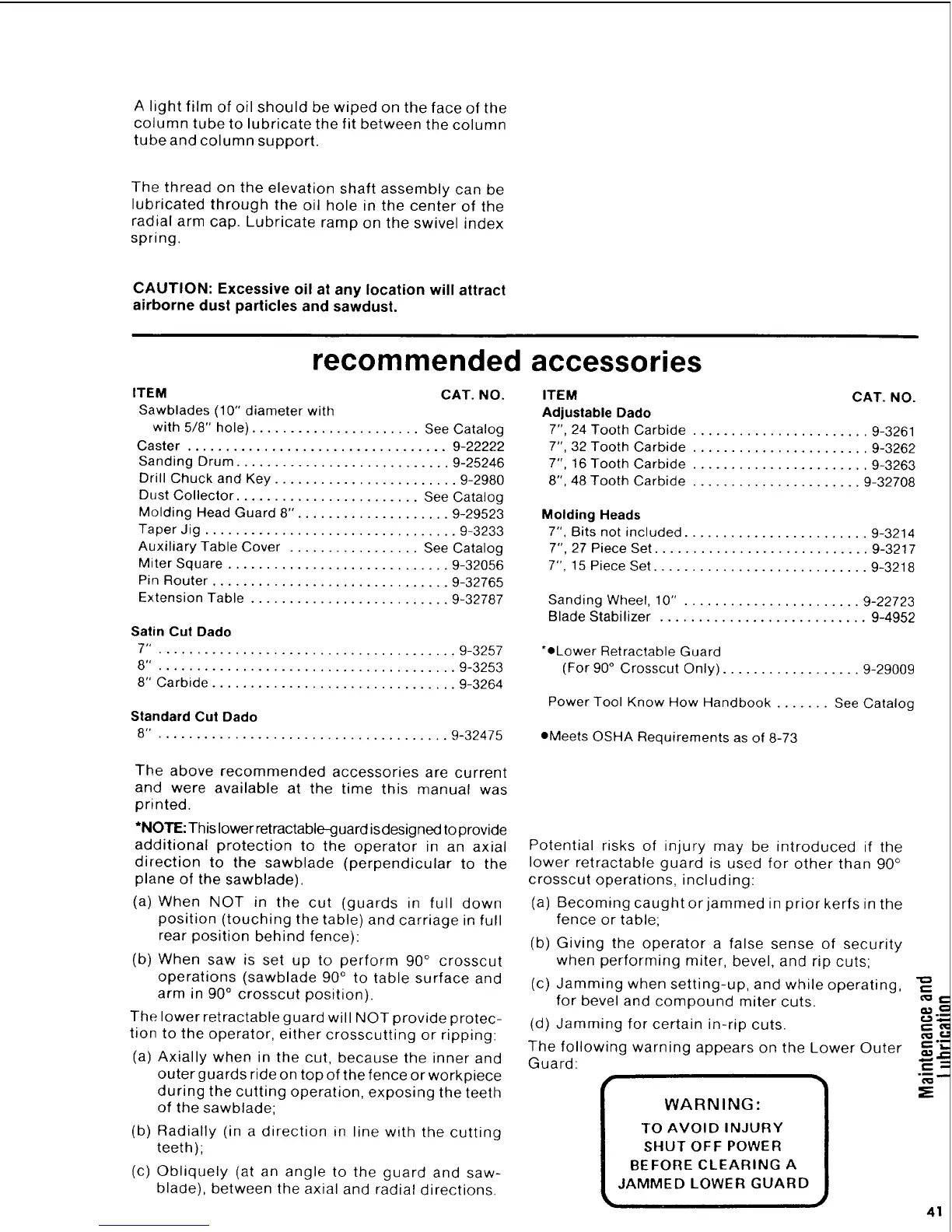

recommended accessories

ITEM CAT. NO.

Sawblades (10" diameter with

with 5/8" hole) ...................... See Catalog

Caster .................................. 9-22222

Sanding Drum ............................ 9-25246

Drill Chuck and Key ........................ 9-2980

Dust Collector ........................ See Catalog

Molding Head Guard 8". ................... 9-29523

Taper Jig ................................. 9-3233

Auxiliary Table Cover ................. See Catalog

Miter Square ............................. 9-32056

Pin Router ............................... 9-32765

Extension Table .......................... 9-32787

Satin Cut Dado

7". ...................................... 9-3257

8". ...................................... 9-3253

8" Carbide ................................ 9-3264

Standard Cut Dado

8" . ..................................... 9-32475

ITEM CAT. NO.

Adjustable Dado

7", 24 Tooth Carbide ....................... 9-3261

7", 32 Tooth Carbide ....................... 9-3262

7", 16 Tooth Carbide ....................... 9-3263

8", 48 Tooth Carbide ...................... 9-32708

Molding Heads

7", Bits not included ........................ 9-3214

7", 27 Piece Set ............................ 9-3217

7", 15 Piece Set ............................ 9-3218

Sanding Wheel, 10" . ...................... 9-22723

Blade Stabilizer ........................... 9-4952

*eLower Retractable Guard

(For 90° Crosscut Only) .................. 9-29009

Power Tool Know How Handbook ....... See Catalog

*Meets OSHA Requirements as of 8-73

The above recommended accessories are current

and were available at the time this manual was

printed.

*NOTE: This lower retractable-guard isdesigned to provide

additional protection to the operator in an axial

direction to the sawblade (perpendicular to the

plane of the sawblade).

(a) When NOT in the cut (guards in full down

position (touching the table) and carriage in full

rear position behind fence):

(b) When saw is set up to perform 90 ° crosscut

operations (sawblade 90 ° to table surface and

arm in 90 ° crosscut position).

The lower retractable guard will NOT provide protec-

tion to the operator, either crosscutting or ripping:

(a) Axially when in the cut, because the inner and

outer guards ride on top of the fence or workpiece

during the cutting operation, exposing the teeth

of the sawblade;

(b) Radially (in a direction in line with the cutting

teeth);

(c) Obliquely (at an angle to the guard and saw-

blade), between the axial and radial directions.

Potential risks of _njury may be introduced if the

lower retractable guard is used for other than 90 °

crosscut operations, including:

(a) Becoming caught or jammed in prior kerfs in the

fence or table;

(b) Giving the operator a false sense of security

when performing miter, bevel, and rip cuts;

(c) Jamming when setting-up, and while operating,

for bevel and compound miter cuts.

(d) Jamming for certain in-rip cuts.

The following warning appears on the Lower Outer

Guard:

WARNING:

TO AVOID INJURY

SHUT OFF POWER

BEFORE CLEARING A

JAMMED LOWER GUARD

€

_'-- e=

t--°_,

_=

=E

41

Loading...

Loading...