Lubrication

Beforelubricating,repairing,orinspecting,alwaysdisengagePTO(Blade I

EngageLever),moveshift leverintoneutral position,set parkingbrake,stopI

eng neandremovekeytopreventun ntendedstart ng. |

l

Pivot Points& Linkage

Lubricateallthepivotpointsonthedrivesystem,parkingbrakeandlift linkageat

leastonceaseasonwith lightoil.

RearWheels

Therearwheelsshouldberemovedfromtheaxlesonceaseason.Lubricatethe

axlesandtherimswellwith anall-purposegreasebeforere-installingthem.

Front Axles

Eachendofthetractor'sfrontpivotbarmaybeequippedwith agreasefitting.

Lubricatewith agreasegunafterevery25hoursoftractoroperation.

Battery

Thebatteryissealedandis maintenance-free.Acidlevelscannotbechecked.

Alwayskeepthebatterycablesandterminalscleanandfreeof corrosive

build-up.

Aftercleaningthe batteryandterminals,applya lightcoatofpetroleumjelly

orgreasetobothterminals.

Alwayskeeptherubberbootpositionedoverthe positiveterminaltoprevent

shorting.

IM PORTANT: Ifremovingthebatteryforanyreason,disconnecttheNEGATIVE

(Black)wirefromitsterminalfirst,followedbythePOSITIVE(Red)wire.When

re-installingthebattery,alwaysconnectthe POSITIVE(Red)wireto itsterminal

first,followedbytheNEGATIVE(Black)wire.Becertainthatthewiresareconnected

tothecorrectterminals;reversingthemcouldchangethe polarityandresultin

damageto yourengine'salternatingsystem.

CleaningBattery

Cleanthebatterybyremovingit fromthetractorandwashingwith a bakingsoda

andwatersolution.Ifnecessary,scrapethebatteryterminalswitha wirebrushto

removedeposits.Coatterminalsandexposedwiringwith greaseorpetroleumjelly

topreventcorrosion.

Battery Failures

Somecommoncausesforbatteryfailureare:

Incorrectinitialactivation

Overcharging

Freezing

Undercharging

Corrodedconnections

ThesefailuresareNOTcoveredbyyourtractor'swarranty.

Cleaningthe EngineAndDeck

Anyfueloroilspilledonthemachineshouldbewipedoffpromptly.DoNOTallow

debristo accumulatearoundthecoolingfinsof theengineoronanyotherpartof

themachine.

IMPORTANT: Theuseofa pressurewashertocleanyourtractorisNOT

recommended.It maycausedamageto electricalcomponents,spindles,pulleys,

bearingsortheengine.

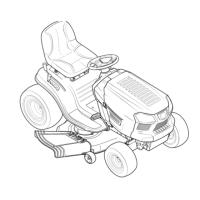

Ascrewanddeckplugcanbefoundonyourtractor'sdecksurfaceasseeninFigure

21.Thisplugcanbereplacedwith awaterporttobeusedaspartofaseparately-

availabledeckwashsystem.

TheDeckWashSystemTM isusedto rinsegrassclippingsfromthedeck'sunderside

andpreventthebuildupofcorrosivechemicals.

NOTE:Adeckwashsystemcanbepurchasedthroughthe retaillocationinwhich

youpurchasedthistractor.Formoreinformation,call1-800-659-5917.

f-

/

Adjustments

Figure21

J

Neverattempt to makeanyadjustmentswhile the engineisrunning,except

wherespecifiedinthe operator'smanual.

Levelingthe Deck

NOTE:Checkthetractor'stirepressurebeforeperforminganydeckleveling

adjustments.RefertoTiresintheServicesectionofthismanualformore

informationregardingtirepressure.

FrontToRear

Thefrontof thecuttingdeckissupportedbyastabilizerbarthat canbeadjustedto

levelthedeckfromfrontto rear.Thefrontofthedeckshouldbebetween1g-inch

and3/8-inchlowerthantherearofthedeck.Adjustif necessaryasfollows:

1. Withthetractorparkedonafirm, levelsurface,placetheleverfor liftingthe

platformonthesecondto thetopnotch(secondhighestposition)androtate

thebladeascloseaspossibleto thedischargechannelthatisparalleltothe

tractor.

Measurethedistancefromthefrontofthebladetip tothegroundandthe

rearofthebladetip totheground.Thefirst measurementtakenshould

bebetweenlg"and3/8"lessthanthesecondmeasurement.Determine

theapproximatedistancenecessaryforproperadjustmentandproceed,if

necessary,to thenextstep.

22

Loading...

Loading...