13

This furnace is manufactured with 2” CPVC vent & intake

couplings. Use transition cement to connect PVC or ABS

pipe to these ttings. For furnaces requiring installation

of 3” pipe, the transition from 2” to 3” should be done as

close to the furnace as possible, and only when the piping

is sloped enough to prevent condensation from collecting.

This furnace must not be connected to Type B, BW, or

L vent or vent connector, and must not be vented into

masonry chimney. A masonry chimney may be used as

a chase or passage way for approved venting materials

providing the masonry chimney is not also being used to

vent products of combustion. Never common vent this

appliance with another appliance. Never use a vent which

is used by a solid fuel appliance.

Piping may run vertically or horizontally and must be

adequately supported to prevent strain on joints, sagging,

separation, and detachment from the furnace. Horizontal

runs of piping must be supported every three to ve

feet. Condensation within the furnace secondary heat

exchanger and in the vent pipe is a normal occurrence.

Vent pipe must be installed to maintain a minimum 1/4

inch per foot downward slope toward the furnace to return

condensate to the furnace’s drain system. Condensation

may also occur in the intake pipe. This commonly takes

place during the summer months when humid air enters

an intake pipe that runs through a cool basement or other

conditioned space. If the combustion air intake pipe is to

be installed above a nished ceiling or other area where

dripping of condensate will be objectionable, insulating

the combustion air pipe may be necessary. Use 1/2” thick

closed cell foam insulation where required. Refer to intake

pipe options for using the RF000142 kit and managing

condensation.

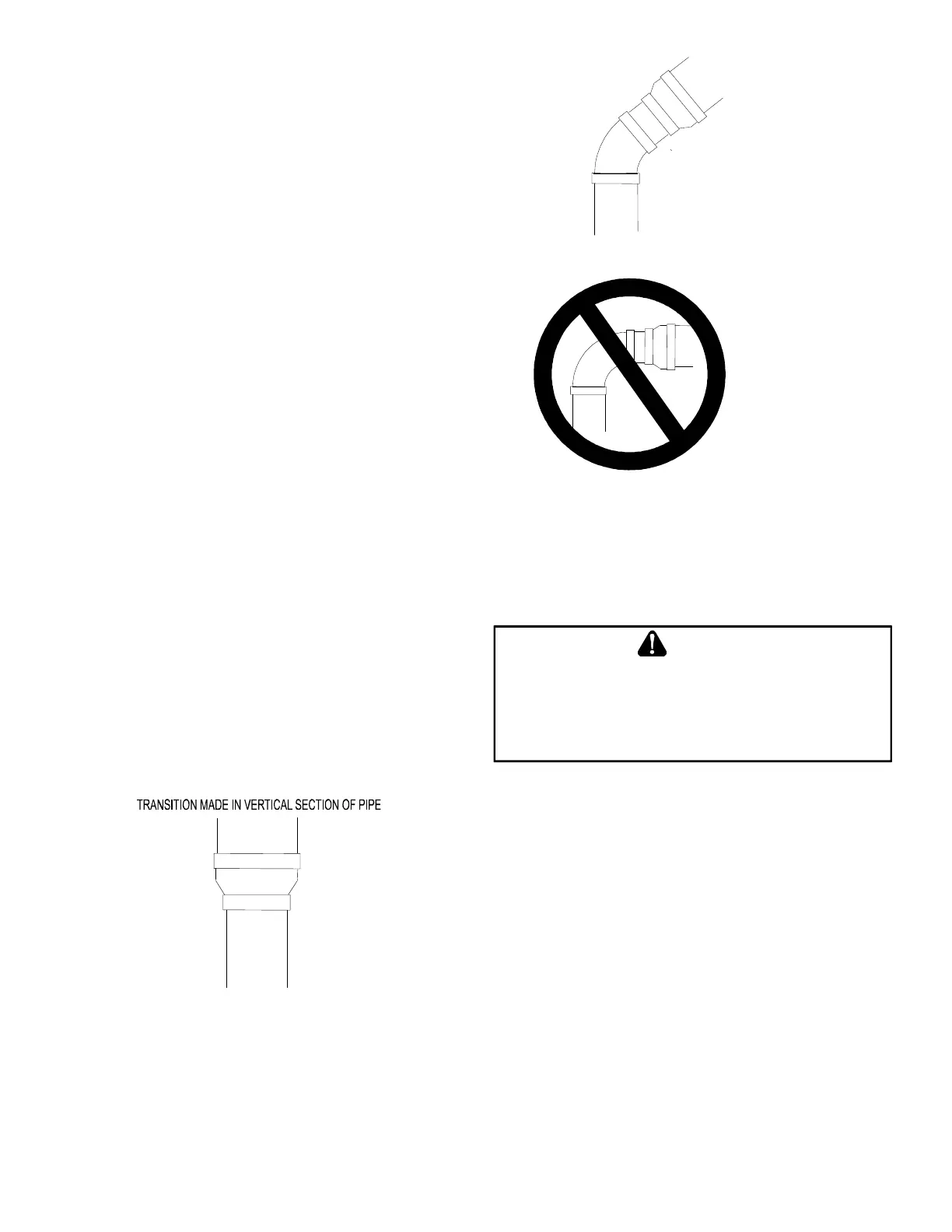

TRANSITION NO LESS

THAN 45 DEGREES TO

HORIZONTAL PLANE TO

AVOID CREATING A WATER

TRAP IN VENT PIPING.

ACCEPTABLE

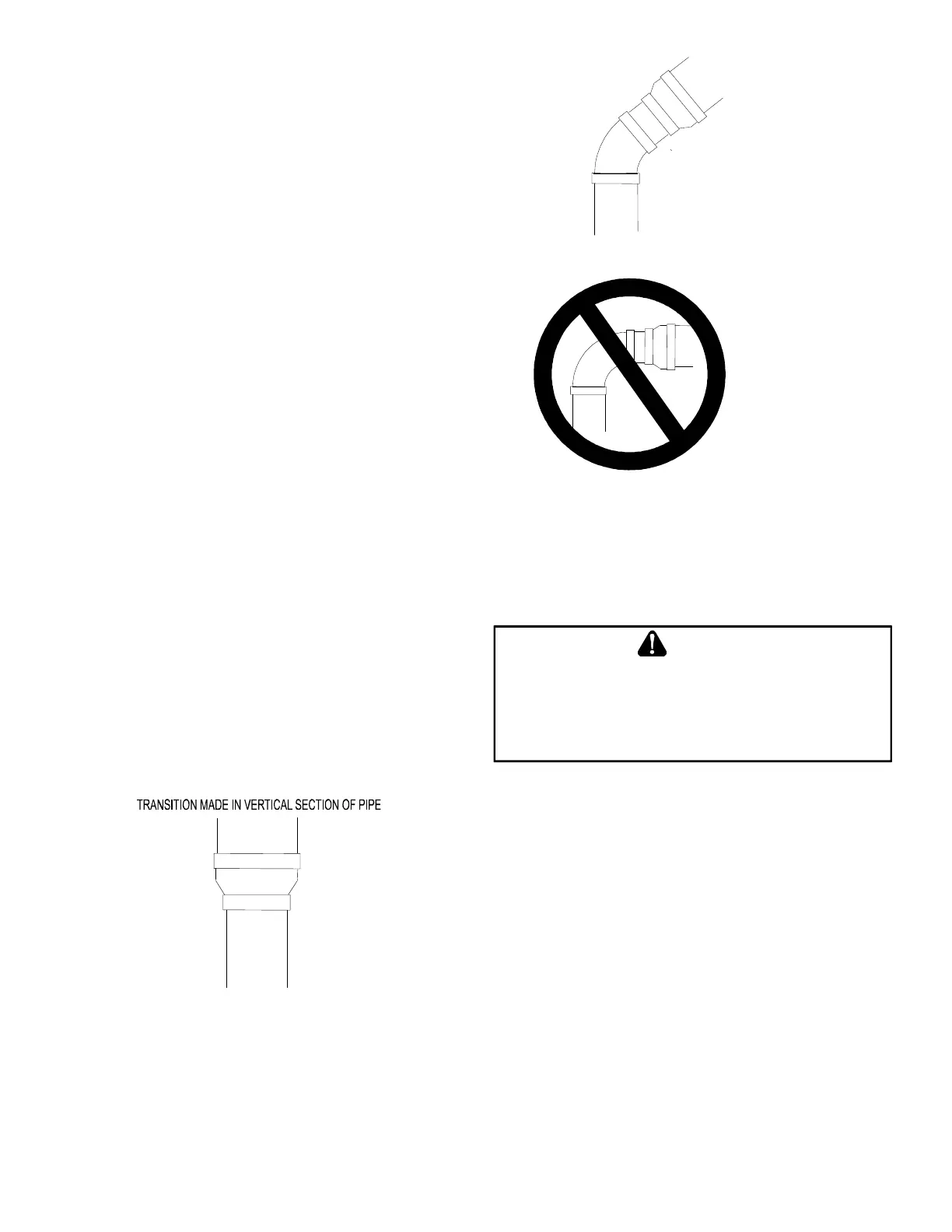

NO TRANSITION ON

HORIZONTAL PLANE,

THIS CREATES A

WATER TRAP AND

RESTRICTS FLUE

GASES

Precautions must be taken to prevent condensate from

freezing inside the vent pipe. All vent piping exposed to

freezing temperatures must be insulated with 1/2” thick

closed cell foam. Inspect piping for leaks prior to installing

insulation.

T

O

AVOID

BODILY

INJURY

,

OR

EXPLOSION

,

SOLVENT

BE

KEPT

ALL

SOURCES

(

I

E

SPARKS

,

OPEN

,

AND

EXCESSIVE

HEAT

)

AS

THEY

ARE

A

VOID

VAPORS

OR

CONTACT

SKIN

AND

/

OR

EYES

Consult tables 4 & 5 to determine what diameter piping is

required for your installation. Lengths shown in the chart

apply to single pipe & two pipe installations. In a two pipe

installation the length shown refers to only one pipe, vent

or intake. Both pipes would normally be equal in length, if

dierent, then the longest pipe must be within the limits of

table 4. It is preferable to up-size from 2” to 2.5” or 3” pipe

if the pipe length & elbow count are near maximum. This

will help avoid nuisance pressure switch opening caused

by prevailing winds & sudden changes in atmospheric

pressure.

Loading...

Loading...