15

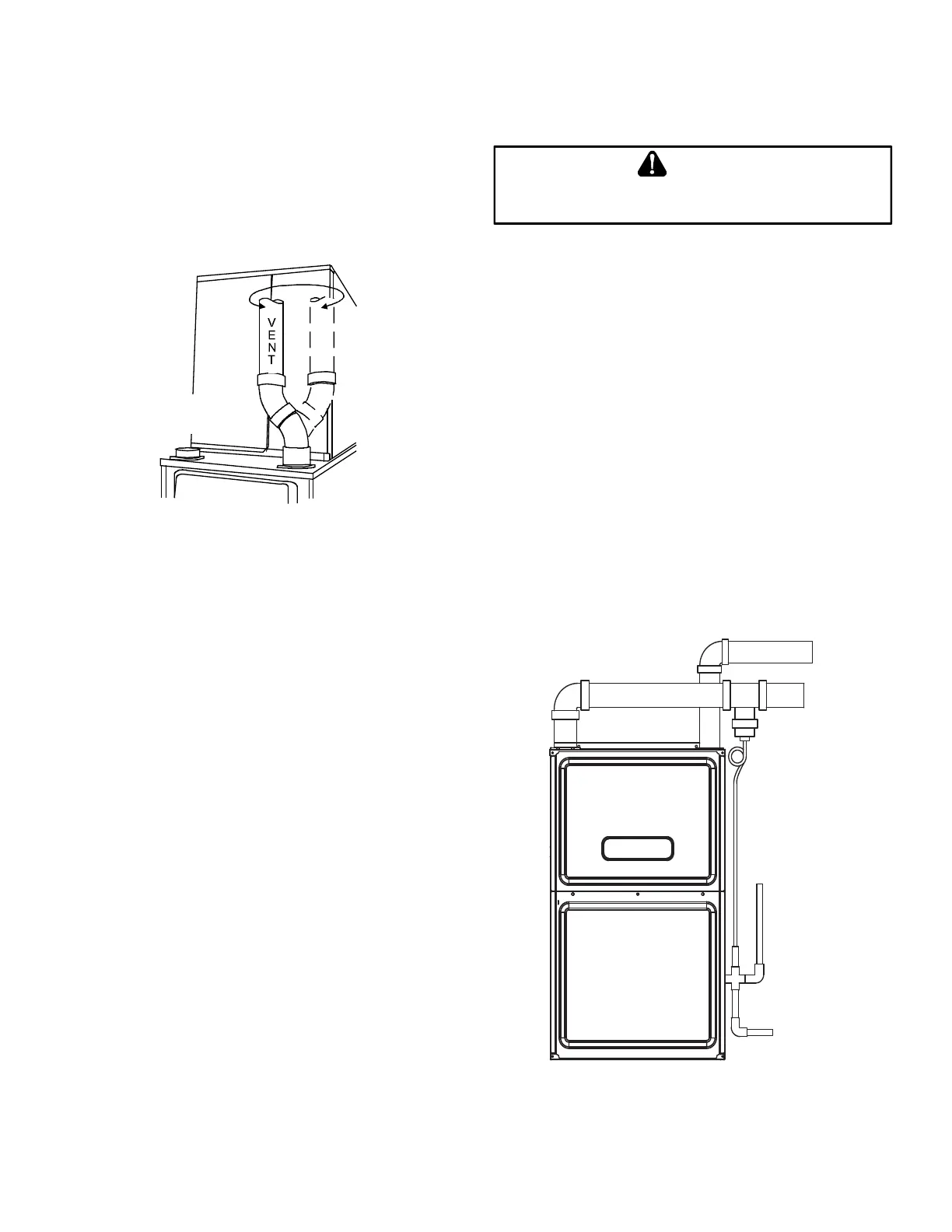

The vent pipe outlet is sized to accept 2” pipe. Secure vent

pipe directly into the furnace tting with the appropriate

glue. Alternately, a small section of 2” pipe may be glued

in the furnace socket and a rubber coupling installed to

allow removal for future service. Piping should be routed in

a manner to avoid contact with refrigerant lines, metering

devices, condensate drain lines, etc. If necessary,

clearances may be increased by creating an oset using

two 45° elbows (Figure 7).

If the furnace is being installed without a combustion air

pipe, a 90° elbow should be used on the combustion air

intake to guard against blockage.

On up ow / horizontal models, secure the combustion

air intake pipe to the air intake coupling using a rubber

coupling supplied with the furnace. The rubber coupling

may be omitted by inverting the intake coupling and gluing

pipe directly to it. Piping may also be glued to the intake

coupling in its original position by using a plastic coupling.

On counterow units secure the combustion air intake

pipe to the air intake coupling using the rubber coupling

and worm gear hose clamps provided with the unit. The

counterow rubber coupling allows service removal of air

intake piping internal to the furnace blower compartment.

The combustion air intake pipe can also be secured

directly to the counterow unit air intake pipe coupling.

The RF000142 coupling (Figure 9) can be secured

directly to the furnace intake coupling if condensation/

rain water is a concern. If the RF000142 is used on the

combustion air inlet, it must be installed with the arrow

pointing up. It should be noted, the combustion air will

actually be moving in a direction opposite of the arrow

on the RF000142 coupling. It must have a eld supplied,

trapped drain tube free-draining to a proper condensate

disposal location. A loop in the drain tube can serve as a

trap. The unused RF000142 drain tting must be capped.

A eld supplied tee installed in the intake pipe is also an

acceptable method of catching condensation. It must have

a eld supplied, trapped drain tube or pipe, free-draining to

a proper condensate disposal location. A loop in the drain

tube can serve as a trap.

E

SHEET

HOLES

BE

SHARP

SE

AS

A

PRECAUTION

HOLE

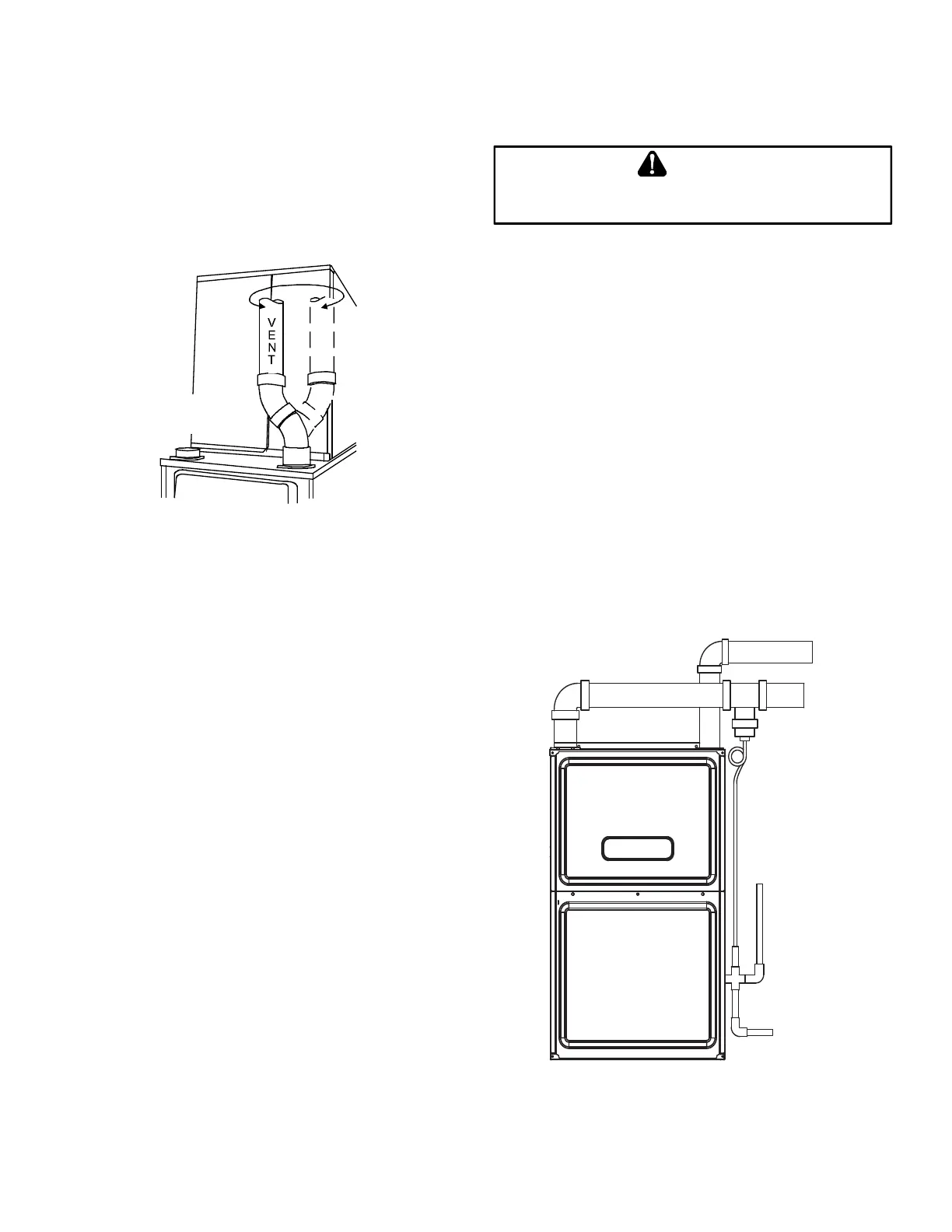

When installing a furnace horizontally with the left side

down, alternate ue and combustion air pipe connections

may be used. This method allows the ue and combustion

air piping to be run vertically through the side of the

furnace (facing up in horizontal left). The alternate vent

location is the 3” hole directly in line with the induced draft

blower outlet.

When using the horizontal alternate vent conguration, you

must use the RF000142 vent drain kit. See Figures 8-11 &

follow steps below.

Loading...

Loading...