28

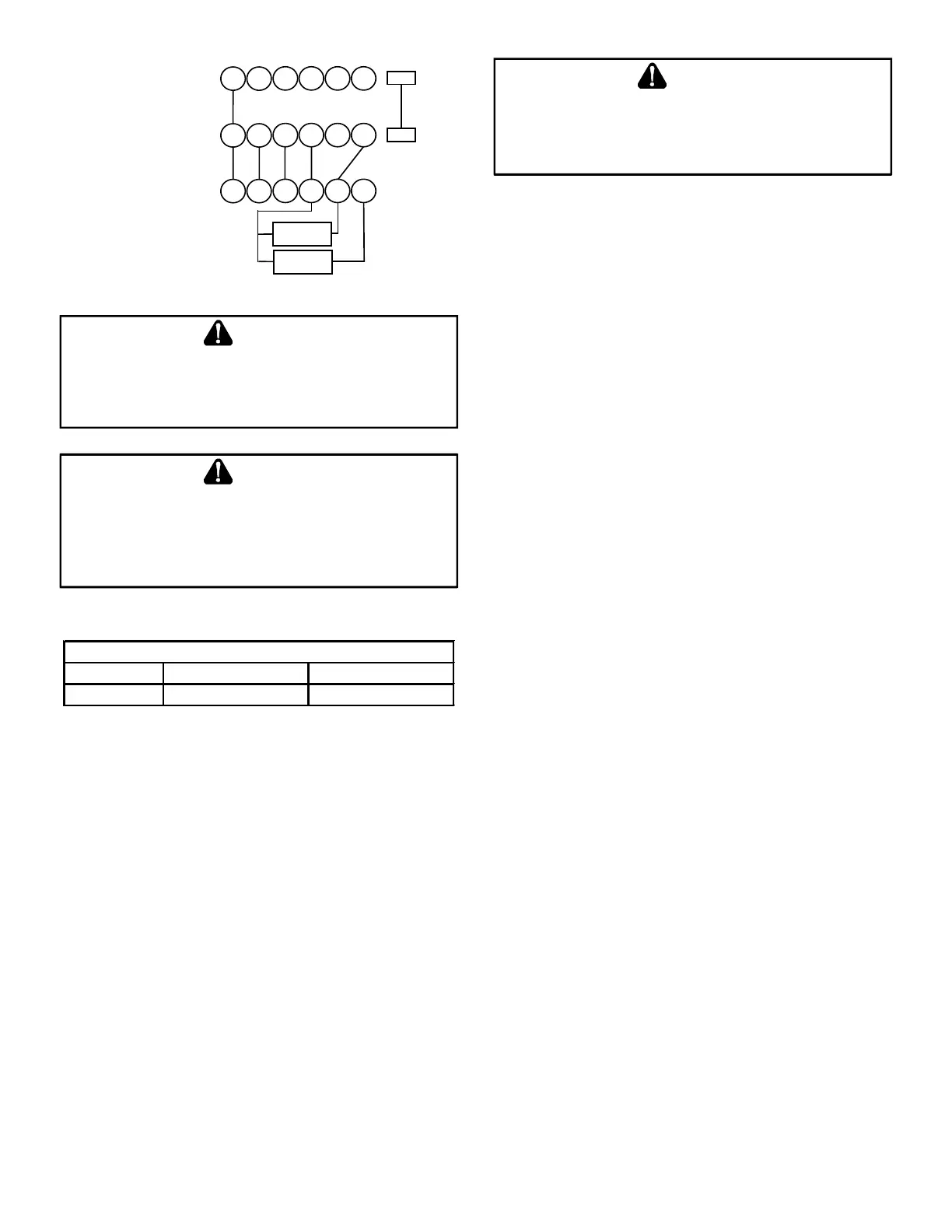

ROOM THERMOSTAT

Y2

Y/Y1

C

G

R

W

Y2

Y/Y1

C

G

R

W

Y2

Y/Y1

C

G

R

W

TWIN

TWIN

COND UNIT

CONTACTOR

COND UNIT

CONTACTOR

FURNACE 1

FURNACE 2

T

O

PREVENT

UNRELIABLE

OPERATION

OR

,

THE

PRESSURE

BE

AS

ON

THE

UNIT

PLATE

NLY

SHOULD

BE

BY

THE

VALVE

PRESSURE

P

OSSIBLE

PROPERTY

,

PERSONAL

INJURY

OR

DEATH

OCCUR

THE

CORRECT

CONVERSION

KITS

ARE

NOT

INSTALLED

HE

APPROPRIATE

KITS

BE

APPLIED

TO

ENSURE

AND

PROPER

OPERATION

LL

CONVERSIONS

BE

BY

A

INSTALLER

OR

SERVICE

Natural Gas Minimum: 4.5" w.c. Maximum: 10.0" w.c.

Propane Gas Minimum: 11.0" w.c. Maximum: 13.0" w.c.

The furnace rating plate includes the approved furnace gas

input rating and gas types. The furnace must be equipped

to operate on the type of gas applied. This includes any

conversion kits required for alternate fuels and/or high

altitude.

Inlet gas supply pressures must be maintained within

the ranges specied in the following table. The supply

pressure must be constant and available with all other

household gas red appliances operating. The minimum

gas supply pressure must be maintained to prevent

unreliable ignition. The maximum must not be exceeded

to prevent unit overring.

T

O

AVOID

POSSIBLE

OPERATION

DUE

TO

OR

,

USE

THE

PROPER

NATURAL

/

PROPANE

NEEDED

PIPE

THE

/

TANK

TO

THE

When this furnace is installed at high altitude, the

appropriate High Altitude Kit including orices and a

pressure switch(s) must be installed. These changes are

necessary to compensate for the natural reduction in the

density of both the gas fuel and the combustion air at

higher altitude.

Installation of this furnace at altitudes above 7000 ft (2134

m), shall be made in accordance with the Listed High

Altitude Conversion Kit available with this furnace.

Do not de-rate the furnace by adjusting the manifold

pressure to a lower pressure than specied on the furnace

rating plate. The combination of the lower air density and

a lower manifold pressure will prohibit the burner orice

from drawing the proper amount of air into the burner. This

may cause incomplete combustion, ashback, and yellow

tipping.

In some areas the gas supplier may articially derate the

gas in an eort to compensate for the eects of altitude.

If the gas is articially derated, the appropriate orice size

must be determined based upon the BTU/ft³ content of

the derated gas and the altitude. Refer to the National

Fuel Gas Code, NFPA 54/ANSI Z223.1, and information

provided by the gas supplier to determine the proper

orice size. A dierent pressure switch may be required

at high altitude regardless of the BTU/ft³ content of the

fuel used. Consult the furnace Specication Sheet. All

conversions must be performed by a qualied installer, or

service agency.

This furnace is shipped from the factory congured for

natural gas at standard altitude. To operate this furnace

on L.P. gas, a LPM-07 LP Conversion kit must be used.

Propane gas installations require an orice and spring

change to compensate for the energy content dierence

between natural and propane gas.

For furnaces being converted to LP gas, it is strongly

recommended that a LPLP03 kit also be installed. The

use of this kit will prevent the furnace from ring when

the LP gas supply pressure is too low to support proper

combustion.

Loading...

Loading...