38

Only small variations in gas pressure should be made by

adjusting the gas valve pressure regulator. The manifold

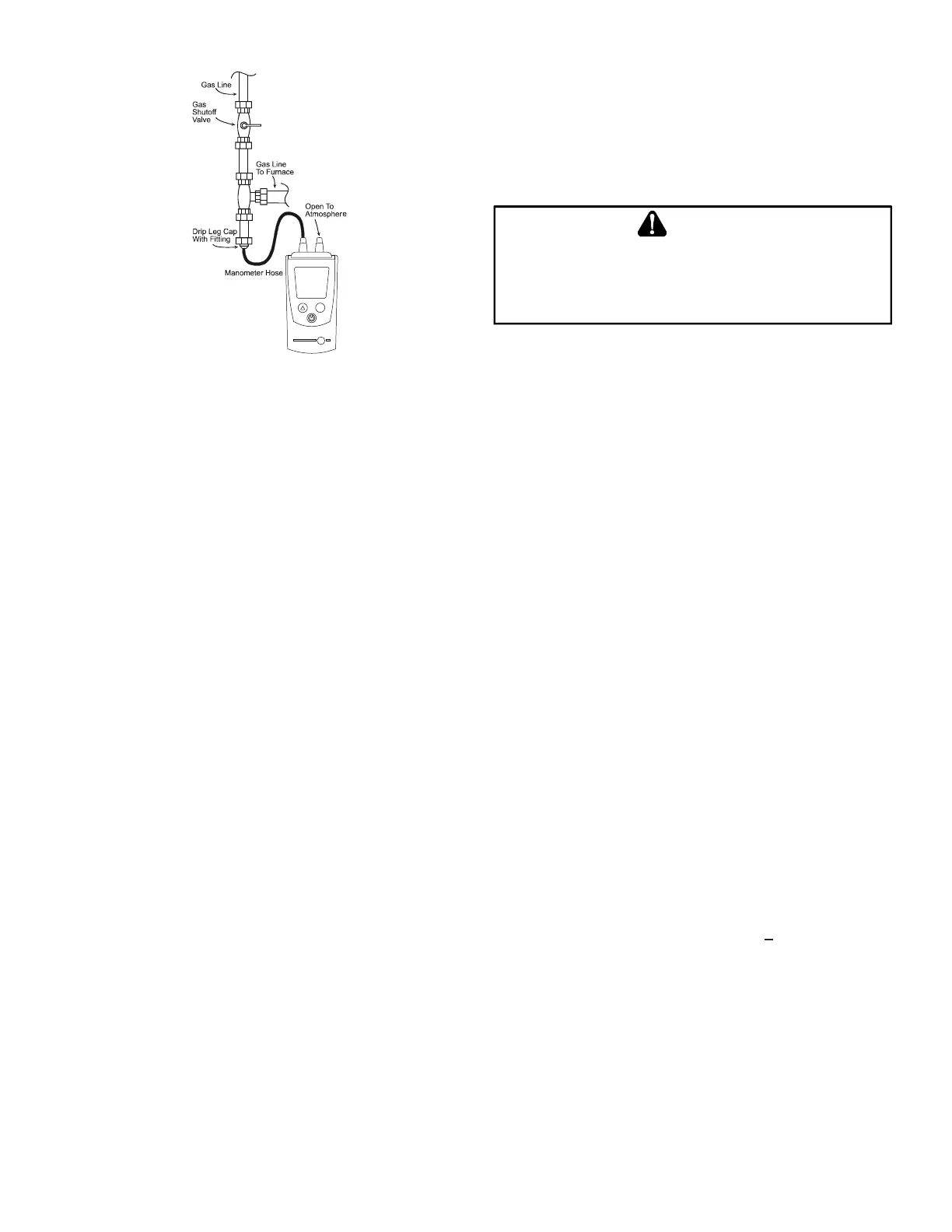

pressure must be measured with the burners operating.

To measure and adjust the manifold pressure, use the

following procedure.

1. Turn OFF gas to furnace at the manual gas shuto

valve external to the furnace.

2. Turn o all electrical power to the system.

3. Outlet pressure tap connections:

White-Rodgers 36J22 valve: Back outlet pressure

test screw (inlet/outlet pressure tap) out one turn

(counterclockwise, not more than one turn).

4. Attach a hose and manometer to the outlet pressure tap

(White-Rodgers valve).

5. Turn ON the gas supply.

6. Turn on power and close thermostat “R” and “W”

contacts to provide a call for heat.

7. Measure the gas manifold pressure with burners

ring. Adjust manifold pressure using the Manifold

Gas Pressure table shown on this page.

8. Remove regulator cover screw from the outlet

pressure regulator adjust tower and turn screw

clockwise to increase pressure or counterclockwise

to decrease pressure. Replace regulator cover

screw.

9. Turn o all electrical power and gas supply to the

system.

10. Remove the manometer hose from the hose barb

tting or outlet pressure tap.

11. Replace outlet pressure tap: White-Rodgers 36J22

valve: Turn outlet pressure test screw in to seal pressure

port (clockwise, 7 in-lb minimum).

12. Turn on electrical power and gas supply to the

system.

13. Close thermostat contacts “R” and “W” to energize the

valve.

Using a leak detection solution or soap suds, check for

leaks at outlet or screw (White-Rodgers valve). Bubbles

forming indicate a leak. SHUT OFF GAS AND REPAIR

ALL LEAKS IMMEDIATELY!

T

O

PREVENT

UNRELIABLE

OPERATION

OR

,

THE

INLET

SUPPLY

PRESSURE

BE

AS

ON

THE

UNIT

PLATE

ALL

OTHER

HOUSEHOLD

APPLIANCES

The actual gas input rate to the furnace must never be

greater than that specied on the unit rating plate. To

measure natural gas input using the gas meter, use the

following procedure.

1. Turn OFF the gas supply to all other gas-burning

appliances except the furnace.

2. While the furnace is operating at high re rate, time

and record one complete revolution of the gas meter

dial, measuring the smallest quantity, usually the dial

that indicates 1/2 cu. ft. per revolution. You will use

this number to calculate the quantity of gas in cubic

ft. if the furnace would consume if it ran steadily for

one hour (3600 seconds).

3. If the 1/2 cu. ft. dial was used, multiply your number

x 2.

EXAMPLE: If it took 23 seconds to complete one

revolution of the 1/2 ft. dial (23 x 2 = 46).

This tells us that at this rate, it would take 46 seconds to

consume one cu. ft. of gas. 3600 / 46 = 78.

This tells us that in one hour, the furnace would consume

78 cu. ft. of gas.

The typical value range for 1 cu. ft. of natural gas is around

1000 BTU. Check with your gas utility, if possible. In this

example, the furnace is consuming 78,000 BTUH.

+

4. Turn ON gas to and relight all other appliances

turned o in step 1. Be certain that all appliances

are functioning properly and that all pilot burners are

operating.

Loading...

Loading...