18 | Piping installation

Installer and user reference guide

92

RXMLQ8 + RXYLQ10~14T7Y1B*

VRV IV system air conditioner

4P543427-1A – 2020.10

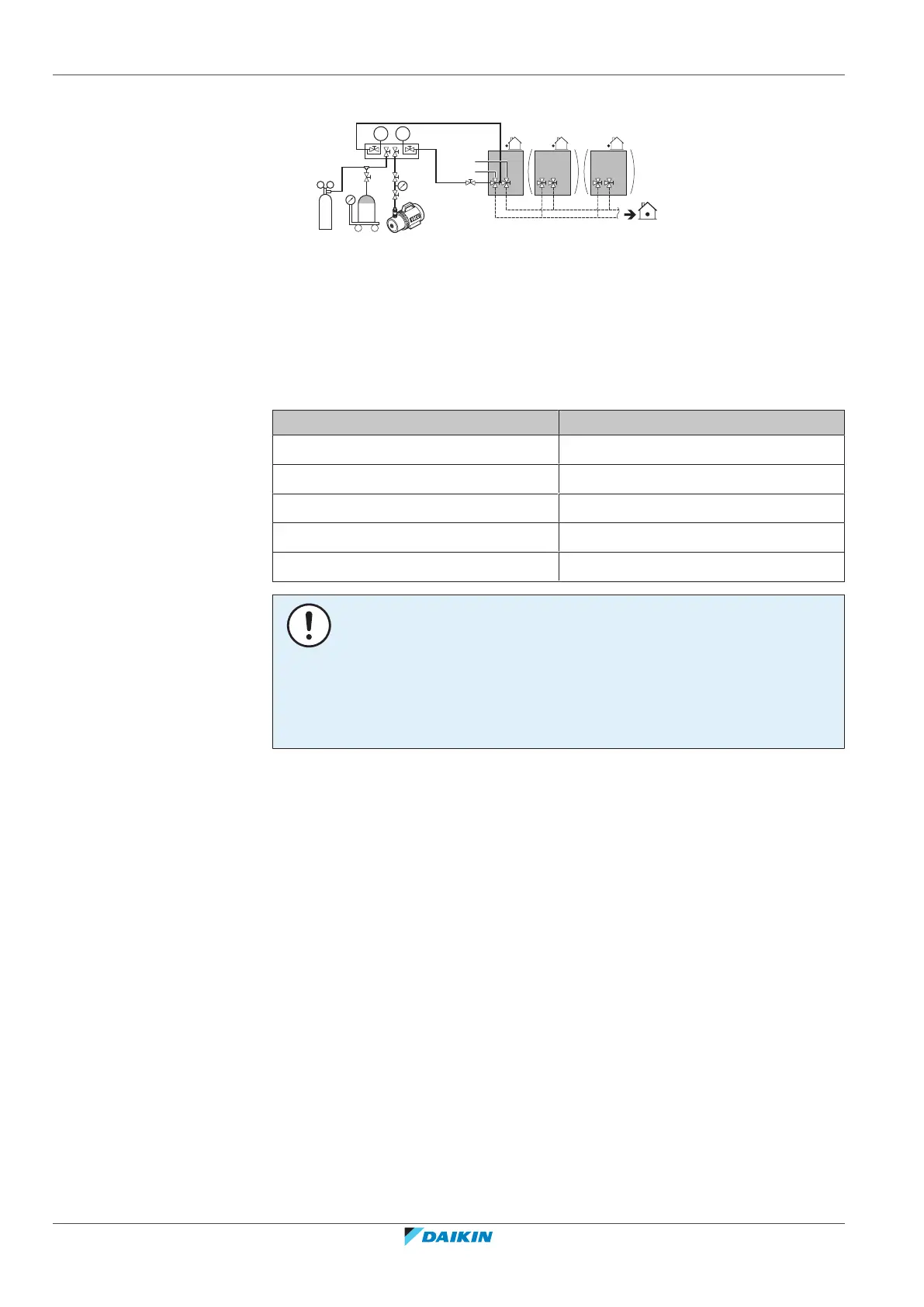

18.3.3 Checking refrigerant piping: Setup

a Pressure reducing valve

b Nitrogen

c Weighing scales

d Refrigerant R410A tank (siphon system)

e Vacuum pump

f Liquid line stop valve

g Gas line stop valve

A Valve A

B Valve B

C Valve C

Valve State of valve

Valve A Open

Valve B Open

Valve C Open

Liquid line stop valve Close

Gas line stop valve Close

NOTICE

The connections to the indoor units and all indoor units should also be leak and

vacuum tested. Keep any possible (field supplied) field piping valves open as well.

Refer to the indoor unit installation manual for more details. Leak test and vacuum

drying should be done before the power supply is set to the unit. If not, see also the

flow chart earlier described in this chapter (see "About checking the refrigerant

piping"[490]).

18.3.4 To perform a leak test

The leak test must satisfy the specifications of EN378‑2.

To check for leaks: Vacuum leak test

1 Evacuate the system from the liquid and gas piping to –100.7kPa (–1.007bar)

(5Torr absolute) for more than 2 hours.

2 Once reached, turn off the vacuum pump and check that the pressure does

not rise for at least 1 minute.

3 Should the pressure rise, the system may either contain moisture (see vacuum

drying below) or have leaks.

To check for leaks: Pressure leak test

1 Test for leaks by applying a bubble test solution to all piping connections.

2 Discharge all nitrogen gas.

3 Break the vacuum by pressurising with nitrogen gas to a minimum gauge

pressure of 0.2 MPa (2 bar). Never set the gauge pressure higher than the

maximum operation pressure of the unit, i.e. 4.0MPa (40bar).

Loading...

Loading...