92 Capacity controller RS8ER302 © Danfoss 2016-02 AK-CH 650

Pump control

The controller can control and monitor one or two pumps that

circulate the brine.

If two pumps are used, and operating time equalisation is se-

lected, the controller can also perform a changeover between the

two pumps if operating alarms occur.

Activity in the case of operating alarm

Pump selection is performed using the following setting:

0: Both pumps are stopped

1: Pump 1 is started up

2: Pump 2 is started up

3: Both pumps are started up

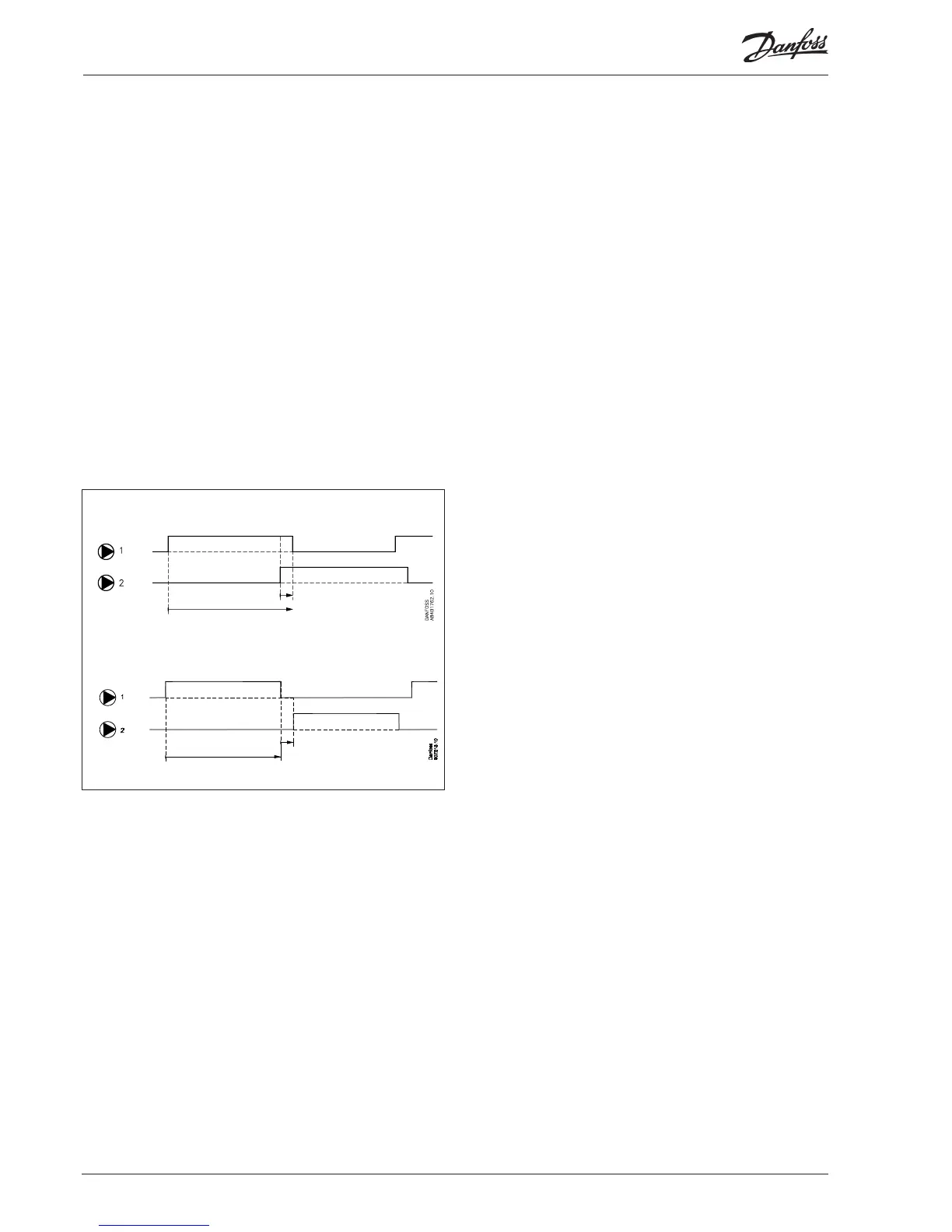

4: Automatic changeover between the pumps is permitted. Start

before stop.

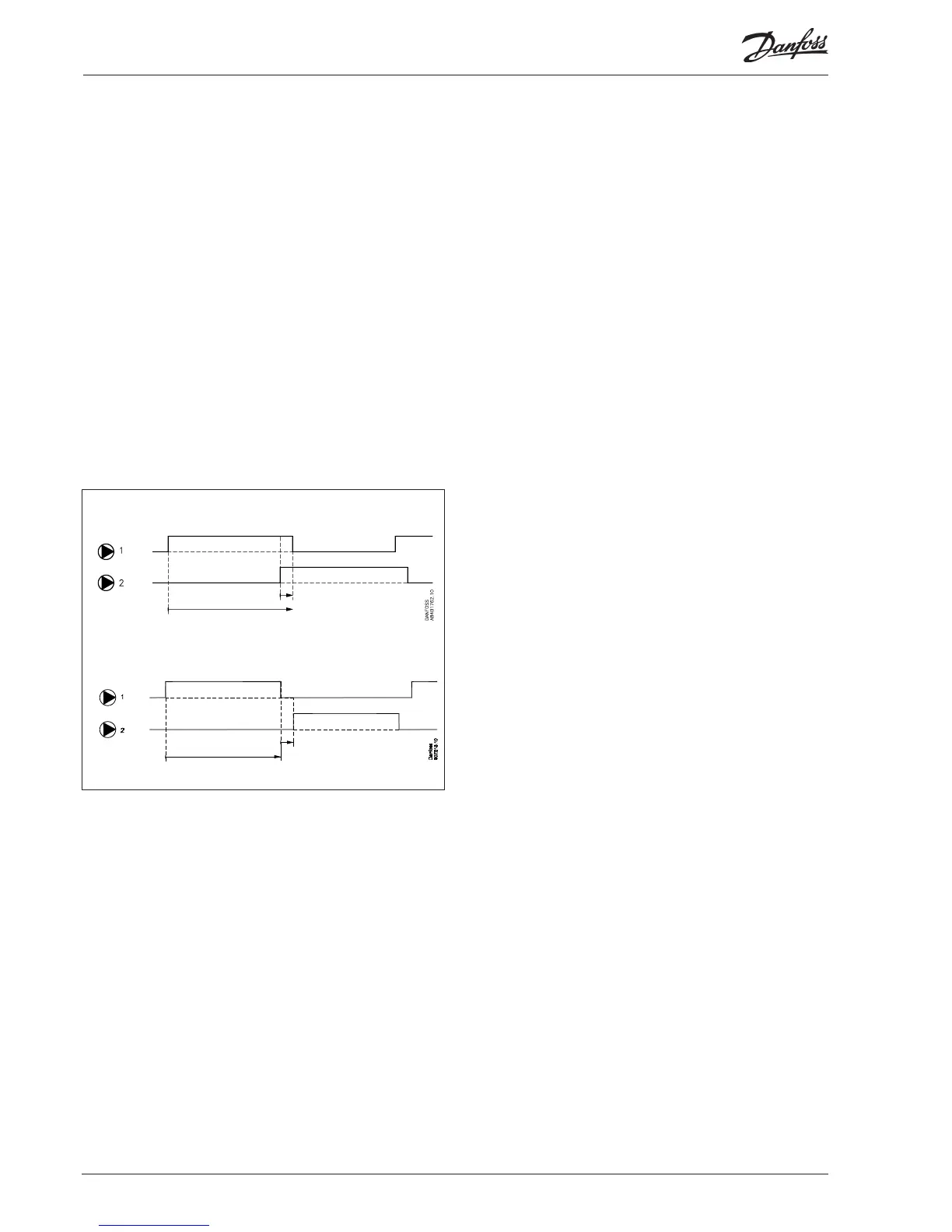

5: Automatic changeover between the pumps is permitted. Stop

before start.

(This function is used when both pumps are controlled in shifts by

the same frequency converter.)

Automatic changeover between the pumps (only for setting = 4

and 5)

Using this setting there can be alternation between the two

pumps so that a type of operating time equalisation is achieved.

The period between the pump changeovers can be set as "Pump-

Cycle". On changeover to the second pump, the rst one will

remain in operation for the "PumpDel" time. It will then stop.

At stop before start "PumpDel" will be the break time for changeo-

ver.

Pump monitoring

The controller monitors pump operation via one or two safety

input.

At one signal the setting "Common" is selected, and the signal

can originate from a pressure dierence pressure switch or a ow

switch.

At two signals the setting "Individual" is selected. The two signals

must then be received at two digital inputs. The signals may be

retrieved from the two motor protectors.

Here too, set an alarm delay time that applies during startup and

on pump changeover.

The delay time is to ensure that on startup/pump changeover, no

error is signalled for a pump before brine ow has been estab-

lished.

The special case of operating time equalisation

If the pumps are running with automatic operating time equalisa-

tion, the controller can perform a changeover of the pumps in a

case where there is no ow.

Depending on whether pump changeover neutralises the alarm

situation or not, the following occurs:

1) Pump changeover neutralises the alarm situation before the

alarm delay expires.

If pump changeover neutralises the alarm situation, the non-

faulty pump, now in operation, will run until the normal cycle

time has expired. After that, there is changeover again to the

"faulty pump", as it is assumed to have been repaired. At the

same time, the alarm situation is reset (the alarm is acknowl-

edged).

If the faulty pump has not been repaired, this will still trigger

an alarm and still result in changeover to the pump that is not

faulty. This is repeated until conditions are returned to normal.

2) Pump changeover does not neutralise the alarm situation

before the alarm delay expires.

If the alarm, on the other hand, is active after pump changeover,

the controller will also emit an alarm for the second pump. At

the same time, both pump outputs are activated in an attempt

to create enough ow for the alarm situation to be neutralised.

From now on, the controller will have both pump outputs

activated until the normal cycle time has expired, after which

the alarm situation is reset and pump changeover to one pump

is performed again.

Separate alarm priorities can be set for drop out of one pump and

for drop out of both pumps. See the Alarms and Messages section.

Alarm handling

Pump alarms are suppressed/acknowledged when normal pump

changeover is performed after the cycle time has expired.

Pump alarms can also be suppressed by setting pump selection

to the "faulty" pump - if the ow switch is OK, the alarm will be

acknowledged/suppressed as a result.

Start before stop

Stop before start

Loading...

Loading...