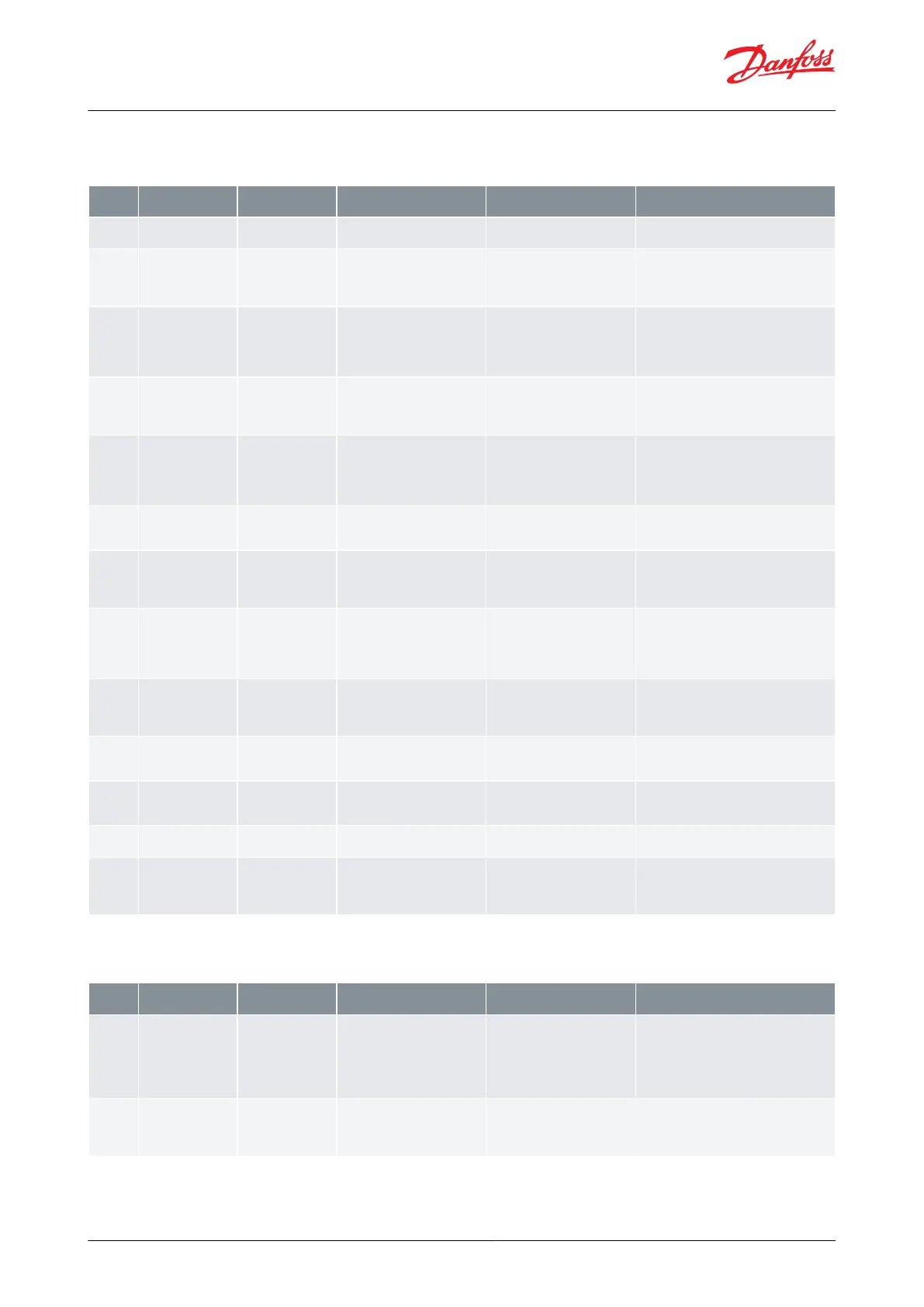

8.1.3 Stepper alarms/errors

Table 57: Stepper alarms/errors

Trigger (how the alarm IS

raised)

I067 valve conguration set

none

I067 valve conguration set a

valve from the list

No valve selected. Please congure the

correct valve in I067 Valve conguration

One or more stepper congura-

tion errors

One or more valve conguration errors is

blocking operation of stepper valve. Check

the other active alarms to identify the

valve conguration problem

check valve step

mode vs positioning

Stepper mode is full step and

half as nal is requested

If full step mode is wanted set

nal positioning to full. If half

step as nal position is wanted,

set step mode to minimum half

step

With 1064 Valve step mode set to "full"

and IO29 Valve step positioning set Half

step operation is possible, Correct either

IO29 or IO64

Combination of step mode and

speed give too few micro speed

per sec (below 8)

Adjust valve speed and/ or

valve step mode to be with lim-

its

Number of micro steps/sec is too high

(higher than 12800 micro step/sec), Re-

duce IO31 Valve speed or use less micro

step per full step (IO64 Valve step mode)

Combination of step mode and

speed give too many micro

speed per sec (higher than

12800)

Adjust valve speed and/ or

valve step mode to be with lim-

its

Number of micro steps/sec is low (higher

than 8 micro step/sec), increase IO31 Valve

speed or increase IO32 Valve start speed or

use more micro step per full step (IO64

Valve step mode)

Valve emergency

speed too fast

Combination of step mode and

speed give too few micro speed

per sec (below 8)

Adjust valve speed and/ or

valve step mode to be with lim-

its

Number of micro steps/sec is too high

(higher than 12800 micro step/sec), Re-

duce IO61 Valve emergency speed

Valve emergency

speed too slow

Combination of step mode and

speed give too many micro

speed per sec (higher than

12800)

Adjust valve speed and/ or

valve step mode to be with lim-

its

Number of micro steps/sec is low (higher

than 8 micro step/sec), increase IO61 Valve

emergency speed

Valve start speed

too slow

Combination of step mode and

speed give too few micro speed

pr sec (below 8)

Adjust valve speed and/ or

valve step mode to be with lim-

its

Number of micro steps/sec is low (higher

than 8 micro step/sec), increase IO31 Valve

speed or increase IO32 Valve start speed or

use more micro step per full step (IO64

Valve step mode)

Valve Short circuit or

driver too hot

Auto operation

blocked, stepper will

try to recover every

10 secs

Stepper driver report thermal

Shutdown,

Stepper driver has recovered

from thermal overload

Valve driver is unable to drive valve. Check

for Short the coils or if ambient is higher

than 60 °C

Battery critical low

voltage

Battery input above 12.2V

Battery voltage is found to be critical low;

valve will not be closed in case of power

fail. Replace battery /check connections

Battery voltage is too high. Valve will not

be closed in case of power fail. Replace

battery with one of correct type (18-24V.).

Battery input above 17.2V

Battery voltage is found to be low, replace

battery.

Auto operation

blocked; stepper will

try to recover every

10 secs

Stepper detect one or 2 open

coils

Current in both coils match

valve prole

Valve have an open circuit on one or more

coils. Check connections to valve.

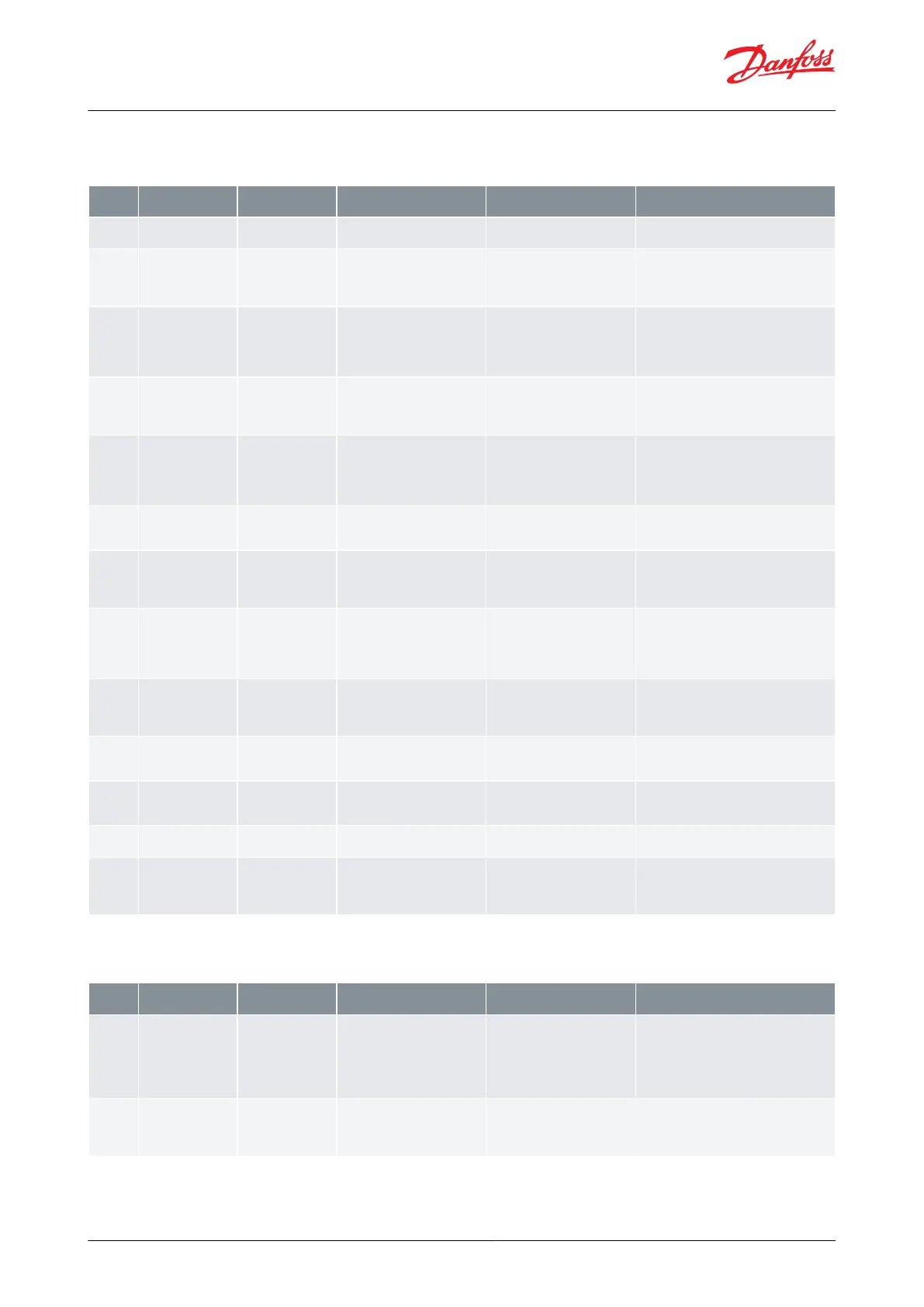

8.1.4 Bus alarms/errors

Table 58: Bus alarms/errors

Trigger (how the alarm IS

raised)

One or more signals (S2, S3, S4,

P0, PC) are not Shared through

CAN within "CAN bus Min. up-

date interval" or Modbus with”

Modbus min. update interval

seconds".

All needed signal is updated at

right frequency

A needed control / sensor / reference sig-

nal via CAN bus is missing. Check CAN bus

connection and operation of other CAN

bus controllers.

Ext. ref. via Modbus

timeout

Bus ext ref. needs to be upda-

ted within "Modbus min. up-

date interval seconds".

Ext reference signal updated

within Modbus min. update in-

terval

A needed control / sensor / reference sig-

nal via Modbus is missing. Check Modbus

connection and operation of other Mod-

bus controllers.

Superheat controller, Type EKE 1A, 1B, 1C, 1D

© Danfoss | Climate Solutions | 2022.06 BC398828796060en-000101 | 74

Loading...

Loading...