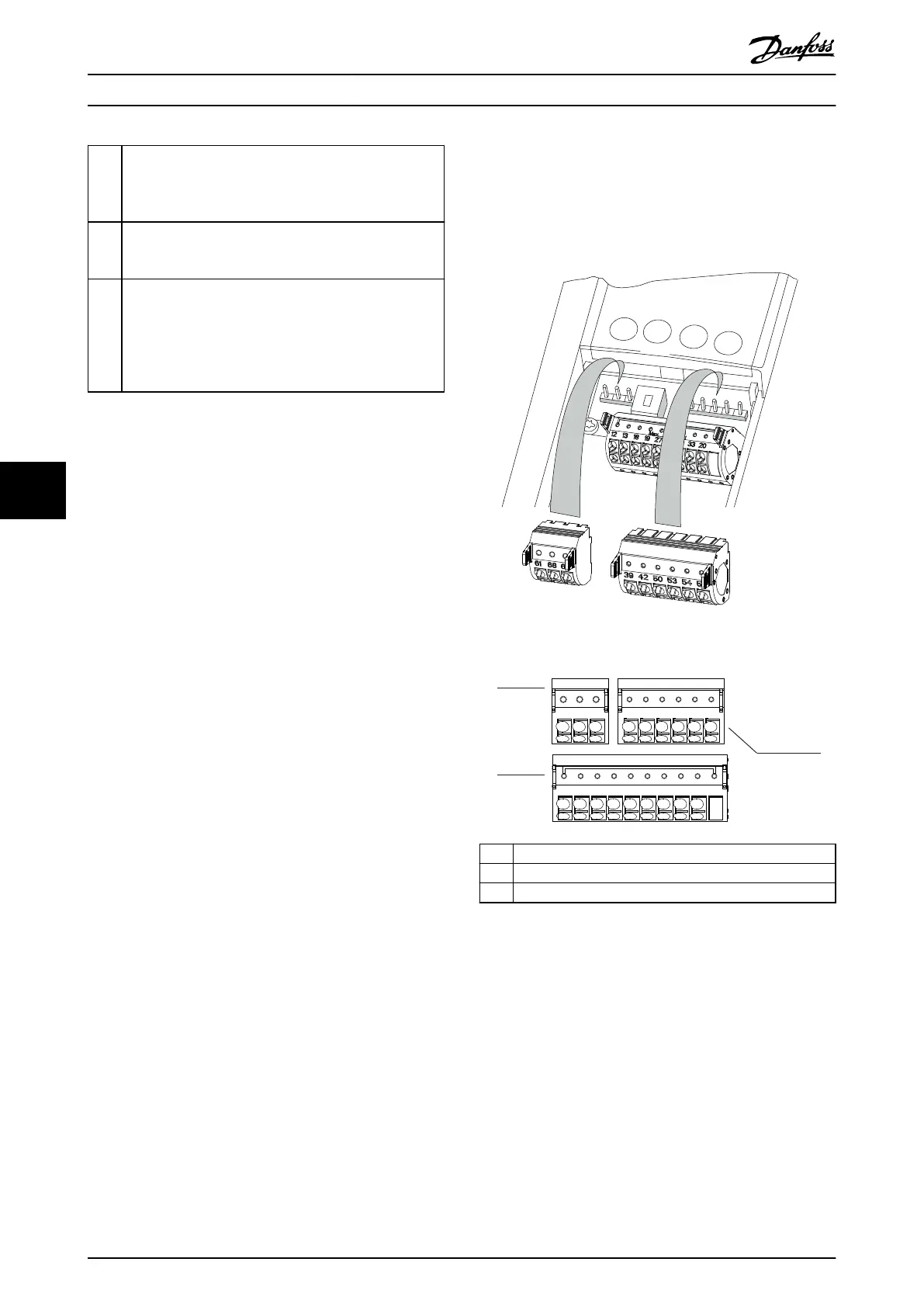

3 If the ground potential between the drive and the PLC is

dierent, electric noise can occur that disturbs the entire

system. Fit an equalizing cable next to the control cable.

Minimum cable cross-section: 16 mm

2

(6 AWG).

4 If long control cables are used, 50/60 Hz ground loops are

possible. Connect 1 end of the shield to ground via a 100

nF capacitor (keeping leads short).

5 When using cables for serial communication, eliminate

low-frequency noise currents between 2 drives by

connecting 1 end of the shield to terminal 61. This

terminal is connected to ground via an internal RC link.

Use twisted-pair cables for reducing the dierential mode

interference between the conductors.

Illustration 7.5 Grounding Examples

7.4.1 Control Cable Routing

Tie down and route all control wires. Remember to

connect the shields in a proper way to ensure optimum

electrical immunity.

•

Isolate control wiring from high-power cables.

•

When the drive is connected to a thermistor,

ensure that the thermistor control wiring is

shielded and reinforced/double insulated. A

24 V DC supply voltage is recommended.

Fieldbus connection

Connections are made to the relevant options on the

control card. See the relevant eldbus instruction. The

cable must be tied down and routed along with other

control wires inside the unit.

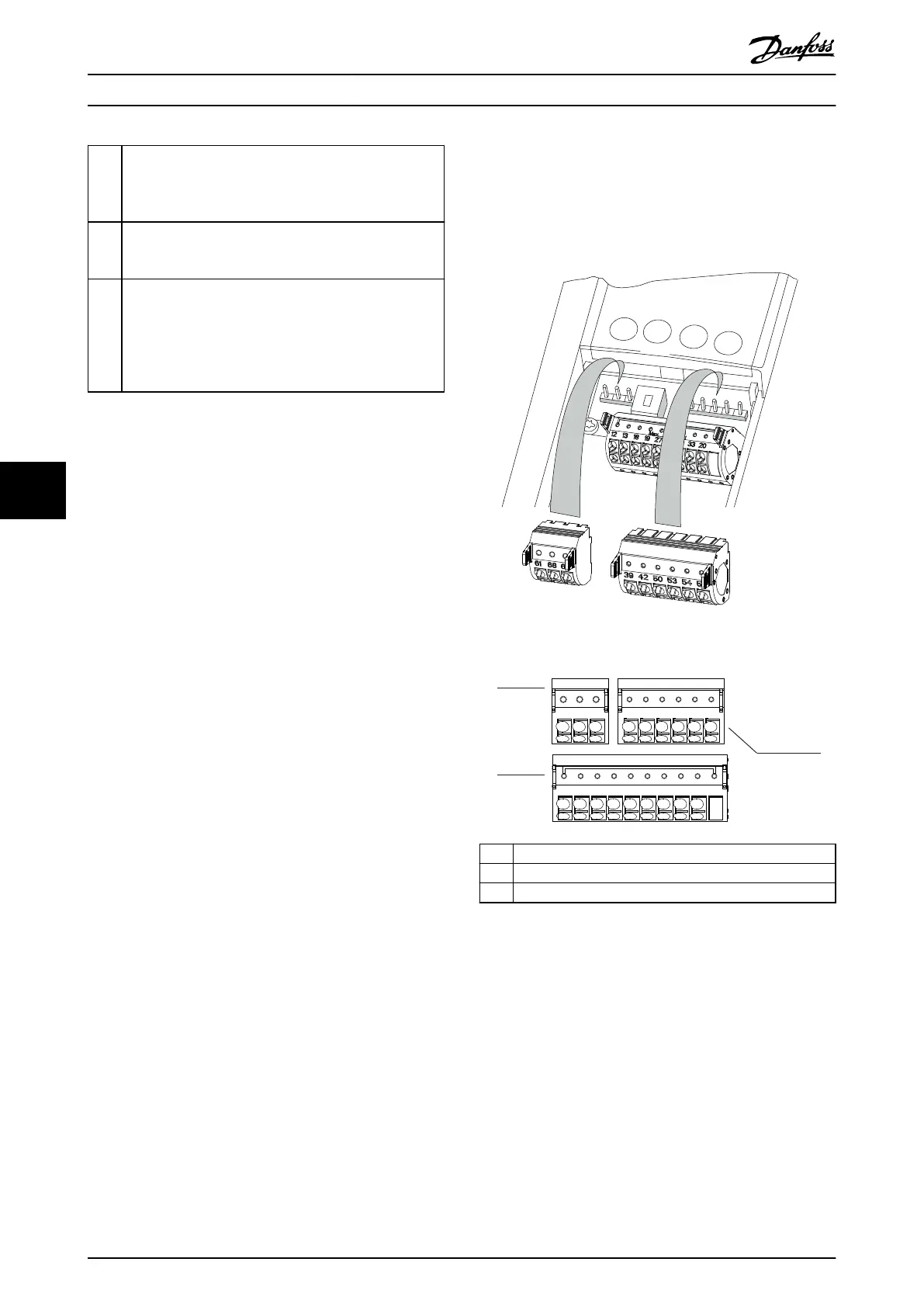

7.4.2 Control Terminals

Illustration 7.6 shows the removable drive connectors.

Terminal functions and default settings are summarized in

Table 7.2 – Table 7.4.

Illustration 7.6 Control Terminal Locations

12 13 18 19 27 29 32 33 20

39696861 42 50 53 54 55

e30bg502.11

1

2

3

1 Serial communication terminals

2 Digital input/output terminals

3 Analog input/output terminals

Illustration 7.7 Terminal Numbers Located on the Connectors

Electrical Installation Con... VLT® AutomationDrive FC 361

42 Danfoss A/S © 03/2019 All rights reserved. MG06K102

77

Loading...

Loading...