Danfoss Drives · DKDD.PB.551.A1.02 | 17

DC braking and soft braking both reduce motor stopping time,

unlike soft stopping which increases the stop time on frictional

loads.

DC braking uses DC injection to reduce the motor’s stopping time.

The soft starter slows the motor to approximately 70% of its full

running speed, then applies brake torque to stop the motor in the

selected braking time.

DC braking support is built into MCD 500 soft starters, and no

additional equipment is required. MCD 500 DC braking controls all

three phases, which reduces stress on the motor compared with

two phase braking solutions.

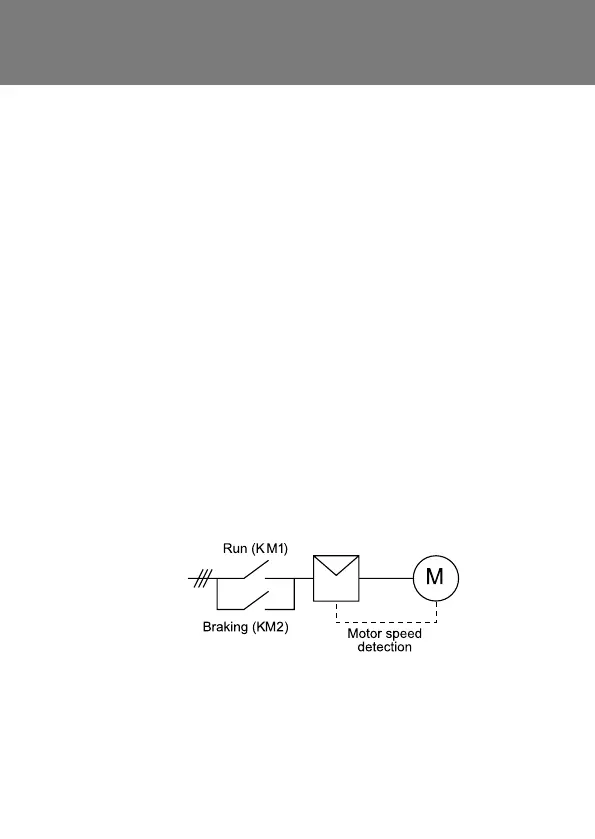

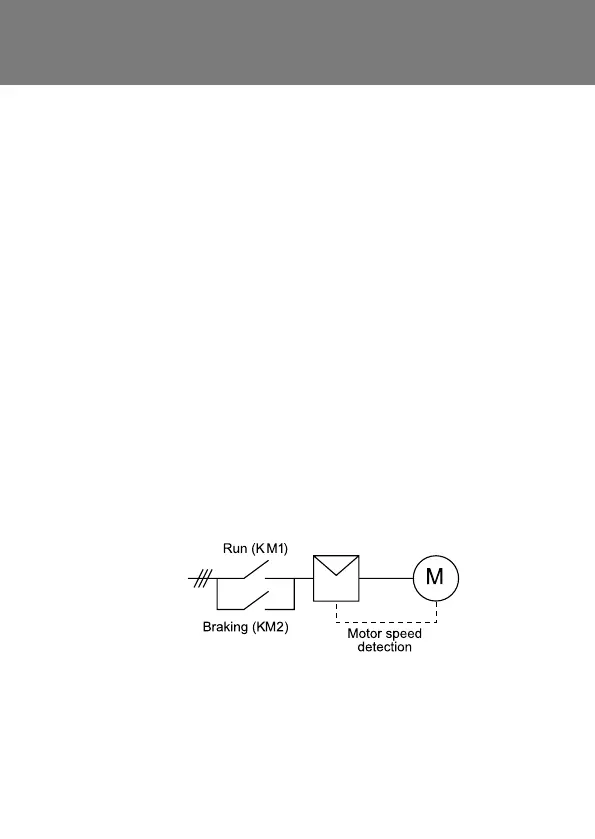

Soft braking uses reversing contactors on the input side of the

starter to start the motor in the reverse direction, which applies

braking torque to the load.

Soft braking causes less motor heating and provides more

braking torque for a given current than DC braking, and is better

for extremely high inertia loads (e.g. band saw and circular saw

applications).

Braking:

What are DC braking and soft braking?

Loading...

Loading...