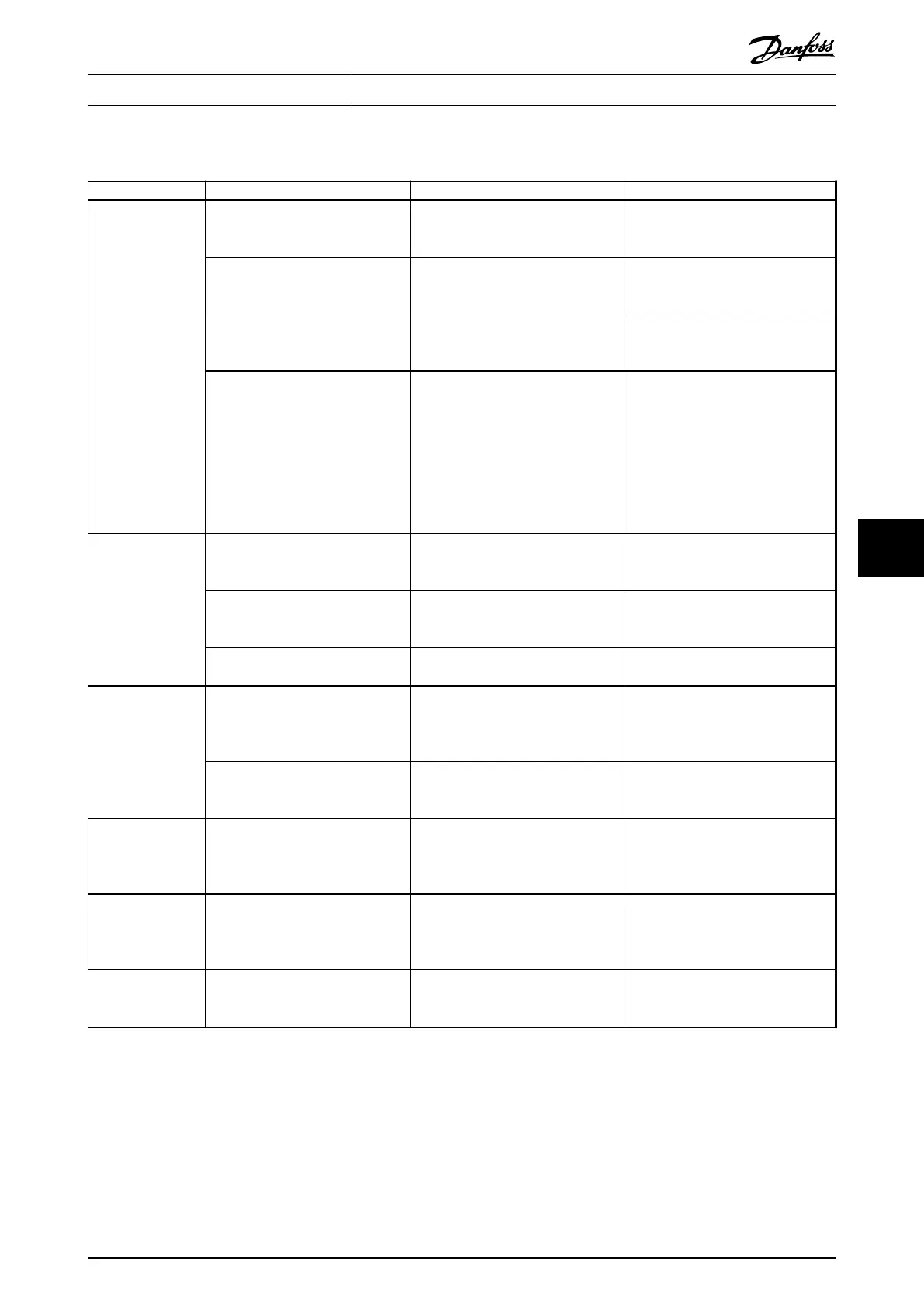

8.5 Troubleshooting

Symptom Possible cause Test Solution

Motor not running

LCP stop Check if [O] has been pressed.

Press [Auto On] or [Hand On]

(depending on operating mode) to

run the motor.

Missing start signal (standby)

Check parameter 5-10 Terminal 18

Digital Input for correct setting for

terminal 18 (use default setting).

Apply a valid start signal to start the

motor.

Motor coast signal active (coasting)

Check parameter 5-12 Terminal 27

Digital Input for correct setting for

terminal 27 (use default setting).

Apply 24 V on terminal 27 or

program this terminal to [0] No

operation..

Wrong reference signal source

Check the following:

•

The reference signal is local,

remote, or bus reference?

•

Preset reference is active?

•

Terminal connection is correct?

•

The scaling of terminals is correct?

•

The reference signal is available?

Program correct settings. Set preset

reference active in parameter group

3-1* References. Check for correct

wiring. Check scaling of terminals.

Check reference signal.

Motor is running in

the wrong direction

Motor rotation limit

Check that parameter 4-10 Motor

Speed Direction is programmed

correctly.

Program correct settings.

Active reversing signal

Check if a reversing command is

programmed for the terminal in

parameter group 5-1* Digital inputs..

Deactivate reversing signal.

Wrong motor phase connection

Change parameter 1-06 Clockwise

Direction.

Motor is not

reaching maximum

speed

Frequency limits are set incorrectly

Check output limits in

parameter 4-14 Motor Speed High Limit

[Hz] and parameter 4-19 Max Output

Frequency.

Program correct limits.

Reference input signal not scaled

correctly

Check reference input signal scaling in

6-** Analog I/O mode and parameter

group 3-1* References.

Program correct settings.

Motor speed is

unstable

Possible incorrect parameter settings

Check the settings of all motor

parameters, including all motor

compensation settings. For closed-

loop operation, check PID settings.

Check settings in parameter group 6-

** Analog I/O mode.

Motor runs roughly Possible overmagnetization

Check for incorrect motor settings in

all motor parameters.

Check motor settings in parameter

groups 1-2* Motor data, 1-3* Adv

motor data, and 1-5* Load indep.

setting.

Motor does not

brake

Possible incorrect settings in the

brake parameters. Possible too short

ramp-down times.

Check brake parameters. Check ramp

time settings.

Check parameter group 2-0* DC brake

and 3-0* Reference limits.

Maintenance, Diagnostics, a... Operating Instructions

MG07A102 Danfoss A/S © 11/2015 All rights reserved. 45

8 8

Loading...

Loading...