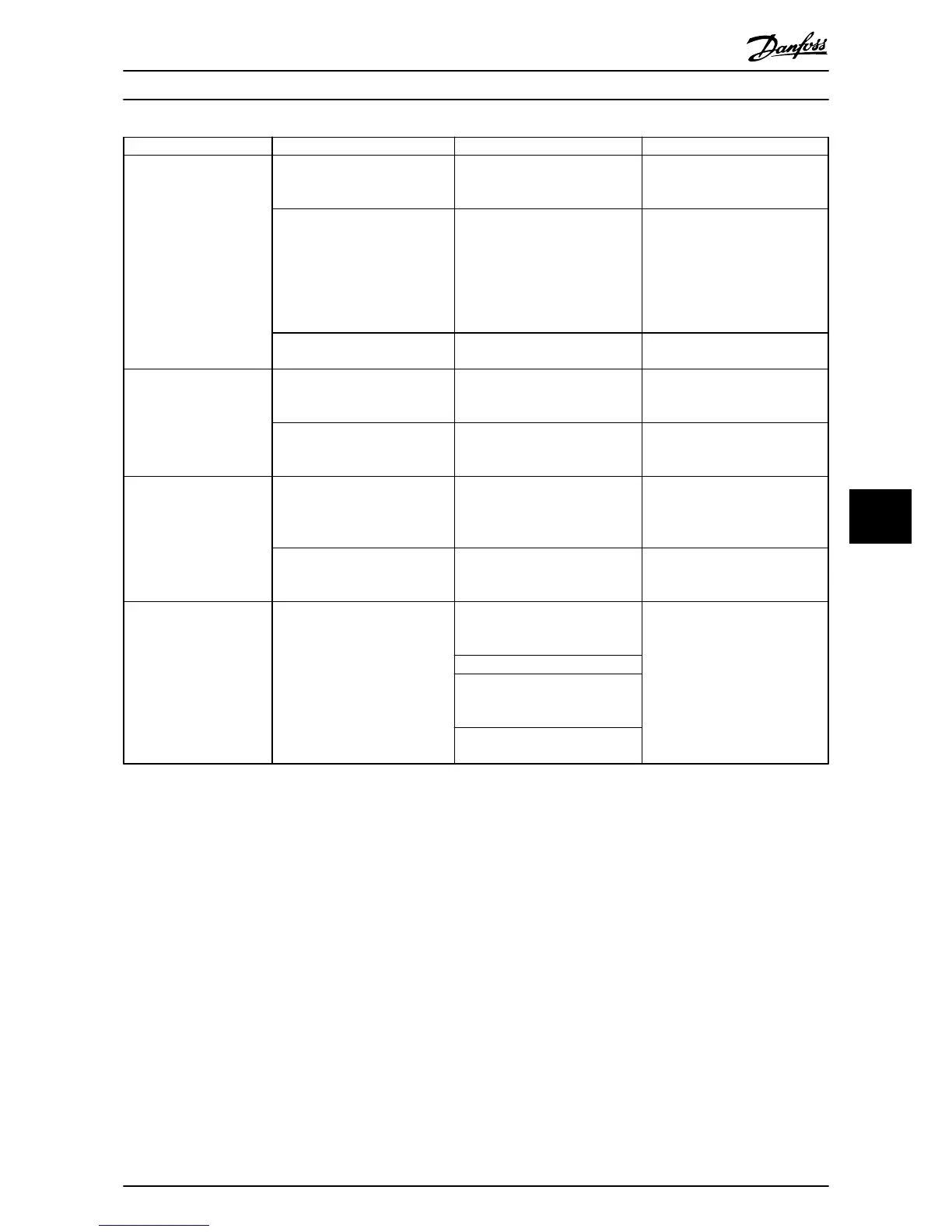

Symptom Possible Cause Test Solution

Open power fuses or circuit

breaker trip

Phase to phase short Motor or panel has a short phase

to phase. Check motor and panel

phase for shorts.

Eliminate any shorts detected.

Motor overload Motor is overloaded for the

application.

Perform startup test and verify

motor current is within specifi-

cations. If motor current is

exceeding nameplate full load

current, motor may run only with

reduced load. Review the specifi-

cations for the application.

Loose connections Perform pre-startup check for loose

connections.

Tighten loose connections.

Mains current imbalance

greater than 3%

Problem with mains power (See

Alarm 4 Mains phase loss

description)

Rotate input power leads into the

drive one position: A to B, B to C, C

to A.

If imbalanced leg follows the wire,

it is a power problem. Check mains

power supply.

Problem with the frequency

converter unit

Rotate input power leads into the

frequency converter one position: A

to B, B to C, C to A.

If imbalance leg stays on same

input terminal, it is a problem with

the unit. Contact the supplier.

Motor current imbalance

greater than 3%

Problem with motor or motor

wiring

Rotate output motor leads one

position: U to V, V to W, W to U.

If imbalanced leg follows the wire,

the problem is in the motor or

motor wiring. Check motor and

motor wiring.

Problem with the drive unit Rotate output motor leads one

position: U to V, V to W, W to U.

If imbalance leg stays on same

output terminal, it is a problem

with the unit. Contact the supplier.

Acoustic noise or vibration

(e.g. a fan blade is making

noise or vibrations at

certain frequencies)

Resonances, e.g. in the motor/fan

system

Bypass critical frequencies by using

parameters in parameter group

4-6*.

Check if noise and/or vibration

have been reduced to an

acceptable limit.

Turn off over-modulation in 14-03.

Change switching pattern and

frequency in parameter group

14-0*.

Increase Resonance Dampening in

1-64.

Table 7.1

Basic Troubleshooting and F...

VLT

®

AutomationDrive FC 360 Quick Guide

MG06A102 - VLT

®

is a registered Danfoss trademark 35

7 7

Loading...

Loading...