M-Class 83

6.3 Printhead Burn Line Adjustment

The Burn Line has been adjusted for strict compliance using 6.5-mil (.0065 inch) media, ensuring print quality across a

majority of media types. In extreme cases, however, if media of a different thickness or rigidity is used (for example,

heavy tag stock), print quality can change.

Note: If you have questions, contact a qualified technician or Datamax

Technical Support before proceeding.

To adjust the Burn Line:

1. Load the printer with your media (and ribbon, if required).

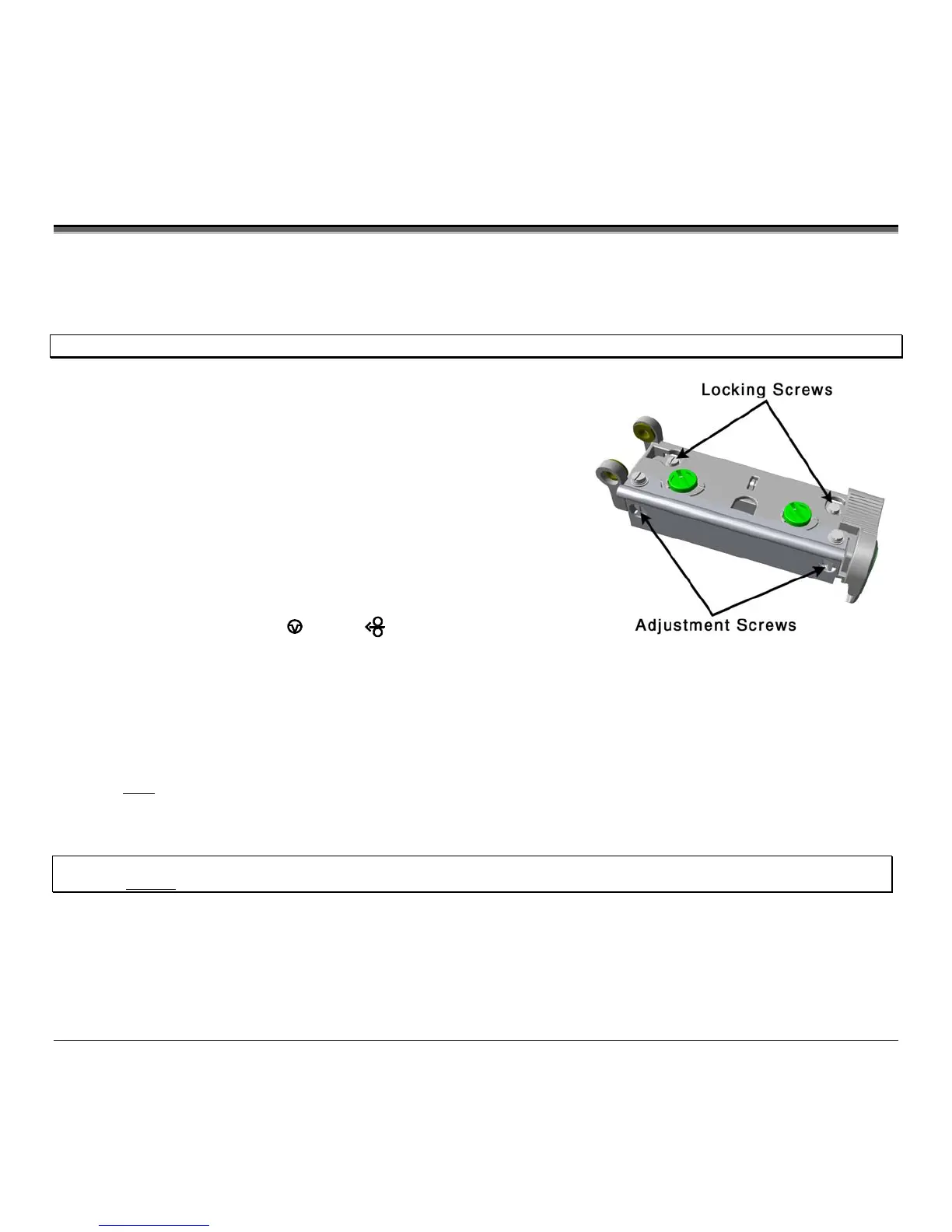

2. Loosen the two Locking Screws approximately ¼ turn counter-

clockwise.

3. Turn the Adjustment Screws counter-clockwise until the burn line is

past the platen roller vertex. Print a test label; the label should look

light and uneven.

Non-display printers:

Simultaneously press the

PAU SE

+

FEED

buttons

Display printers:

See Section 5.3.1

4. Tighten the Locking Screws just until they are ‘snug’ (tight enough to remove any play in the printhead assembly, yet

loose enough to allow the Adjustment Screws to move the printhead).

5. Turn each

Adjustment Screw clockwise about a ¼ turn (or an 1/8 turn for finer adjustments, see note below). Print

another test label and examine the print quality. Repeat this step until labels are produced with even print contrast and

acceptable print quality.

Note: When the Locking Screws are ‘snug’, turning the Adjustment Screws counter-clockwise will NOT move the printhead

outward; if you have adjusted the printhead too far inward, restart the entire procedure.

6. Tighten the Locking Screws then print a final test label to verify the adjustment.

Loading...

Loading...