If the pressure difference is greater than 6 mbar, then the boiler will lock

out. Once the cause of the fault has been remedied, the boiler can be

unlocked by pressing the button for 2 seconds.

4.2.5 Circulating pump

The boiler does not have a built-in pump. A circulating pump can be

installed on the connector of the standard control PCB. This can be an

on/off pump or a modulating pump (with 0 - 10 V control).

The pump settings can be changed.

See

Manual for the control panel.

For more information, see

Analogue output (Ctrl), page 44

4.3

Main components

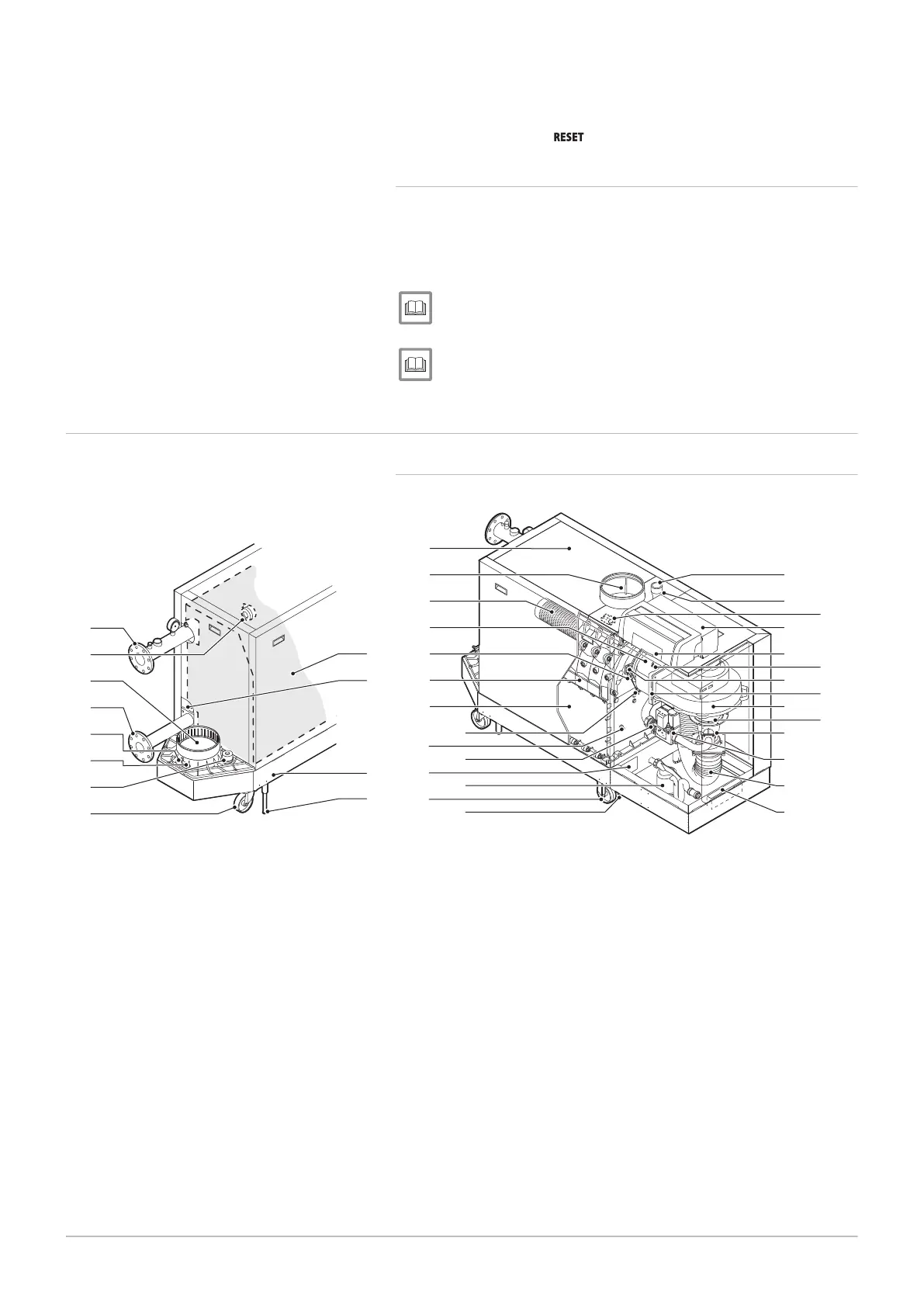

4.3.1 Main components C 330 ECO

Fig.4

C 330 ECO

AD-0000521-01

2

1

3

4

5

6

7

8

27

40

28

29

30

32

34

31

33

35

36

37

38

39

11

12

14

13

15

16

17

18

19

20

22

24

26

21

23

25

10

9

1

Flow connection

2

Air pressure differential switch

3

Flue gas outlet

4

Return connection

5

Flue gas measuring point

6

Flue gas thermostat (if present)

7

Condensate collector sealant cap

8

Pivoting castor

9

Adjustment bolt

10

Frame

11

Second return connection

12

Heat exchanger insulation kit (if present)

13

Boiler casing

14

Air supply

15

Burner

16

Adapter

17

Ignition/ionisation electrode

18

Heat exchanger

19

Inspection trap

20

Temperature sensor for heat exchanger

21

Return temperature sensor

22

Gas filter

23

Data plate

24

Siphon

25

Transport wheels

26

Adjustment bolt

27

Gas connection

28

Gas pressure measuring point

29

Control panel

30

Installation option for weather-compensated boiler

control

31

Pressure measurement point

32

Flame inspection window

33

Non-return valve

34

Fan

35

Extension piece

36

Venturi

37

Gas valve unit

38

Air supply hose

39

Document holder

40

Ignition transformer

4 Description of the product

20 7600532 - v.11 - 13122018

Loading...

Loading...