Appendix C. How to Select the Right AC Motor Drive|VFD-EL-W

210

C-3 How to Choose a Suitable Motor

Standard Motors

When using the AC motor drive to operate a standard three-phase induction motor, follow these

precautions.

The energy loss is greater than that for an inverter-duty motor.

Avoid running the motor at low speed for a long time. Under this condition, the motor temperature

may rise above the motor rating due to limited airflow produced by the motor’s fan. Consider adding

external forced motor cooling.

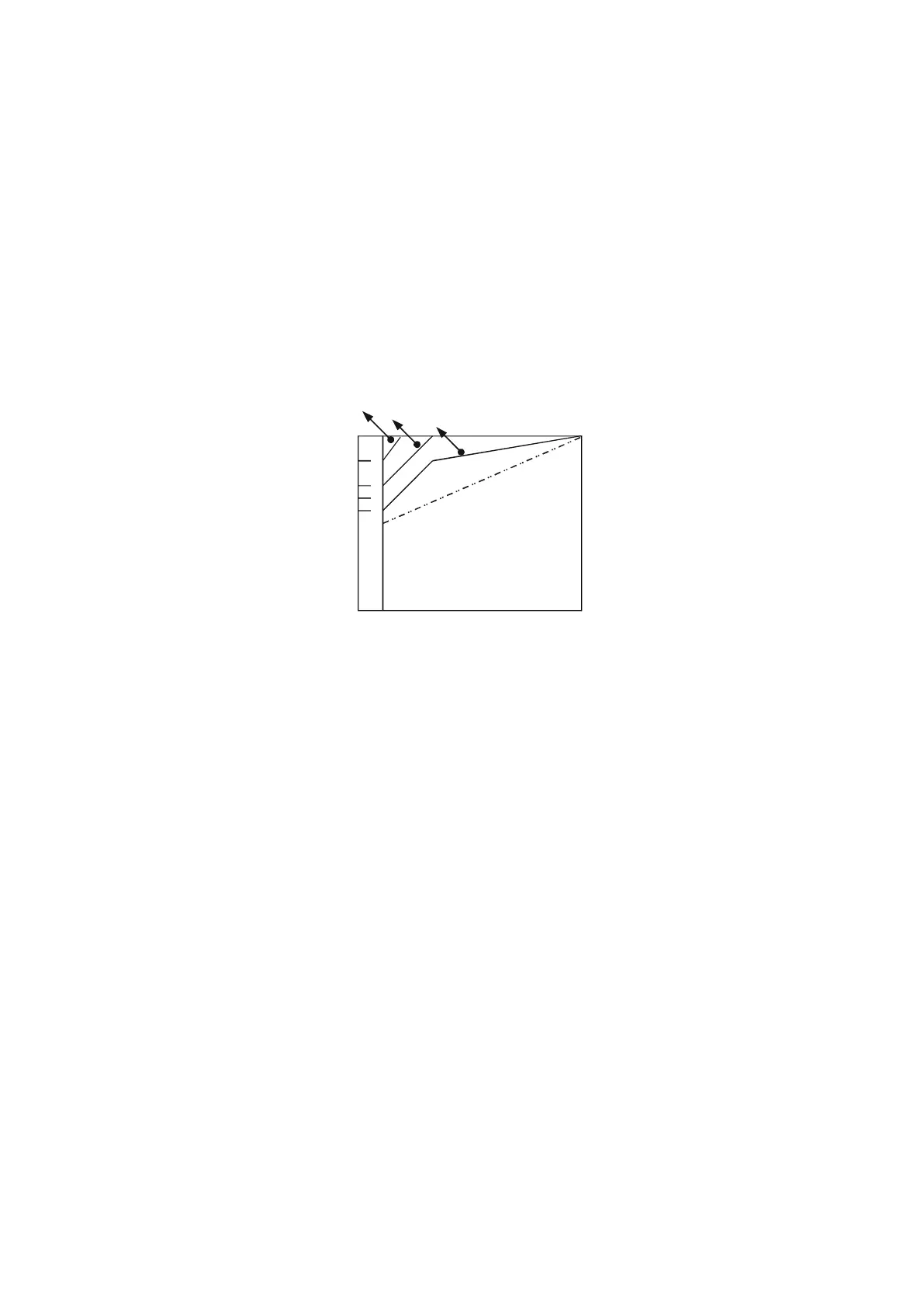

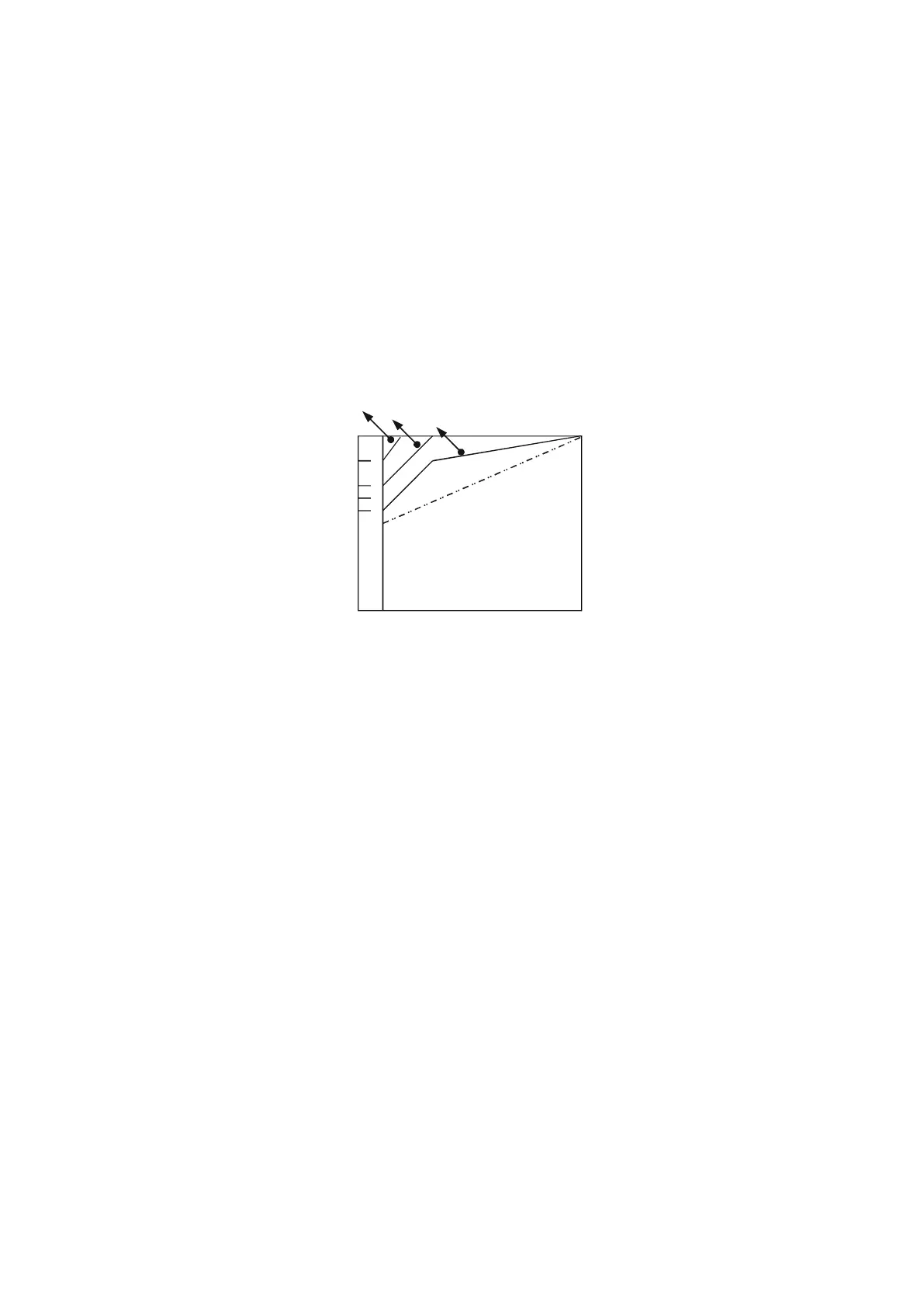

When the standard motor operates at low speed for a long time, the output load must be decreased.

The load tolerance of a standard motor is according to the following diagram.

If 100% of continuous torque is required at low speed, it may be necessary to use a special inverter-

duty motor.

Motor dynamic balance and rotor endurance should be considered once the operating speed

exceeds the rated speed (60Hz) for a standard motor.

Motor torque characteristics vary when driving the motor with an AC motor drive instead of a

commercial power supply. Check the load torque characteristics of the machine connected to the

motor.

Because of the high carrier frequency PWM control of the VFD series, pay attention to the following

motor vibration problems:

Resonant mechanical vibration: use anti-vibration dampers to mount equipment that runs at varying

speed.

Motor imbalance: special care is required for operation at 60 Hz and higher frequencies.

The motor fan is very noisy when the motor speed exceeds 60 Hz or above.

Loading...

Loading...