91

Disassemble the right covering part.

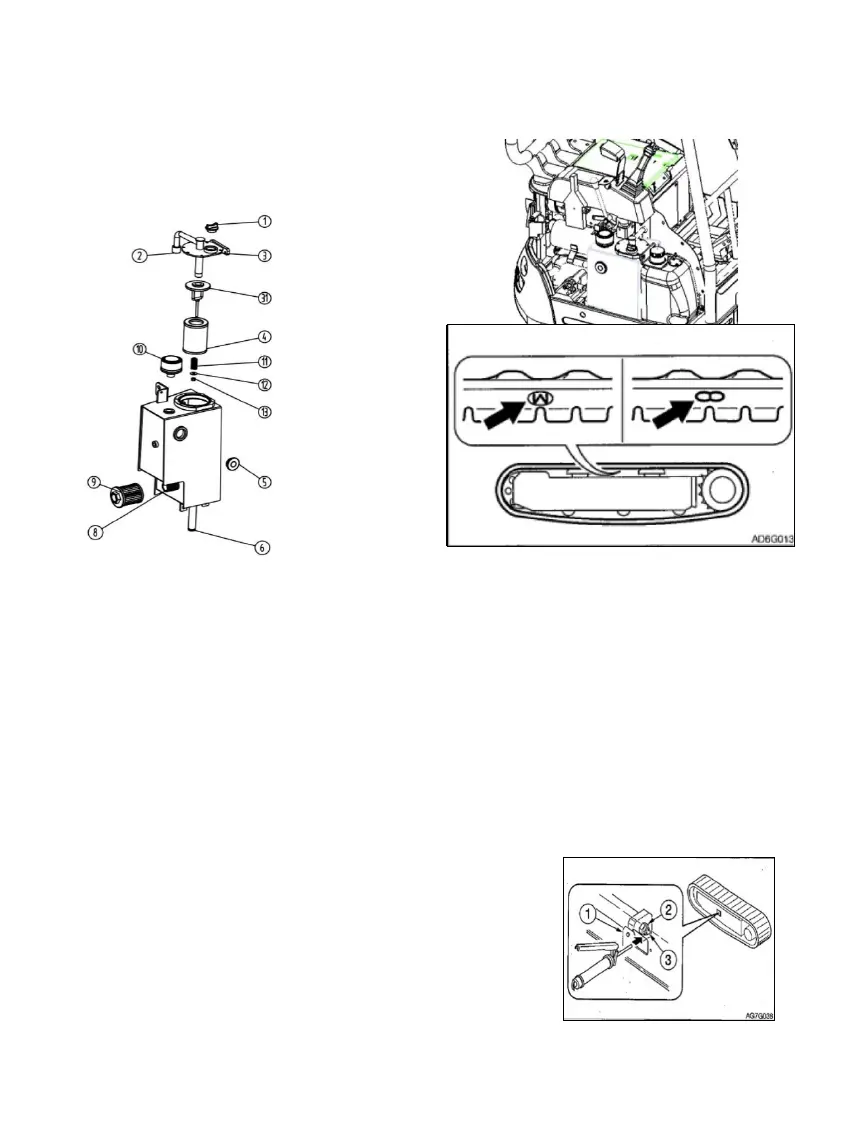

Slowly loosen the bleeding plug (1) to relieve the

internal pressure and then take out the plug.

Loosen the hose band

and take out the hose (2)

from the flange (3).

Loosen the bolt and take

out the flange (3).

Take out the oil

return filter (4).

Install new oil

return filter.

Reinstall flange

(3) and hose (2).

Check the level-

by-level gauge (5).

If the level is too

low, add oil.

Note: For

machine with

ventilator, no pressurization is required.

Every 50h

Checking and Adjustment of Front Toe.

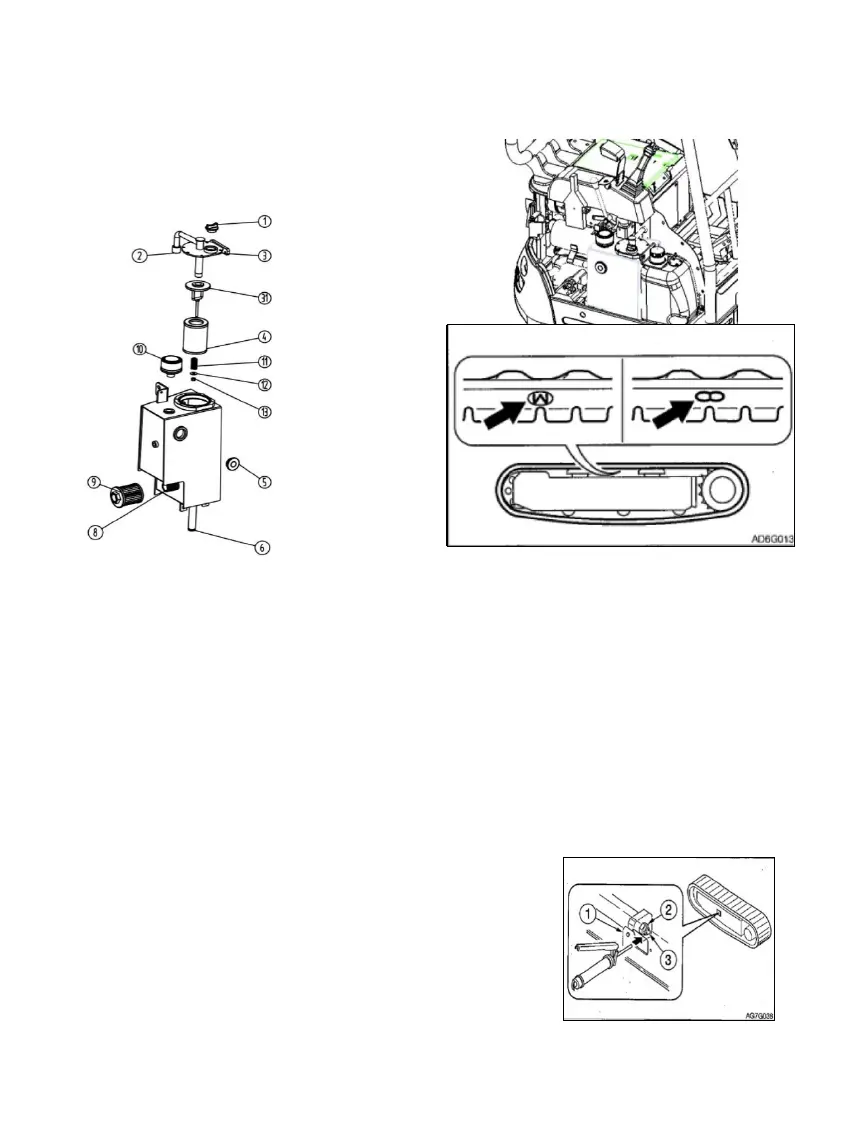

For rubber tracks, adjust the marking “M” at the joints to the top center of track frame.

Lift the machine body by working device.

Slowly operate the joysticks.

Check the track tension.

Check the clearance (A or B) between the frame bottom face and track top face in the middle of

track frame. The clearance (A or B) shall be within following range:

rubber tracks 59~64mm

Steel tracks 95 to 110mm

Adjustment Increasing of Tension

Remove the cover plate.

Slowly loosen (by one turn) the grease relief valve (2) by a

wrench to drain the grease. If it’s difficult to drain the grease,

drive the machine back and forth.

Tighten the grease relief valve (2).

Tightening torque: 177 N˙M

Loading...

Loading...