13type vsa12, vsa12b, vsa16, vsa20, and vsa20a operation and installation instructions MN280063EN May 2017

Operation

WARNING

This equipment is not intended to protect human

life. Follow all locally approved procedures and safety

practices when installing or operating this equipment.

Failure to comply can result in death, severe personal

injury, and equipment damage.

G102.1

WARNING

Hazardous voltage. Always use a hotstick when working

with this equipment. Failure to do so could result in

contact with high voltage, which will cause death or

severe personal injury.

G108.1

WARNING

Hazardous voltage. Do not rely on the open position

of the yellow operating handle or the contact position

indicator; it does not ensure that the line has been

de-energized. Always establish a visible disconnect.

Failure to follow proper safety practices can result in

contact with high voltage, which will cause death or

severe personal injury.

G114.1

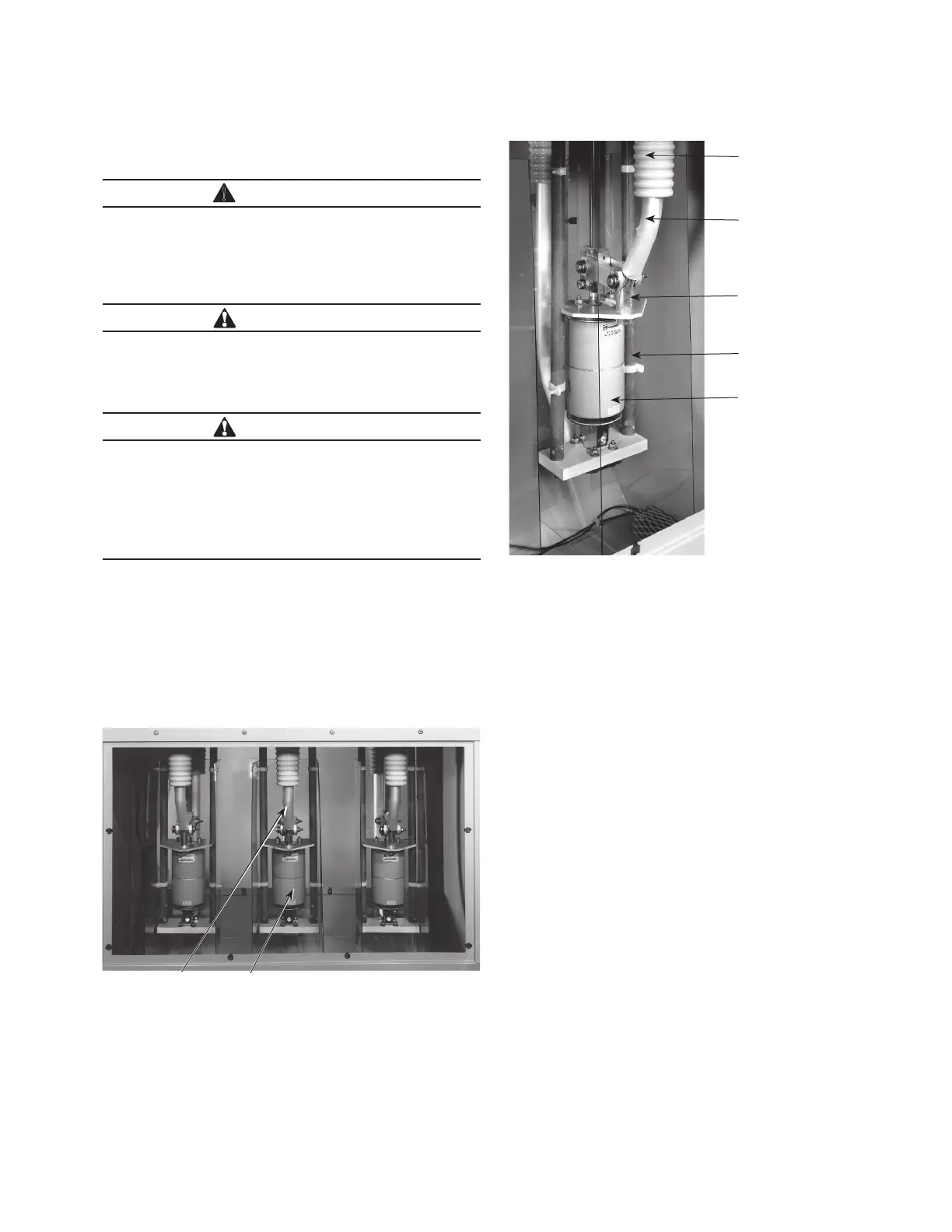

VSA three-phase reclosers feature vacuum interruption and

air insulation. Current interruption takes place in the vacuum

interrupter assemblies that are suspended from the recloser

cover by insulating supports. See Figures 12 and 13. The

moving contacts, which are located in each interrupter

assembly and driven by the recloser operating mechanism,

close or open the circuit. Arc interruption takes place within

one cycle while utilizing a stroke of approximately one-half

inch.

Figure 12. Type VSA20 vacuum recloser with inspection

cover removed.

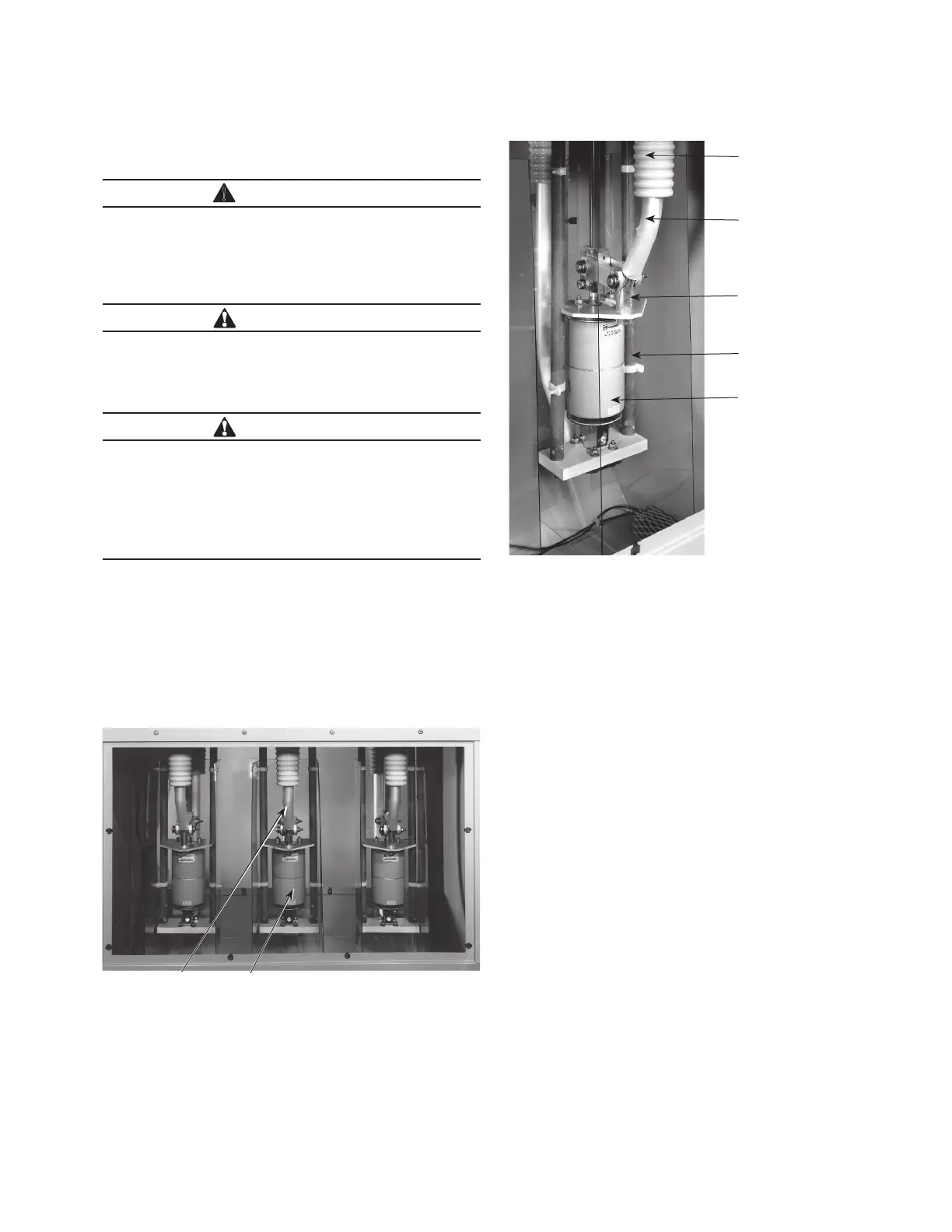

Figure 13. VSA20 vacuum interrupter assembly.

Recloser tripping and closing are initiated by signals from

the recloser control unit. When current in excess of the

programmed minimum trip level is detected on any phase

or phases, the recloser control initiates a trip signal which

energizes a solenoid in the operating mechanism of the

recloser. When actuated, this solenoid trips the opening

springs which opens the interrupter contacts.

Closing springs provide the force required to close the

vacuum interrupters as well as the force required to charge

the opening springs. A 240 Vac motor charges the closing

springs through a multi-stage gear drive. When 240 Vac is

present, the motor is automatically operated to keep the

closing springs in a charged state.

To close the recloser, the control initiates a signal which

energizes a solenoid in the recloser operating mechanism.

Once actuated, the solenoid releases the closing springs,

closing the vacuum interrupters. At the same time, the

opening springs are charged and, when 240 Vac is present,

the closing springs are charged. An external 240 Vac source

is required to operate the drive motor.

Recloser tripping employs stored spring energy. The 240

Vdc supply is not required to trip the recloser. When the trip

solenoid is actuated by the 24 Vdc trip signal, the stored

spring energy is released to open the recloser. The 24 Vdc

trip signal is originated at the recloser control.

Bushing Lead

Vacuum Interupter

Bushing

Bushing Lead

Current Exchange Assembly

Support Stringer

Vacuum Interrupter

Loading...

Loading...