Page 52 (60) Motor Pump Enhanced Protection Application SV9000

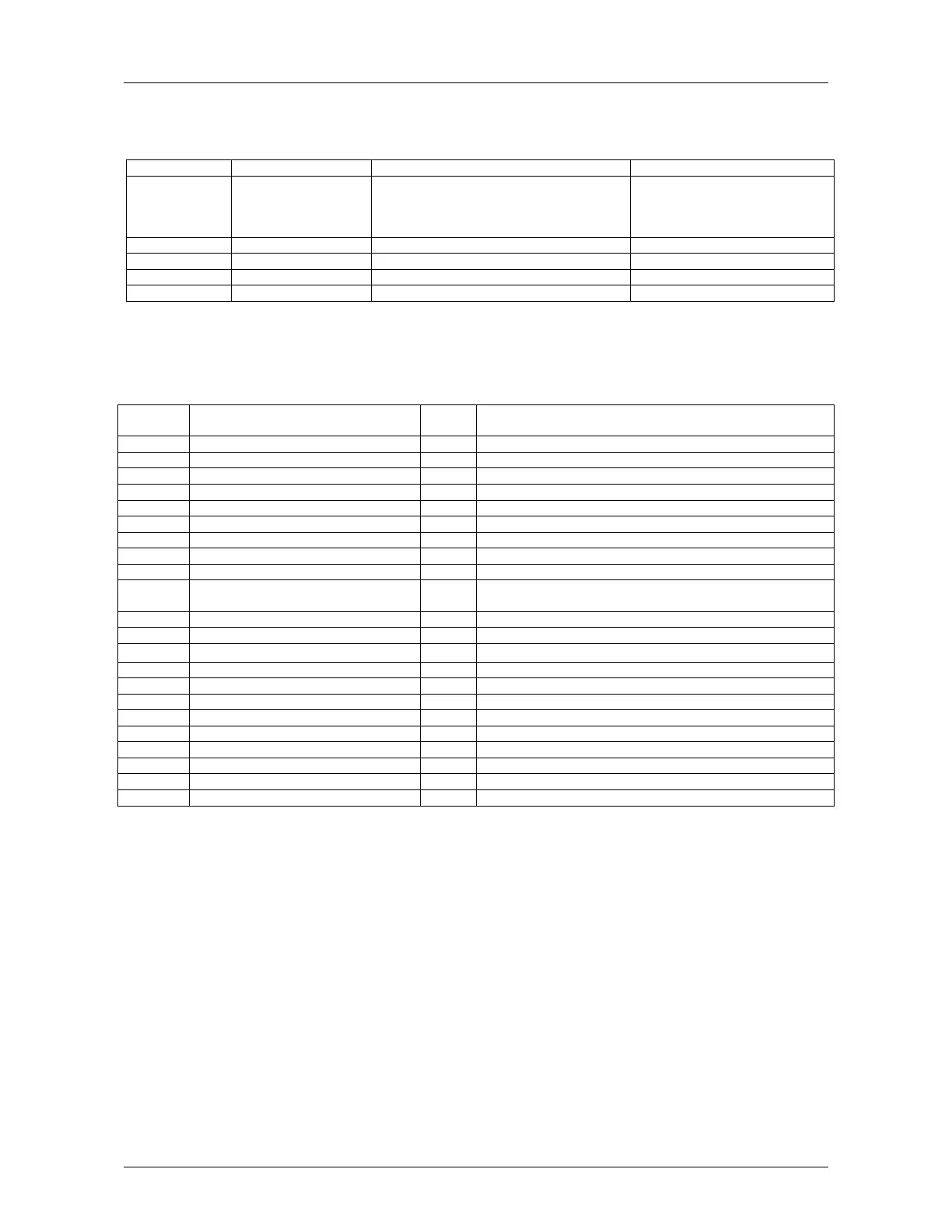

7 Fault Code

The Motor Pump Enhanced Protection application has some extra fault codes:

Fault Number Fault Possible Cause Check

27 Fieldbus

communication error

Fieldbus board has detected the reset of

error of the Bus system (physical layer)

Reset the fault and restart

again. If the fault comes again:

- check the host system

– check the cables

50 Hot Motor Winding I/O detected a fault at this input Verify settings in group 11

51 Hot Motor Bearing I/O detected a fault at this input Verify settings in group 11

52 Seal Leak Detection I/O detected a fault at this input Verify settings in group 11

53 High Vibration I/O detected a fault at this input Verify settings in group 11

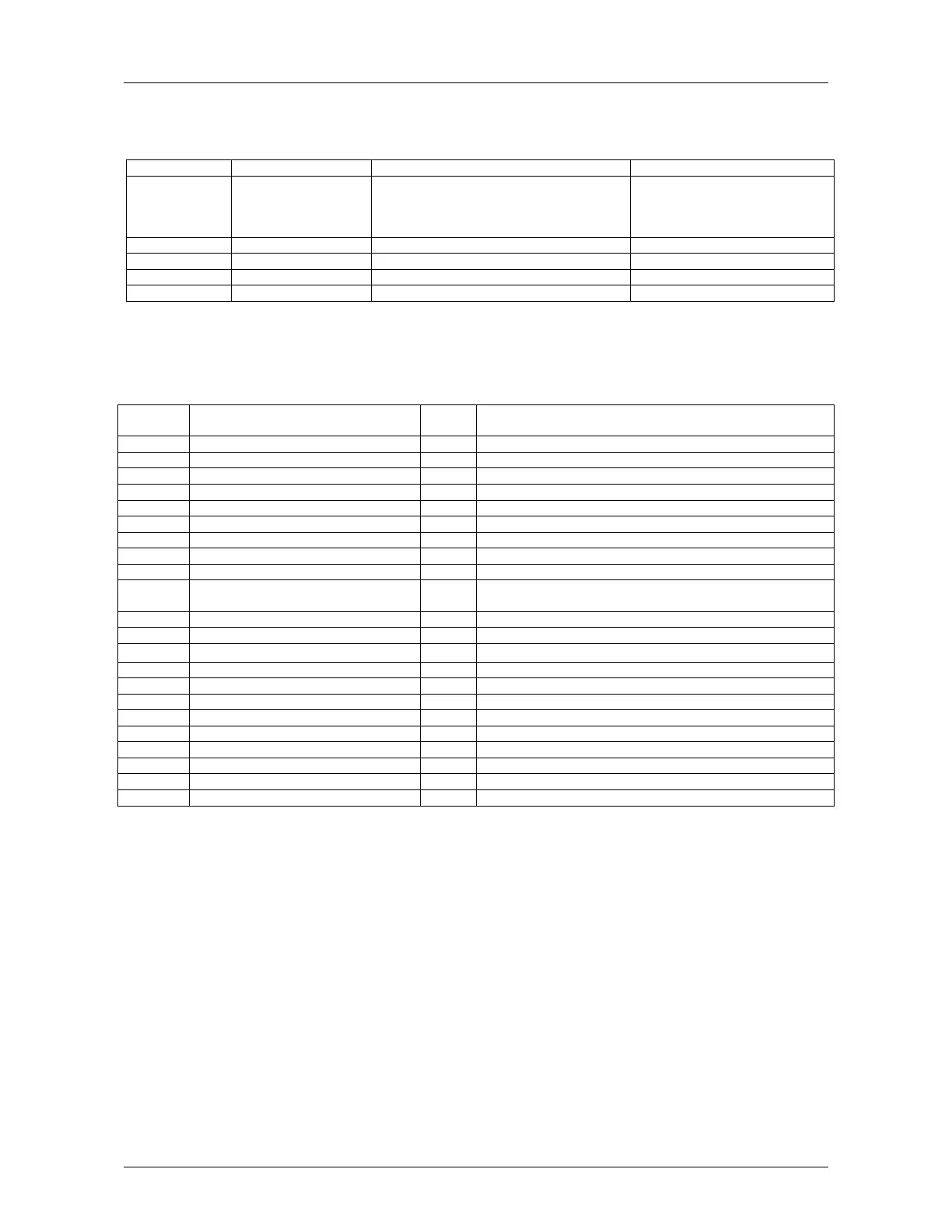

8 Monitoring Data

The Multipurpose Application II has extra items for monitoring (n21 - n22). See table 8-1.

Data

Number

Data Name Unit Description

V1 Output frequency Hz Frequency to the motor

V2 Motor speed rpm Calculated motor speed

V3 Motor current A Measured motor current

V4 Motor torque % Calculated actual torque/nominal torque of the unit

V5 Motor power % Calculated actual power/nominal power of the unit

V6 Motor voltage V Calculated motor voltage

V7 DC-link voltage V Measured DC-link voltage

V8 Temperature °C Temperature of the heat sink

V9 Operating day counter DD.dd Operating days

1)

, not resettable

V10 Operating hours "trip counter" HH.hh Operating hours

2)

, can be reset with programmable

button #3

V11 MW-hours MWh Total MW-hours, not resettable

V12 MW-hours, "trip counter" MWh MW-hours, can be reset with programmable button #4

V13 Voltage/analog input V Voltage of the terminal V

in

+ (term. #2)

V14 Current/analog input mA Current of terminals I

in

+ and I

in

- (term. #4, #5)

V15 Digital input status, gr. A

V16 Digital input status, gr. B

V17 Digital and relay output status

V18 Control program Version number of the control software

V19 Unit nominal power HP Shows the power size of the unit

V20 Motor temperature rise % 100%= temperature of motor has risen to nominal

V21 Reference frequency Hz Frequency reference

V22 Torque reference % Torque reference when torque control in use

1)

DD = full days, dd = decimal part of a day

2)

HH = full hours, hh = decimal part of an hour

Table 8-1 Monitoring items

Loading...

Loading...