Loading...

Loading...

Do you have a question about the EFI VUTEk 5r Series and is the answer not in the manual?

| Print Resolution | Up to 1200 dpi |

|---|---|

| Media Types | Vinyl |

| Ink Configuration | White |

| Media Handling | Roll-to-roll |

| Connectivity | Ethernet |

| Print Technology | Piezo Drop-on-Demand Inkjet |

Welcome message and overview of the guide's purpose and scope.

Information on required training and documents before starting maintenance procedures.

Details on warnings, cautions, and notes for safe operation and maintenance.

Instructions for using retaining pins to prevent the printer hood from closing during maintenance.

Information about available maintenance videos for user review prior to procedures.

Contact details for customer care, technical support, and ordering parts by region.

Guidelines for efficient maintenance routines and preparation before starting tasks.

Details on using the Printer Maintenance Log to track completed tasks and its importance.

Warning regarding powerful magnets in the printer beam and precautions for medical devices.

Instructions for handling fluid emergencies and accessing Safety Data Sheets (SDS).

First aid procedures for eye contact, ingestion, skin contact, and inhalation of inks/solvents.

Benefits of routine maintenance for printer reliability, print quality, and productivity.

Explanation of maintenance guidelines based on an eight-hour production schedule.

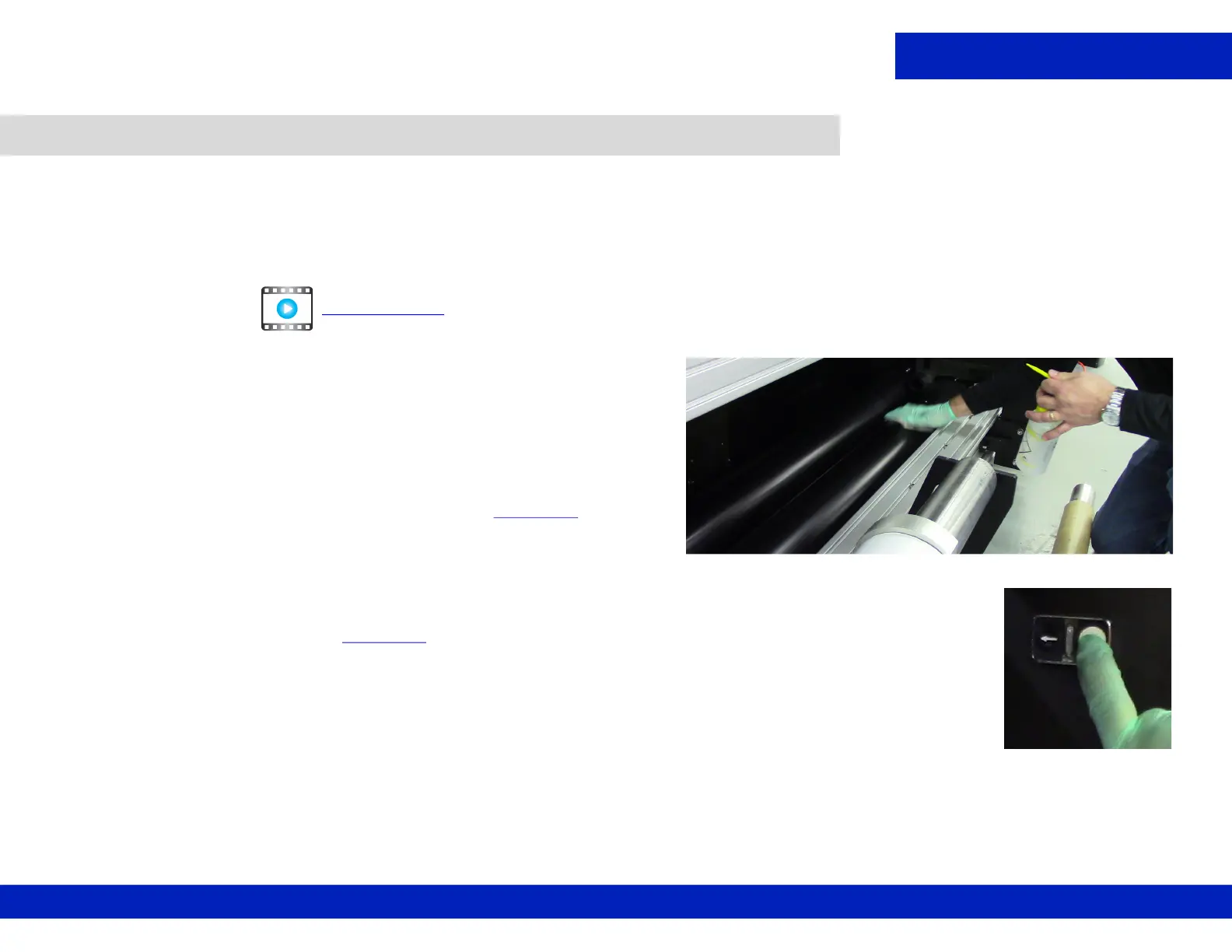

Procedure to clean the area around the print heads and the bottom of the carriage.

Steps for cleaning the print heads, including purging and wiping procedures.

Instructions for cleaning the underside of various carriage components using IPA.

Procedure to check facility air compressor and filter systems for proper air quality.

Steps for cleaning the print platen surface using IPA and a scraper.

Instructions for cleaning the underside of the measure media sensor.

Procedure for cleaning the ink sink to remove ink deposits.

Steps to expose and clean the LED lamp glass.

Procedure for cleaning the underside of the ionizer bars.

Instructions for cleaning the left and right carriage crash sensors.

Steps for performing print head care, including wiping and purging.

Procedure for white ink maintenance, including purging and stirring.

Steps for cleaning the free-fall rollers using roll conditioning fluid.

Procedure for cleaning the T (Tension) rubber roller.

Steps for cleaning the Y (Shaft) rubber roller.

Procedure for cleaning input feed, press, and collector rollers.

Instructions for lubricating the carriage bearings using a grease gun.

Procedure for checking and emptying the waste container.

Steps for cleaning the ends of the carriage rails.

Procedure for checking and filling the chiller fluid level with distilled water.

Instructions for checking and draining water/oil from pneumatic filters.

Procedure for cleaning the printer's exterior covers and ventilation areas.

Steps for vacuuming the lower and upper cable carrier shelves.

Procedure for cleaning the three main exhaust vents, including removing housing and vacuuming fan.

Instructions for cleaning the linear encoder strip.

Procedure for cleaning the carriage home sensor using a foam swab.

Steps for inspecting and replacing white ink degasser tubes.

Instructions on how to export and create a backup of printer settings and status.

Procedure for replacing the primary ink filters.