INSTALLATION INSTRUCTIONS | SMART LINE BOILING PAN

EN | 10-2018 DOC N° ST0 9183-02 31

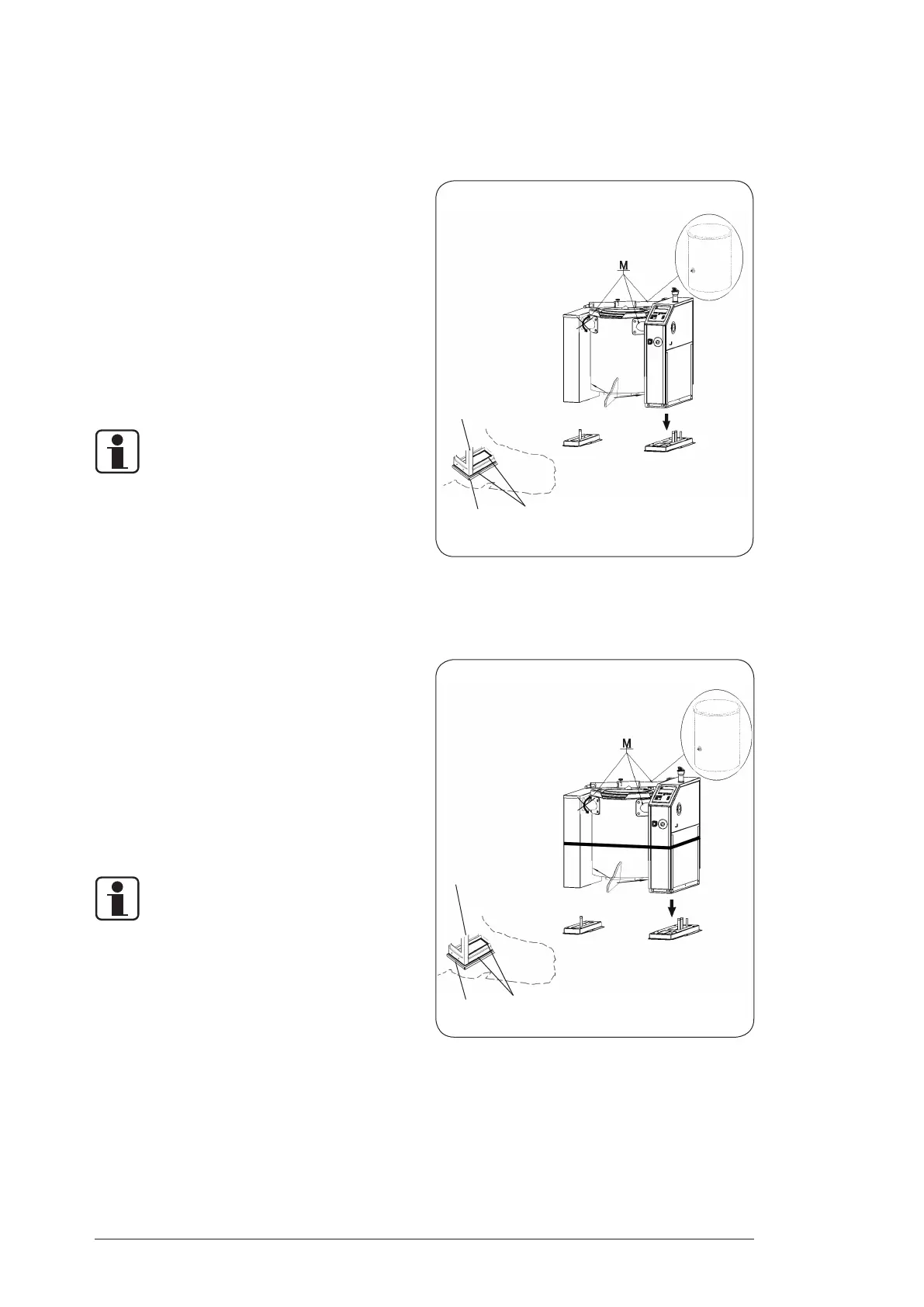

14. POSITIONING OF BOILING PANS IN THE FIELD

1. Dismantle right columns front, side plate

and rear.

2. Disconnect the transport protection from

the support leg.

3. Remove the right column from the bottom of

the packaging.

4. Disconnect the vessels transport leg.

5. Lift the pan at the appropriate lifting points

(e.g. the shaft between vessel and column

and at the vessel’s transport leg M.

NOTE

Please follow these instructions

• The centre of gravity is pushed forwards. For

supplementary weight data, see chapter “2.

Models”

6. Take care with the cables and the front of

the right column when dismantling and

transporting.

7. Lift the pan into position.

8. Screw the right column and the left column

onto the wall or mounting frames.

9. Lift the next pan into place and screw in.

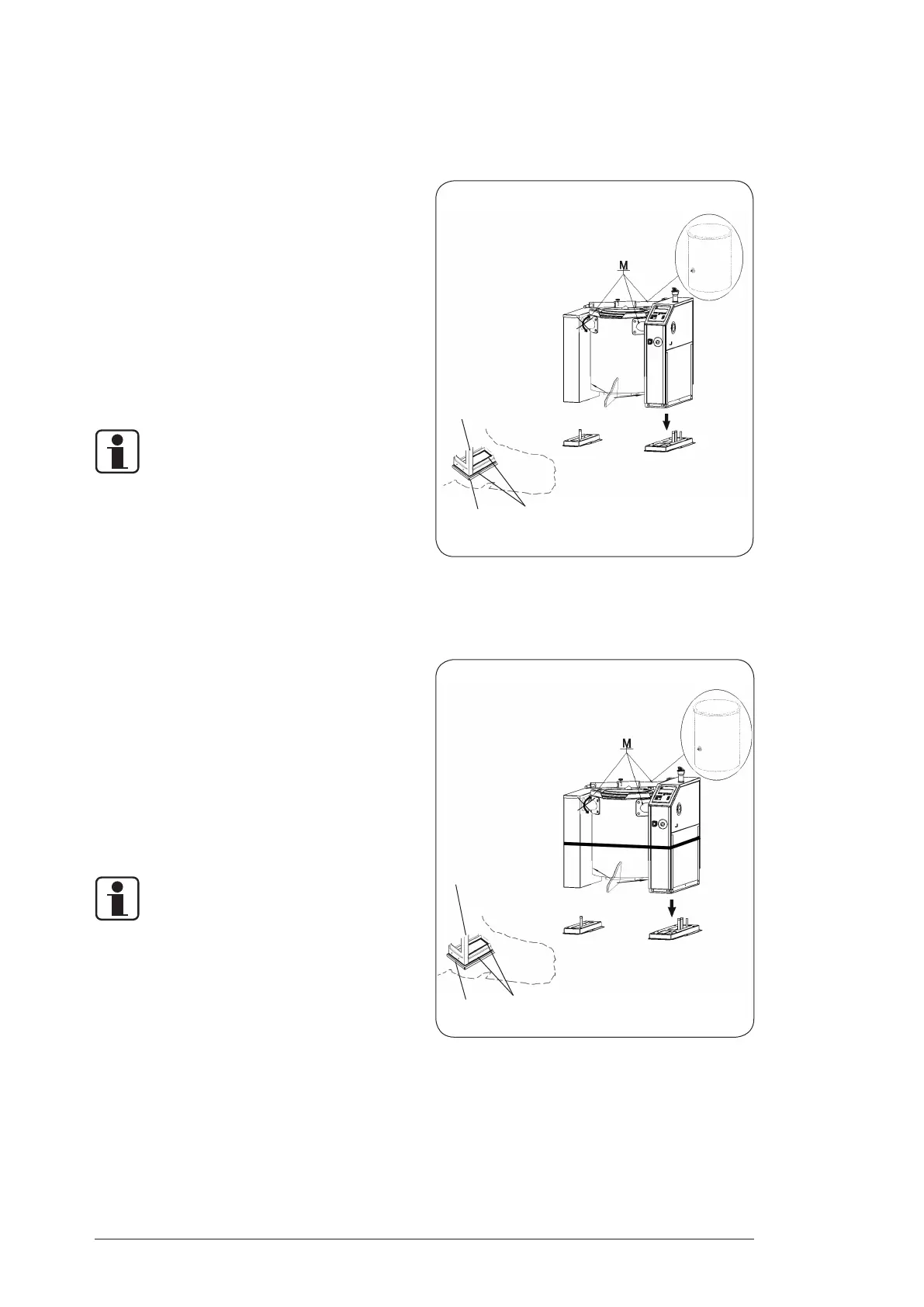

10. Connect the electrical cables and check

that the tip motor is running in the right

direction.

11. Connect the cold and hot water lines.

NOTE

Please follow these instructions

• If the pan has a flow meter, the maximum flow

will be 45 l/minute.

• Incoming water lines are supplied with shut-

off valves, which are installed at the bottom of

the column as close to the floor as possible;

these are not supplied.

• Ensure that there is a tight fir between the

column and the wall or mounting frame. Seal

with soft compound, for example, on the in-

side of the column facing the frame. If neces-

sary, the outside of the column can also be

sealed to the frame.

14.1 Models: SM6B, SM6V, SM6P

14.2 Models: Boiling pan

with the option ice water cooling

SV6I, SP6I

Column

Frame Sealing compound

Column

Frame Sealing compound

Fig. 19

Fig. 20

Loading...

Loading...