31

Reference Manual

00809-0100-4853, Rev AB

Installation

January 2017

Installation

Figure 3-15. Rosemount 305 Manifold Styles

The Rosemount 304 comes in two basic styles: traditional (flange x flange and flange x pipe) and wafer.

The traditional manifold comes in 2-, 3-, and 5-valve configurations. The wafer manifold comes in three-

and five-valve configurations.

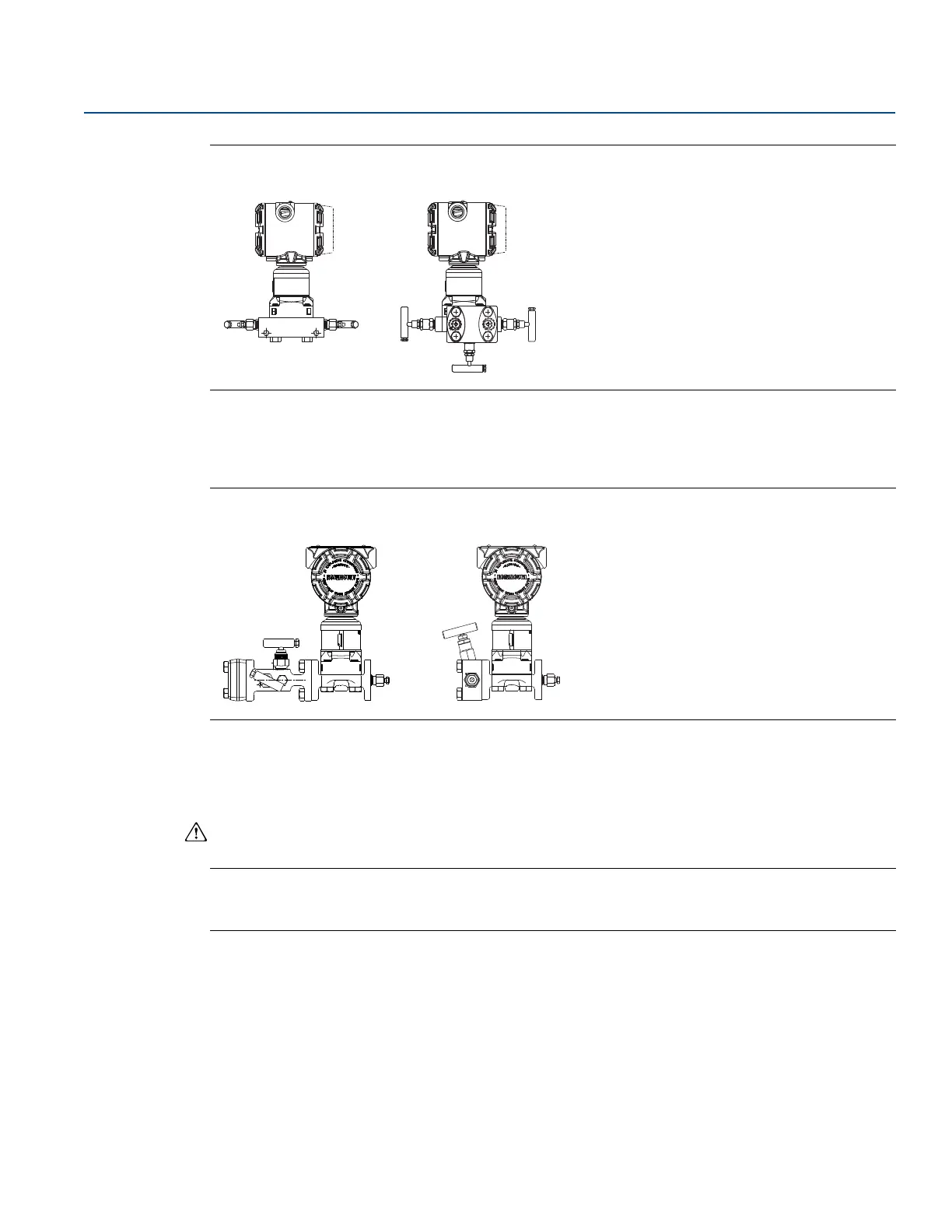

Figure 3-16. Rosemount 304 Manifold Styles

3.5.1 Rosemount 305 Integral Manifold installation procedure

To install a Rosemount 305 Integral Manifold to a Rosemount 3051SMV:

1. Inspect the PTFE SuperModule

™

O-rings. If the O-rings are undamaged, reusing them is

recommended. If the O-rings are damaged (e.g. nicks), replace them with new O-rings.

Note

If replacing the O-rings, be careful not to scratch or deface the O-ring grooves or the surface of the

isolating diaphragm when removing the damaged O-rings.

2. Install the Integral manifold on the SuperModule process connection. Use the four manifold bolts for

alignment. Finger tighten the bolts, then tighten the bolts incrementally in a cross pattern to final

torque value. See Table 3-1 on page 22 for complete bolt installation information and torque values.

When fully tightened, the bolts should extend through the top of the SuperModule housing.

3. If the PTFE SuperModule O-rings have been replaced, the flange bolts should be re-tightened after

installation to compensate for seating of the O-rings.

4. If applicable, install flange adapters on the process end of the manifold using the 1.5-in. flange bolts

supplied with the transmitter.

Integral coplanar Integral traditional

Traditional Wafer