Installation, Operation and Maintenance Manual

VA-DC-000-1803 Rev. 2

July 2020

29

Section 3: Actuator Reassembly

Actuator Reassembly

3.5.21 Install lock washers (7 - 95) onto tie bars (7 - 20) and up against outer end cap (7 - 80).

3.5.22 Install hex nuts (7 - 90) onto tie bars (7 - 20) and up against lock washers (7 - 95).

3.5.23 Torque tighten hex nuts (7 - 90) until a nal lubricated torque, as listed in the

following Table, has been achieved.

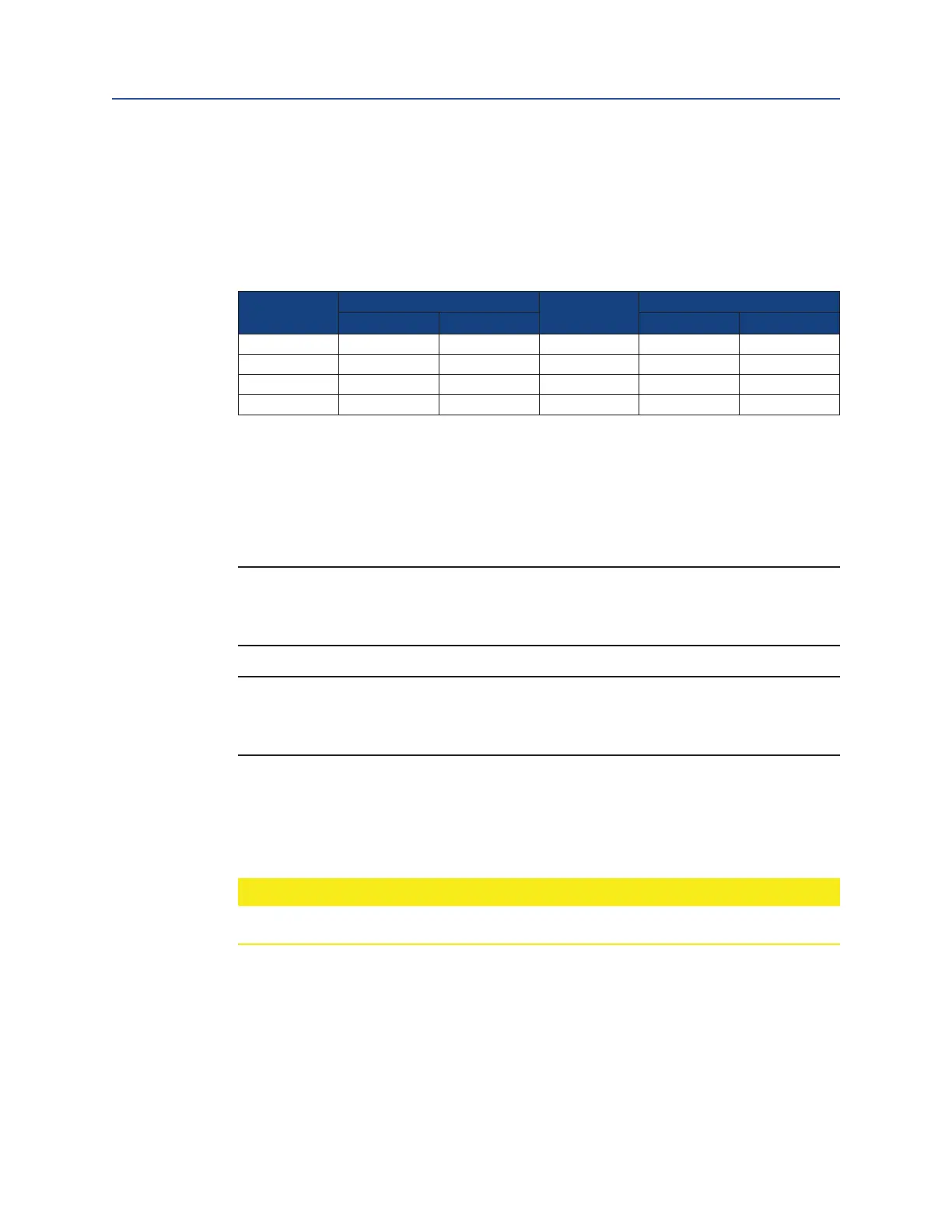

Table 5. Tie Bar Nuts (3 - 90)

Housing

Model

Torque (±5%)

Housing

Model

Torque (±5%)

lb-ft Nm lb-ft Nm

G01 70 95 G5 385 522

G2 70 95 G7 580 786

G3 70 95 G8 580 786

G4 135 183 G10 1,000 1,356

3.5.24 Torque tighten piston rod (3 - 40) per the chart in Section 5.4, step 5.4.5.

3.5.25 Install the M18 Hydraulic Override Cylinder per Section 5, step 5.4.

3.6 M18 Pump Reassembly

NOTE:

Review Section 3.1 General Reassembly before proceeding with the M18 Hydraulic

Override Cylinder Reassembly. Refer to VA-ED-005-1120 for details.

NOTE:

In Section 3.5 where the step indicates to "lubricate, coat or apply uid", use hydraulic uid,

as identied in Section 1, step 1.6.2, for lubricating the part being installed.

3.6.1 Lubricate pump cyl (20 - 10 - 20) inside diameter with hydraulic uid.

3.6.2 Install ppak (20 - 20 - 10), rod bushing (20 - 20 - 30) and rod wiper (20 - 20 - 20)

into the pump cyl (20 - 10 - 20).

!

CAUTION

Install Polypak seal correctly.

3.6.3 Install seal o-ring (20 - 20 - 60) and backup ring (20 - 20 - 70) into the pump

cyl (20 - 10 - 20).

3.6.4 Lubricate pin, cyl (20 - 10 - 60) with hydraulic uid.

3.6.5 Install backup ring (20 - 20 - 50) and seal O-ring (20 - 20 - 40) onto the pin,

cyl (20 - 10 - 60).

Loading...

Loading...