11

2.7.1 Check #1: Rotation on VFD power

Place the VFD package in HAND (local) control by pressing the VFD and

HAND push buttons of the Electronic bypass keypad. The VFD, HAND, input

and output contactor LEDs will be illuminated. The VFD must be started and

stopped by the start/stop buttons on the VFD keypad. Use the up arrow on the

VFD Keypad to increase the speed reference of the VFD or the down arrow on

the VFD Keypad to decrease the speed reference of the VFD. Note the

direction of rotation as the motor shaft begins to rotate as compared to the

required rotation direction.

To stop the VFD, press the OFF/RESET push button.

2.7.2 Check #2: Rotation on Bypass power

NOTE: This operation will start the motor across-the-line. Place the Electronic

bypass in the BYPASS mode by pressing the BYPASS pushbutton on the

Electronic bypass keypad. The BYPASS LED will light.

Press the HAND button on the Electronic bypass keypad. This will start the

motor across

the line. Check motor rotation.

Quickly stop the motor by pressing the OFF/RESET push button.

Note the direction of rotation as the motor shaft begins to rotate as compared

to the required rotation direction.

Change the appropriate leads as noted in the following table.

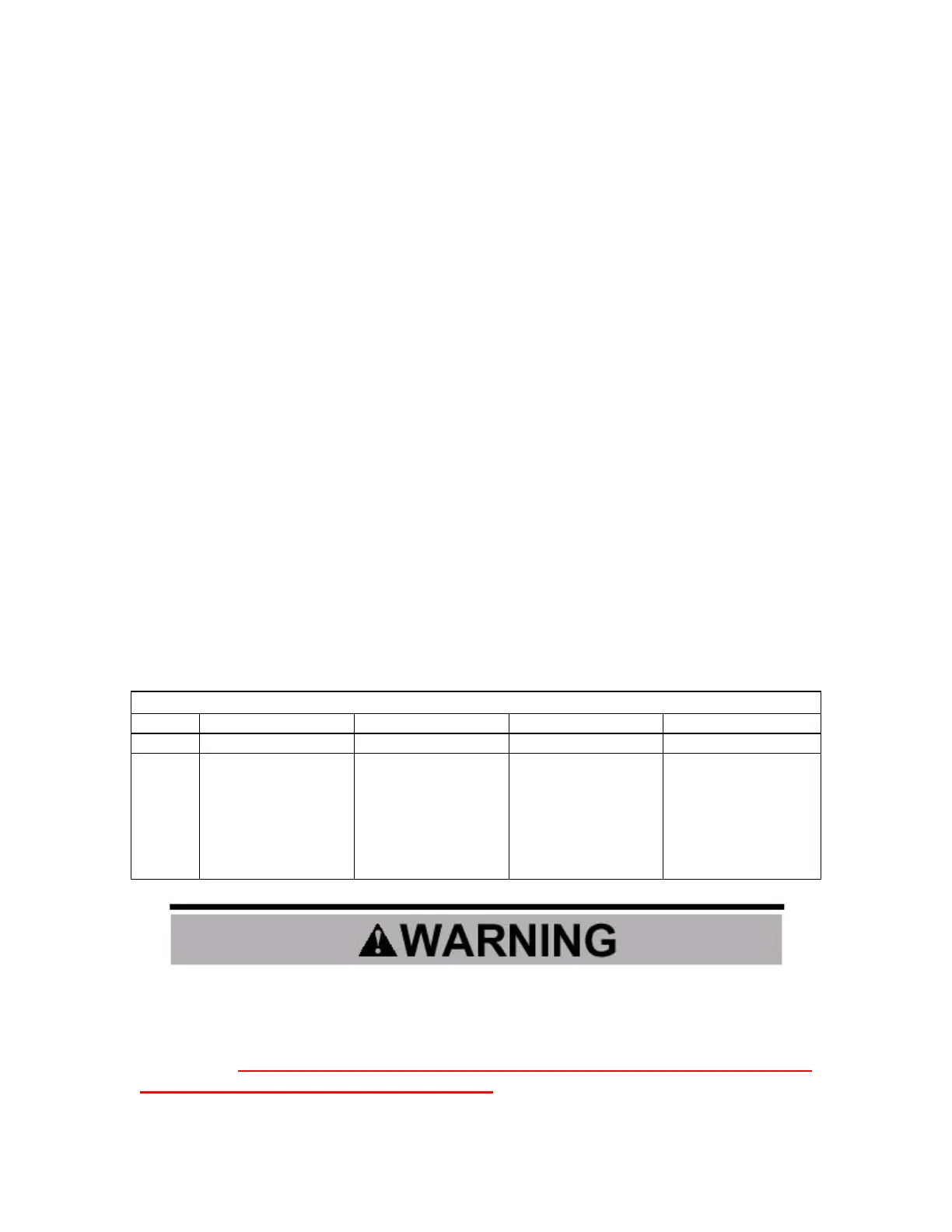

Motor Rotation Correction

VFD Correct Correct Incorrect Incorrect

Bypass Correct Incorrect Correct Incorrect

Action

No Action.

Change any two

power leads at input

disconnect.

Change any two

leads at input at

input disconnect,

and change any two

leads at the output

of the motor

overload.

Change any two

leads at output of

motor overload.

There is no standard for the rotational direction of an induction motor based

on the motor lead markings. This, plus the uncertainty of the phase rotation

of the utility power being applied to the Electronic bypass package

terminals, requires that the motor rotation direction be checked and be

correct in both VFD and Bypass modes. Failure to confirm rotation may cause

severe damage to the Electronic bypass package, motor or the driven equipment.

Loading...

Loading...