Installation

8.

310

· 274 ·

Ref.1912

DDS

HARDWARE

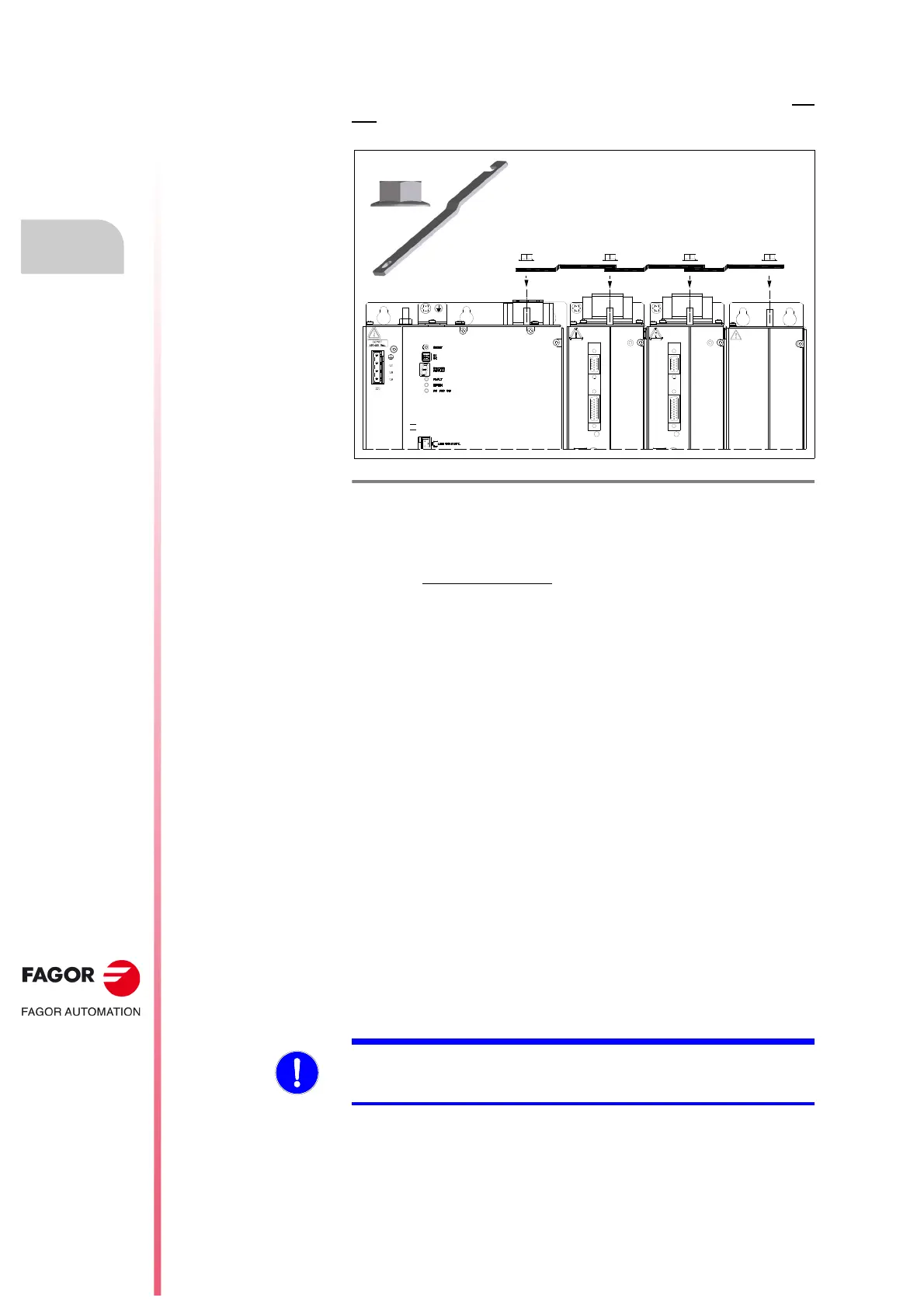

Joining the chassis between modules

The chassis of the modules must be connected to each other through the M6

bolt on top of each module. To do this, the irregular plate and the nut

supplied as accessories with each module must be used.

The tightening torque must be between 2.3

2.8 N·m.

Connecting these terminals by means of metal plates offers mechanical

rigidity; but it does not guarantee

proper ground connection of each module.

To replace a module in case of a failure or remove it from the DDS system

for inspection, follow these steps to “free” it from the other modules.

A. Loosen the screw and the nut of the affected module.

B. Loosen the nut of the adjacent module on each side that joins it to the

affected module.

C. Rotate the plate of the affected module and that of the one to its left, see

figure

F. H8/9 .

After these steps, the drive will be totally free from the rest of the modules

that were joined by the plate.

All the cables connecting it to the rest of the modules must also be removed.

Ground connection

The chassis of each modules must be connected to a single point and from

there to the ground terminal of the electrical cabinet. When applying a 10 A

current between this ground point and any of these points, the voltage drop

must not exceed 1 V. Use the nuts supplied with each module to make the

ground connection.

F. H8/9

Joining the chassis between modules. Include the BPM module only if

applicable.

RPS 45

X4

X3

UVW

DRIVE MODULE

X5

X6

X4

X3

UVW

DRIVE MODULE

X5

X6

OTECTION MODULE

MANDATORY. It is up to the system integrator to meet all the requirements

of local and national electrical codes as well as all the regulations applicable

regarding the grounding of the whole unit.

Loading...

Loading...