Instruction Manual

D103175X012

GX Valve and Actuator

July 2017

3

Personal injury or equipment damage caused by sudden release of pressure or bursting of pressure retaining parts might

result if service conditions exceed those for which the product was intended. To avoid injury or damage, provide a relief

valve for over pressure protection as required by government or accepted industry codes and good engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

CAUTION

This valve is intended for a specific range of pressures, temperatures and other application specifications. Applying

different pressure and temperatures to the valve could result in parts damage, malfunction of the control valve or loss of

control of the process. Do not expose this product to service conditions or variables other than those for which the product was

intended. If you are not sure what these conditions are you should contact your Emerson sales office

or Local Business

Partner for more complete specifications. Provide the product serial number (shown on the nameplate, figure 2) and all

other pertinent information.

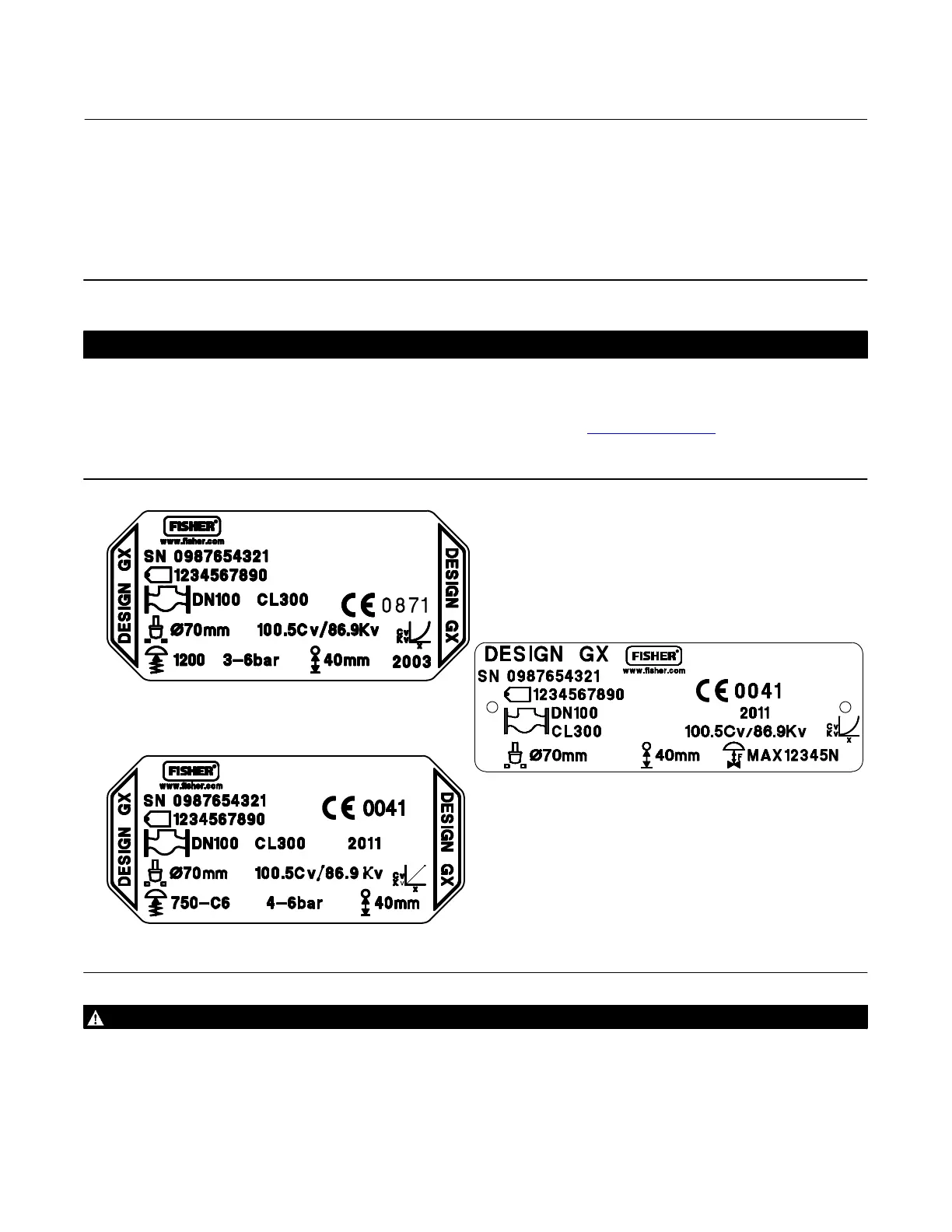

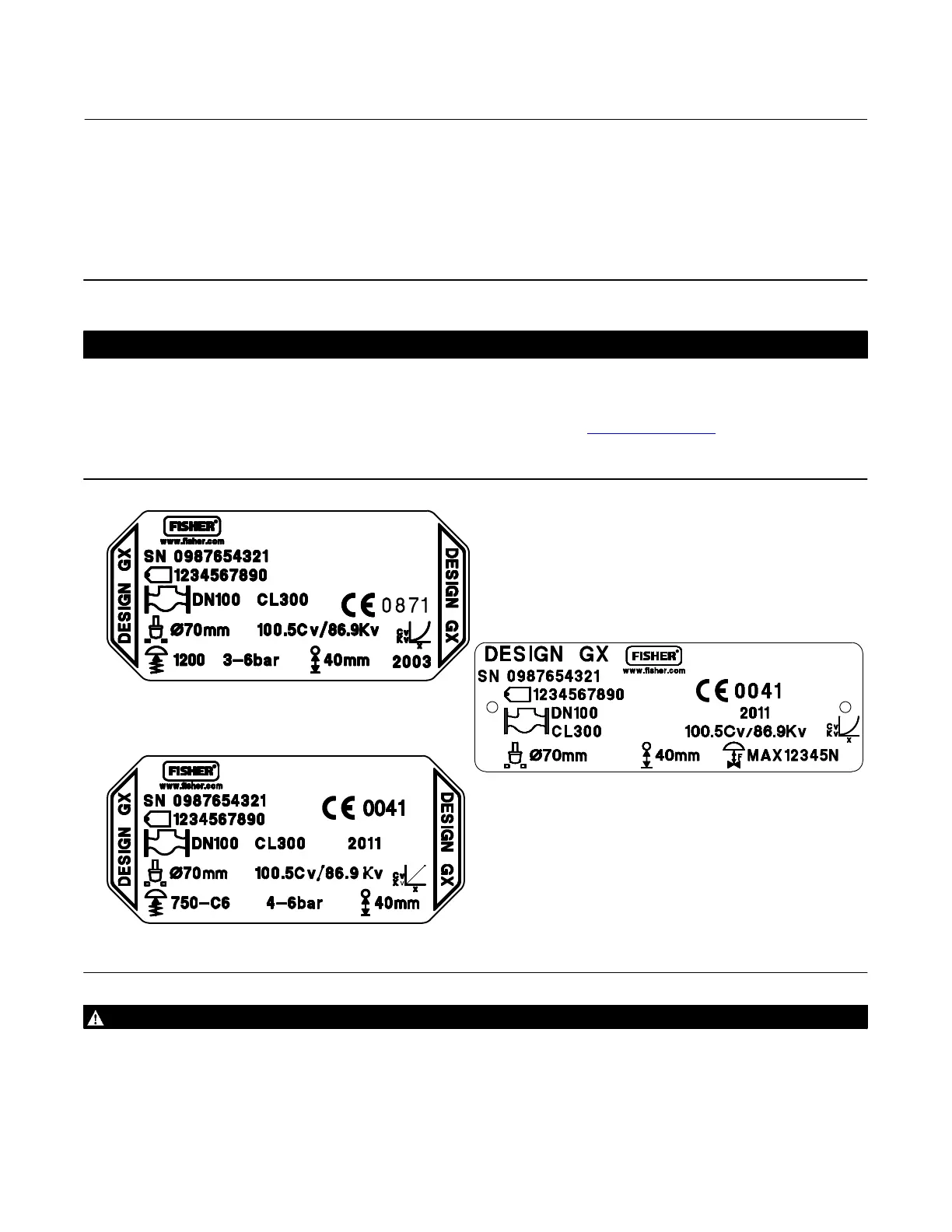

Figure 2. Fisher GX Nameplate Examples (Key 35)

GE41229-Sheet 1

WITH SPRING INFORMATION

WITHOUT SPRING INFORMATION

(USED PRIOR TO 2009)

GE01296‐H

ELECTRIC ACTUATOR

GG12198-A

WARNING

If you move or work on an actuator installed on a valve with loading pressure applied, keep your hands and tools away from

the stem travel path to avoid personal injury. Be especially careful when removing the stem connector to release all loading

on the actuator stem whether it be from air pressure on the diaphragm or compression in the actuator springs. Likewise

take similar care when adjusting or removing any optional travel stop. Refer to the relevant actuator Maintenance

Instructions.

Loading...

Loading...