9

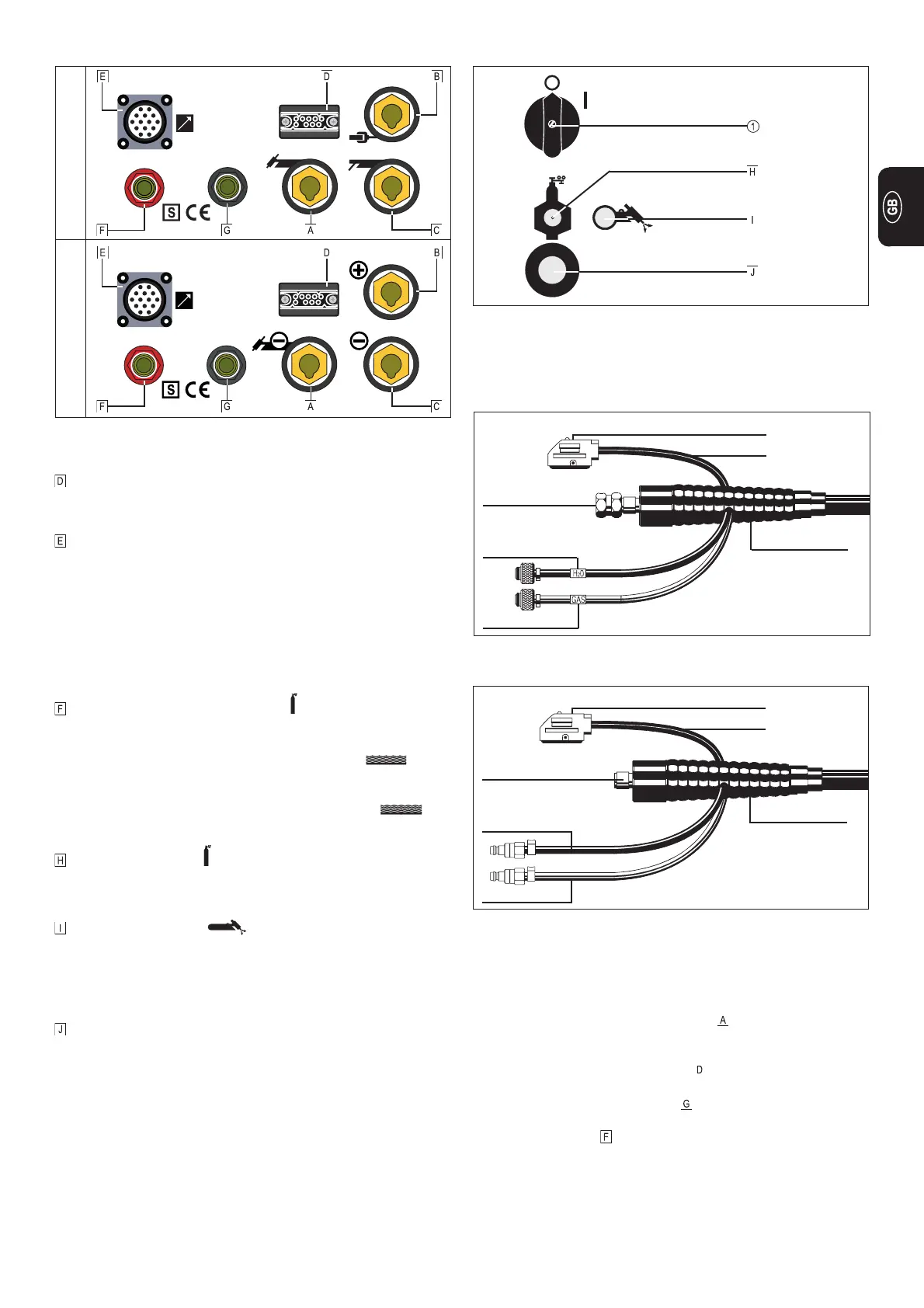

TORCH CONTROL SOCKET

- Plug in the control plug for the welding torch, and latch in

place.

CONNECTING SOCKET for remote control unit

- Plug the remote control cable plug into the socket, the right

way round, and tighten the swivel nut

- The desired welding current is set on the remote control unit.

- The machine automatically recognizes the fact that the

remote control unit has been plugged in

- The short-circuit-proof supply voltage to the remote control

units protects the electronics in the event of any damage to

the remote control cable.

GAS CONNECTION FOR TORCH

- for welding torch central connection GWZ

CONNECTION FOR WATER RETURN-FLOW

- for Fronius welding torch central connection F

CONNECTION FOR WATER FORWARD-FLOW

- Only on water-cooled machines

GAS CONNECTION

- Screw the terminal nut of the gas hose onto the connection-

fitting and tighten it

GAS TEST BUTTON

- For testing and adjusting the gas flow-rate with the current

switched off

- For setting the required gas flow-rate on the pressure

regulator

MAINS CABLE WITH STRAIN-RELIEF GRIP

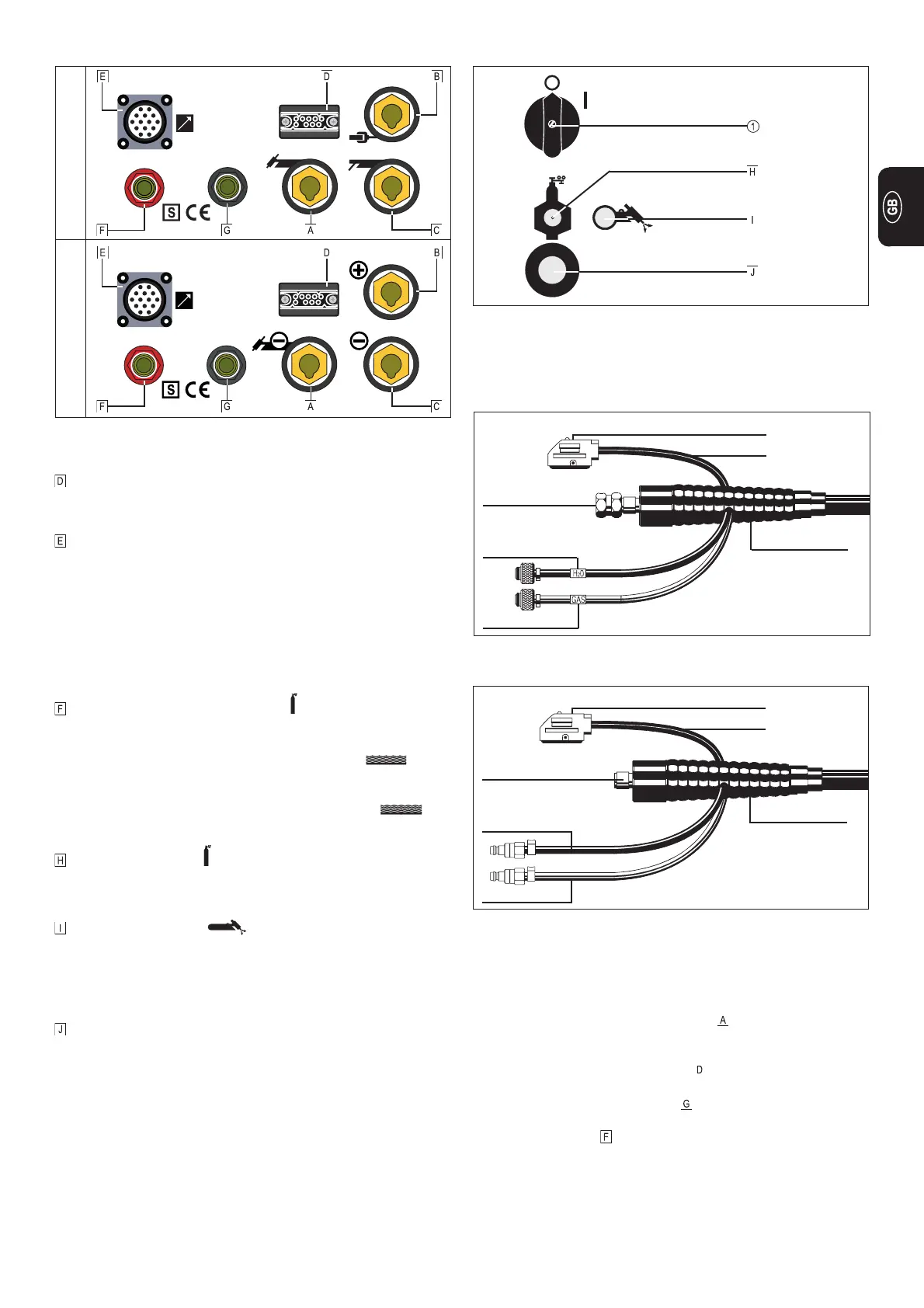

Gas hose

Water flow

Control cable

Fig.10 Design with central welding torch connection GWZ: Torch connection

water-cooled

Control plug

Hose sleeve

ASSEMBLING A WATER-COOLED TIG TORCH

Water and current

connection

Design with central burner connection GWZ:

- Pull back the tubular rubber sleeve of the torch

- Screw the hexagon nut (width 21, current and water connec-

tion) to the torch connection-fitting on the machine, and

tighten it.

- Push the rubber sleeve back over the hex nut

- Plug the control plug into socket and secure it

- Screw the knurled nut of the water connection onto the water

forward-flow connection-fitting , and tighten it

- Screw the knurled nut of the gas connection onto the gas

connection-fitting , and tighten it

Important! Please see your torch’s instruction manual for techni-

cal details on the torch and for information on torch assembly, care

and maintenance.

Fig.8a Design with Fronius central welding-torch connection F: Connection

points on front of machine

TRANSTIG MAGIC WAVE

Fig.9 Rear side of the machine

Fig.10a Design with Fronius welding torch central connection F: Torch connection

water-cooled

Gas and current

connection

Water connection

Water connection

Control cable

Control plug

Hose sleeve

Loading...

Loading...