10

COOLING UNIT FK 2600 / 2601

Important! Please see your operating instructions FK 2600 / 2601

(article no.: 42,0410,0490) for information on MOUNTING and

START-UP.

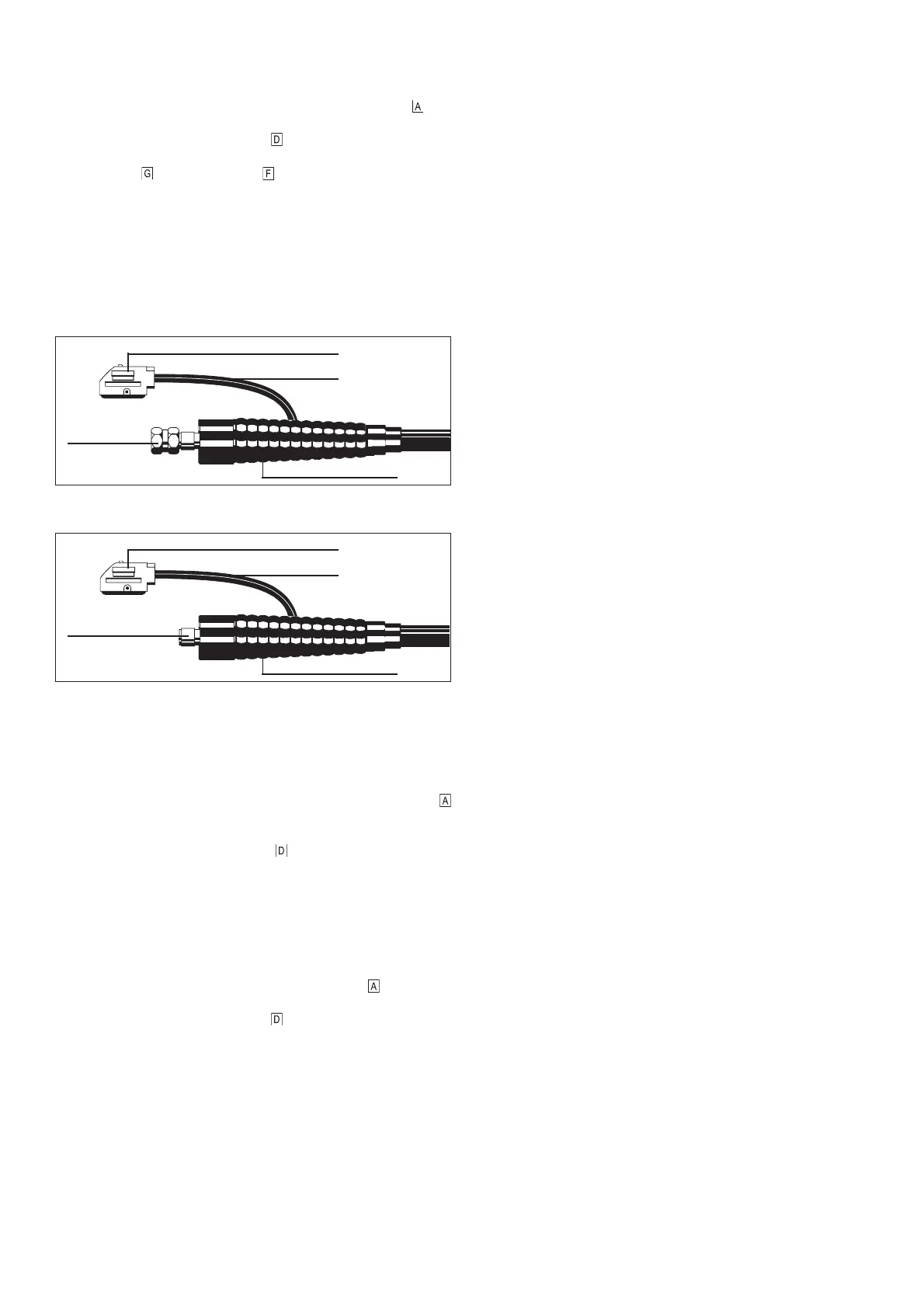

Fig.10b Design with central burner connection GWZ: Torch connection gas-

cooled

Design with central burner connection GWZ:

- Mount the gas adapter (44,0001,0785)

- Pull back the rubber sleeve from the rear of the torch

- Screw the hexagon nut (width across = 21) of the gas+current

connection onto the torch connector point on the machine

and tighten firmly

- Push the rubber sleeve back over the hexagon nut

- Plug the control plug into socket

and latch it

Important! Please see your torch’s instruction manual for techni-

cal details on the torch and for information on torch assembly, care

and maintenance.

Design with Fronius central welding torch connection F:

- Insert welding torch bayonet connection in the central connec-

tion on the equipment side of the welding torch

and lock in

place by turning to the right

- Insert control plug in the socket and lock in place

Important! Please see your torch’s instruction manual for techni-

cal details on the torch and for information on torch assembly, care

and maintenance.

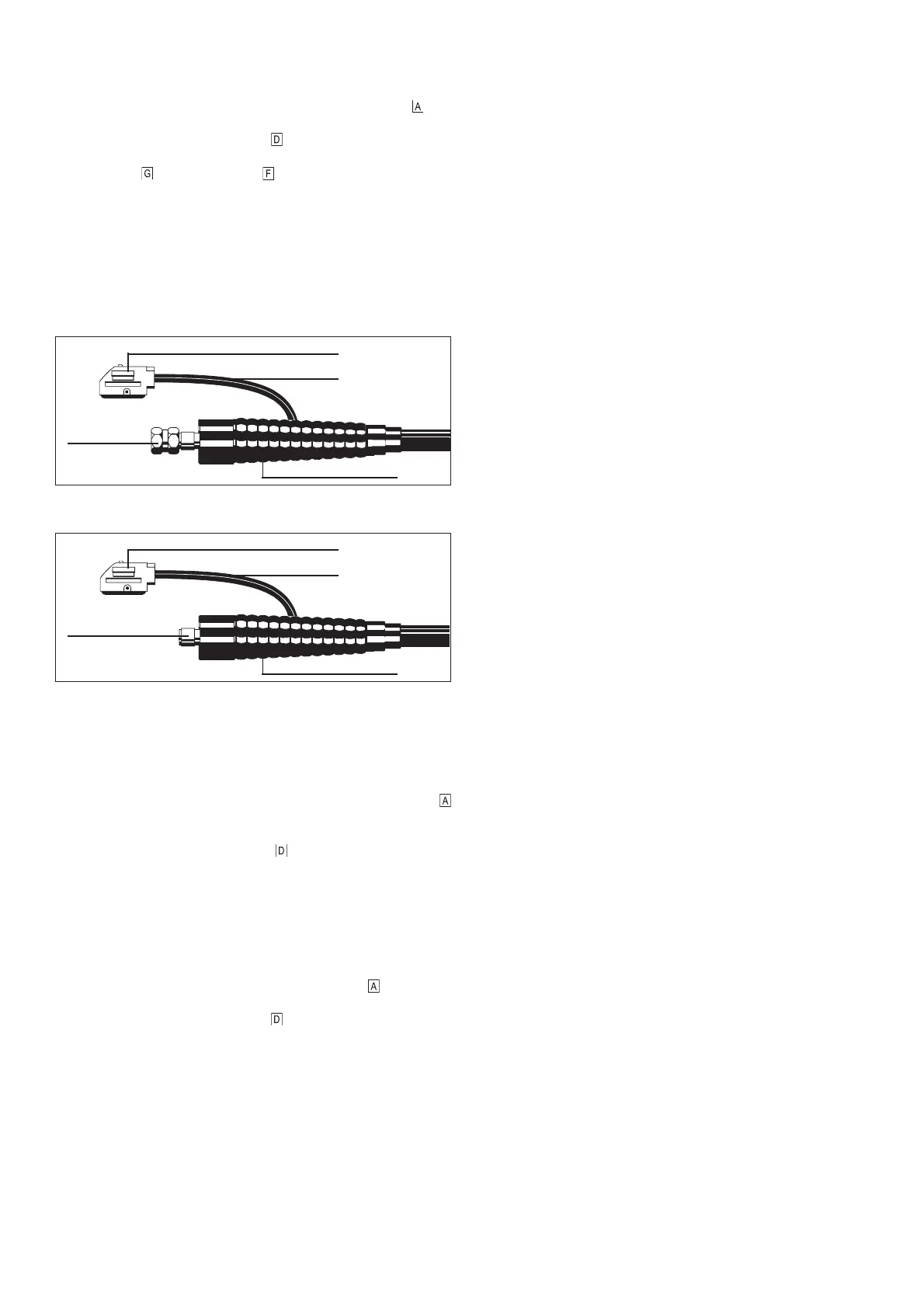

Fig.10c Design with Fronius central welding torch connection F: Torch connection

gas-cooled

Design with Fronius welding torch central connection F:

- Insert welding torch with bayonet connection into the central

connection on the equipment side of the welding torch

and

lock in place by turning to the right

- Insert control plug in the socket

and lock

- Connect water connections to the connection pieces on the

water feed and water return

Important! Please see your torch’s instruction manual for techni-

cal details on the torch and for information on torch assembly, care

and maintenance.

ASSEMBLING A GAS-COOLED TIG TORCH

Gas and current

connection

Control plug

Control lead

Hose sleeve

Gas and current

connection

Control plug

Control lead

Hose sleeve

Loading...

Loading...