Garmin G5 Electronic Flight Instrument Part 23 AML STC Maintenance Manual 190-01112-11

Rev. 7

Page 11 of 54

4.3 Electrical Bonding Test

LRU electrical bonding must be checked every 2,000 flight hours or 10 years, whichever occurs first.

4.3.1 Requirements

• Disconnect any cables and connectors normally attached to the LRU.

• Resistance must be measured from a bare metal portion of the LRU (chassis or connector) to an

airframe grounding location.

• The airframe grounding location should be as close to the LRU as possible, unless otherwise

noted in Table 4-2.

4.3.2 Test Equipment

Calibrated 4 wire Milliohm meter and Kelvin probes are required for this test.

4.3.3 Electrical Bonding Test Procedures.

• Using a calibrated milliohm meter and Kelvin probes measure the resistance of each LRU

between the locations noted in

•

• Table 4-2, and record the result of each installed LRU. Some equipment on the list are optional

and may not be installed.

• Ensure the resistance does not exceed 10 milliohms except for the GTP that shall be less than 2.5

milliohms.

• If the measured resistance is greater 10 milliohms, bonding must be improved to meet applicable

requirements for a new installation in accordance with Section 4 of Garmin G5 Electronic Flight

Instrument Part 23 AML STC Installation Manual (190-01112-10).

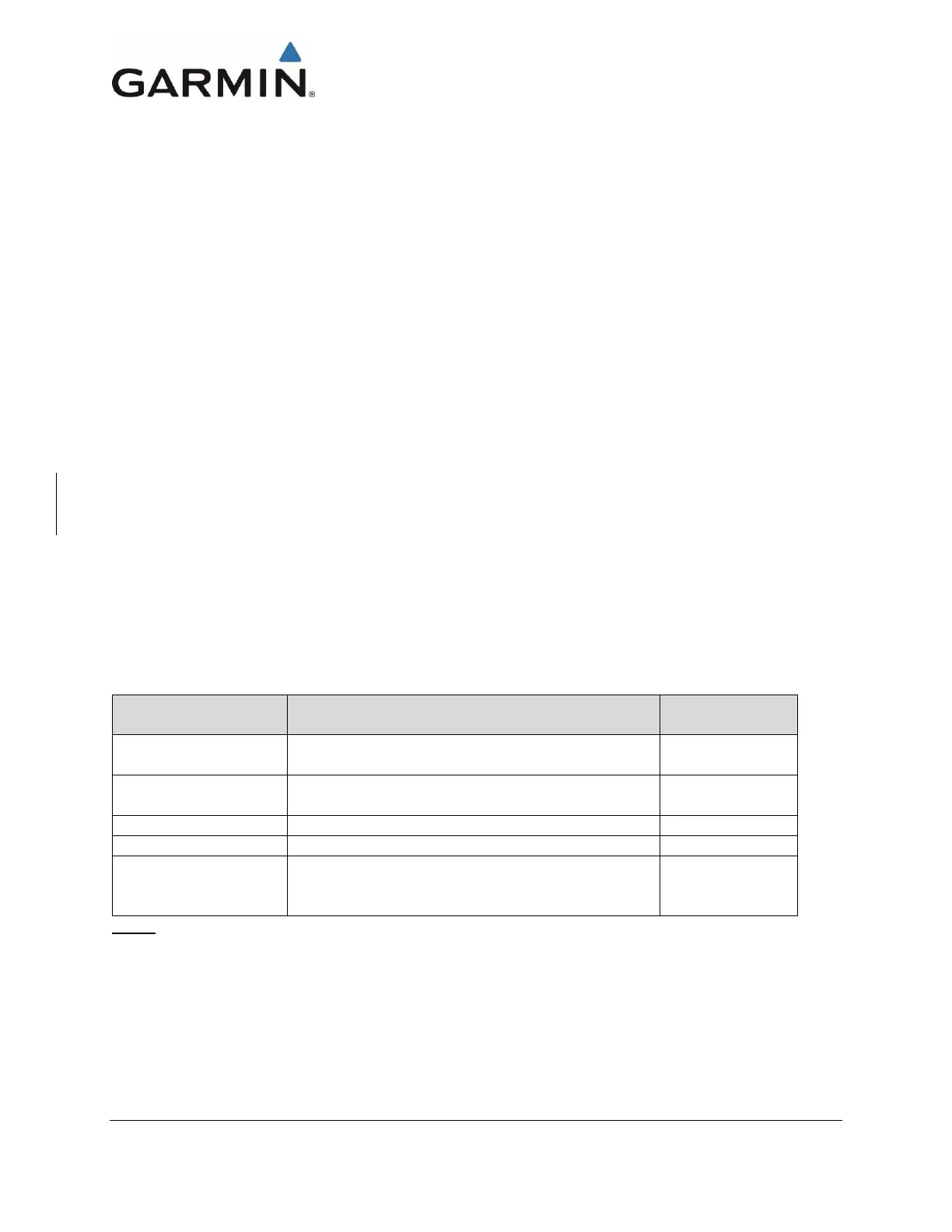

Table 4-2 – Electrical Bonding Procedure

Probe and adjacent local metal structure for metal

and tube and fabric aircraft.

For composite aircraft no bonding requirement

Notes:

(1) This is the ground stud to which the LRU bonding strap is connected

(2) For remote LRUs bonded to the back of the instrument panel via an installed aluminum foil ground plane,

the bonding measurement must be taken between the remote LRU and the instrument panel.

Loading...

Loading...