Section 19 - Self Test

39

19. Self Test

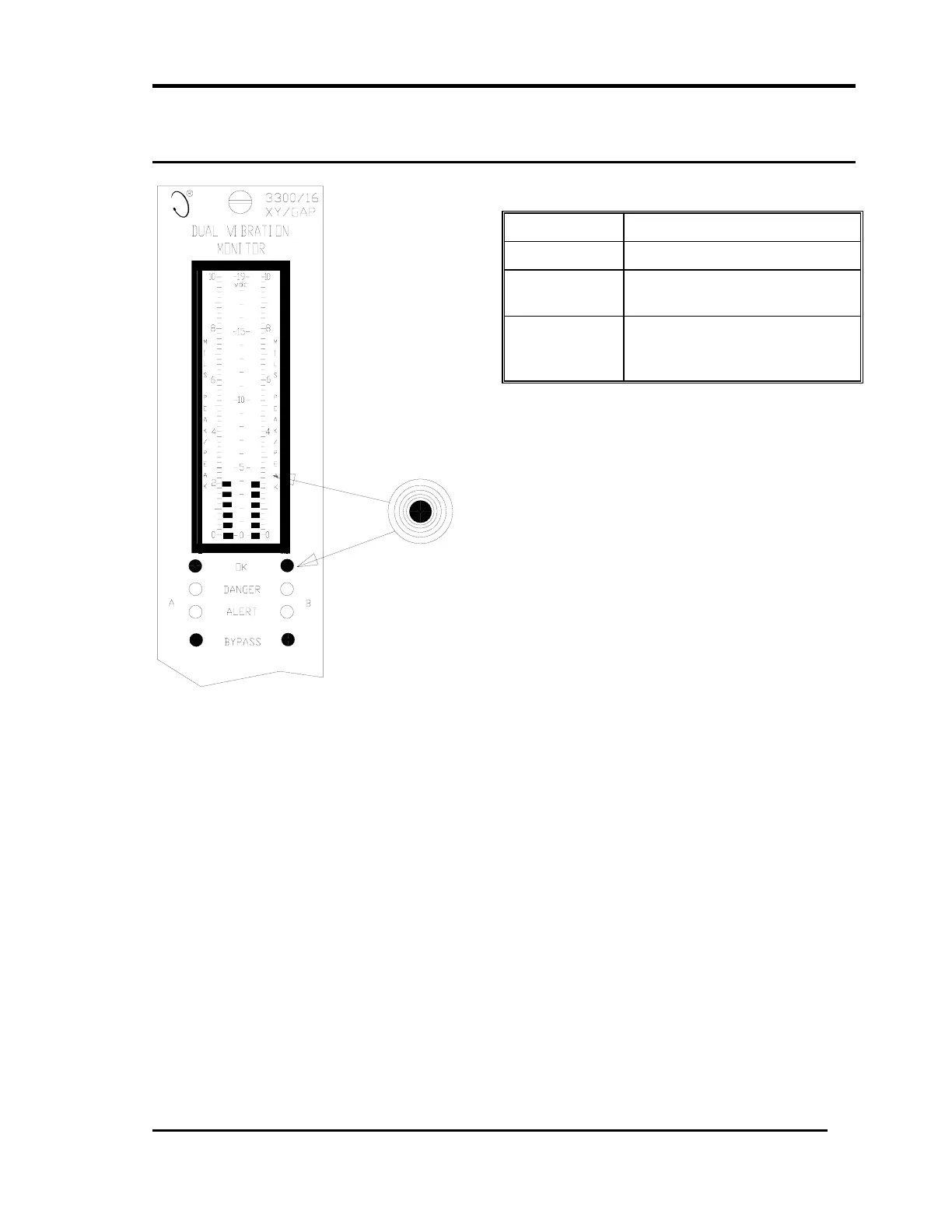

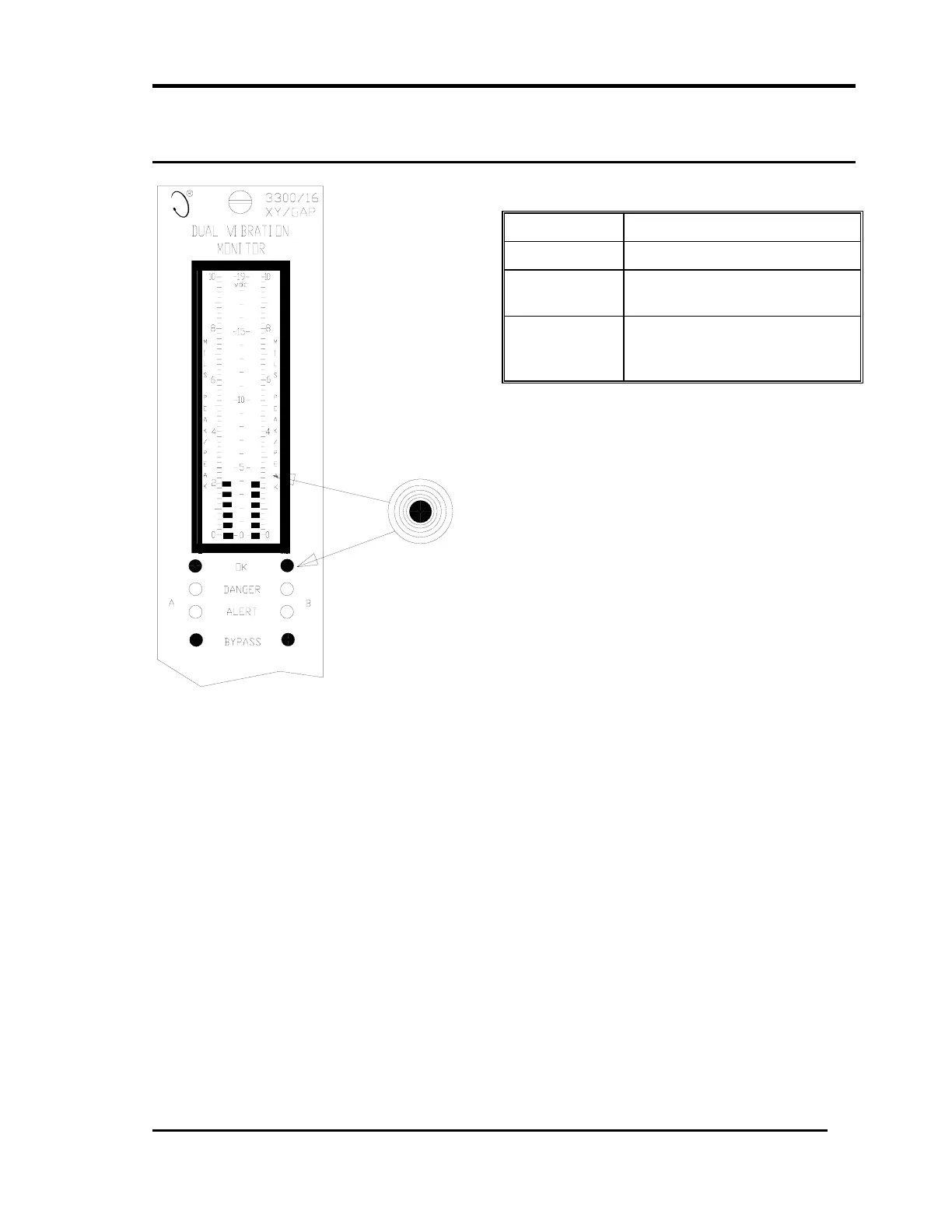

The monitor has three levels of self-test:

When the monitor detects an error, it

displays an error condition in one of two

ways depending on whether the error is

active or stored.

• An active error is an error that currently

exists.

• A stored error indicates that a storable

error has occurred since the last time

errors were cleared but this error is no

longer active.

If the monitor detects an active error, the following events occur:

• Monitoring stops until the problem is resolved

• The error code is stored in memory and flashes on the LCD bargraph

• The BYPASS LEDs come on

• The OK LEDs flash at 5 Hz

If the monitor no longer detects an active error and a stored error exists, the following

events occur:

• Monitoring resumes

• If the OK LED would otherwise be on, the OK LEDs flash at 5 Hz to indicate that an

error code has been stored.

SELF TEST PERFORMED

Power - up When the monitor is turned on.

Cyclic Continuous during monitoring

operations.

User-invoked When you initiate the self-test by

temporarily shorting the self-test

pins.

Loading...

Loading...