6.5 CONDENSATE SOAKAWAY

To keep external pipework to a minimum, locate the soakaway

as close as possible to the boiler but ensure it is at least 500 mm

from building foundations and away from other services, e.g. gas,

electricity, etc.

The condensate pipe may be run above or below ground level

and can enter either the top or side of the soakaway tube. Refer

to Figure 6-1.

Ensure that the drainage holes in the soakaway tube face away

from the building.

Backll both the soakaway tube, and the hole around it, with 10

mm limestone chippings.

Only use a soakaway where the soil is porous and drains easily.

Do not use in clay soils or where the soil is poorly drained.

! CAUTION !

Any damage due to condensate backing up into the boiler

due to a high water table, in the case of a soakaway, or

ooded drains when the condensate disposal is via a

gulley or soil stack, is not covered by the Grant product

guarantee.

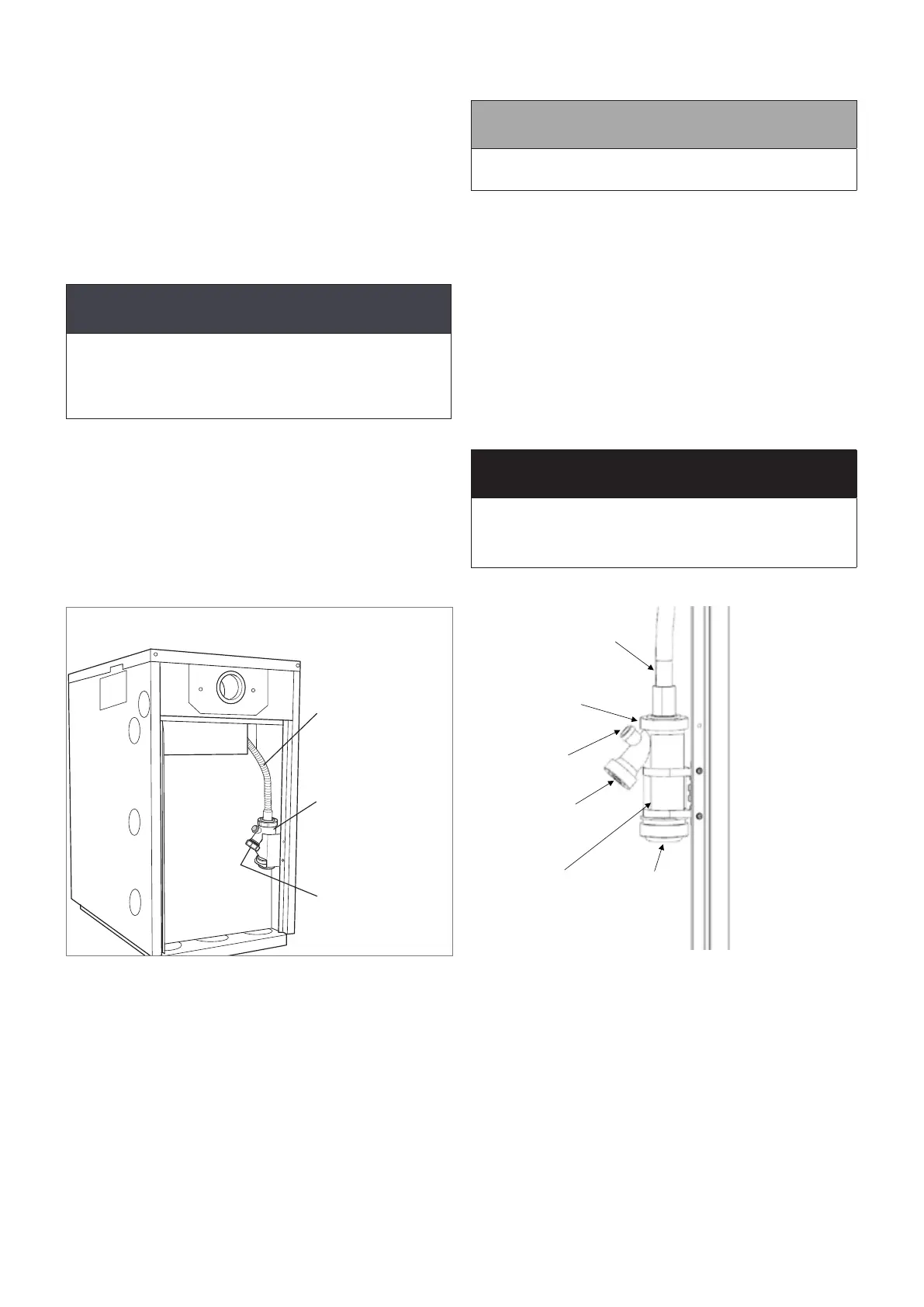

6.6 CONDENSATE TRAP

Grant Vortex boilers are supplied with a condensate trap to

provide the required 75 mm water seal in the condensate

discharge pipe from the boiler.

The condensate trap is factory tted inside the boiler casing -

mounted on the inside of the left hand side panel at the rear of the

boiler - in an accessible position to allow for routine maintenance,

see Figure 6-2.

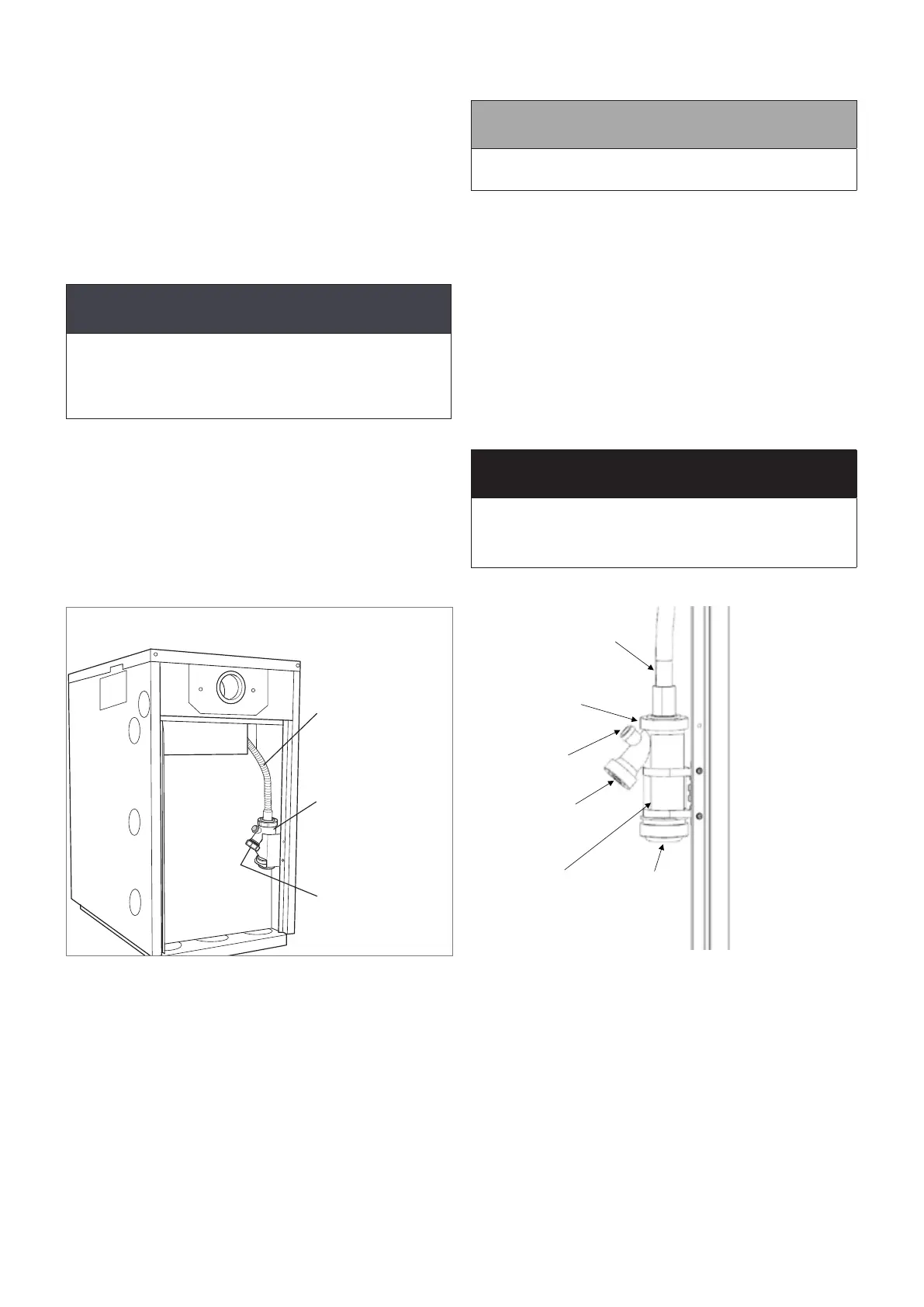

This trap incorporates a oat (which will create a seal when the

trap is empty) and an overow warning outlet (tted with a plastic

sealing cap), see Figure 6-3.

! NOTE !

Access must be available to allow for routine maintenance.

A exible hose connects the outlet of the condensing heat

exchanger to the trap inlet. Ensure the elbow connector on the

hose is fully pushed onto the ‘top hat’ inlet connector of the trap.

With the trap tted inside the boiler casing, the sealing cap must

be tted. If the trap is re-located outside the boiler, then the

following applies:

• If connecting the condensate discharge - either internally or

externally - into a waste system or soil stack - the sealing cap

must be tted in the trap outlet.

• On external discharge systems to a hopper, gully or

soakaway, the sealing cap should be removed from the trap

outlet.

• If there is any discharge of condensate from the overow

outlet, this could indicate a blockage (possibly due to

freezing). Turn o the boiler and investigate the cause. If

necessary contact your service engineer for assistance.

! WARNING !

Care should be taken when siting the trap such that the

overow outlet is readily visible and that any condensate

overowing from the outlet cannot cause either a hazard to

persons or damage to surrounding property or equipment.

Section 6: Condensate DisposalPage 18

Condensate

trap

Condensate

outlet to drain

Flexible hose

from outlet of

condensing

heat exchanger

Figure 6-2: Condensate trap loacation

drain pipe

trap

outlet to

warning

outlet

cap for

maintenance

Figure 6-3: Condensate trap details

Loading...

Loading...