Section 7: Sealed SystemsPage 20

7.1.2 PRESSURE GAUGE

The pressure gauge is factory tted in the boiler control panel. It

has an operating range of 0 to 4 bar. Refer to Section 1.4.

7.1.3 PRESSURE RELIEF (SAFETY) VALVE

The pressure relief (safety) valve is factory tted to the ow

pipework on the top of the boiler.

A discharge pipe should be connected to the outlet of the pressure

relief (safety) valve. This discharge pipe must terminate in a

position that will allow the discharge to be seen, but cannot cause

injury to persons or damage to property. Refer to Figure 5-1 for

the position of the PRV on all models.

7.1.4 FILLING LOOP

In order to ll or top up the heating system, a factory tted

lling loop is located at the front of the boiler, to the right of the

expansion vessel.

Refer to Section 7.2 for details on how to ll and vent the system.

7.1.5 HEATING SYSTEM

The maximum ‘setpoint’ temperature for the central heating water

is 75°C. Refer to Section 1.1.

An air vent should be tted in the ow and return pipes of the

highest point of the system.

If thermostatic radiator valves are tted to all radiators, a system

by-pass must be tted. The by-pass must be an automatic type.

All ttings used in the system must be able to withstand pressures

up to 3 bar. Radiator valves must comply with the requirements of

BS 2767.

One or more drain taps (to BS 2879) must be used to allow the

system to be completely drained.

7.1 SEALED SYSTEM

REQUIREMENTS

All Grant Vortex Pro Combi boilers must be used as part of a

sealed system complying with the requirements of BS EN 12828,

BS EN 12831 and BS EN 14336.

The maximum temperature of the central heating water is 75°C.

The boiler is supplied factory tted with the following items:

• 24 litre diaphragm expansion vessel complying with BS EN

13831

• Pressure gauge

• Pressure relief (safety) valve

• Approved lling loop

7.1.1 EXPANSION VESSEL

On all models the expansion vessel is factory tted on the front of

the boiler, inside the casing.

It is connected to the boiler via a exible hose to allow the vessel

to be removed from the boiler to access the front cleaning door

without disconnecting it. Take care to ensure that the exible hose

is not twisted or kinked.

Refer to Section 4.9 for further installation details.

! NOTE !

Ensure that the expansion vessel is of sucient size for

the system volume.

Refer to BS 7074-1 or the Domestic Heating Design Guide

to check the vessel size required.

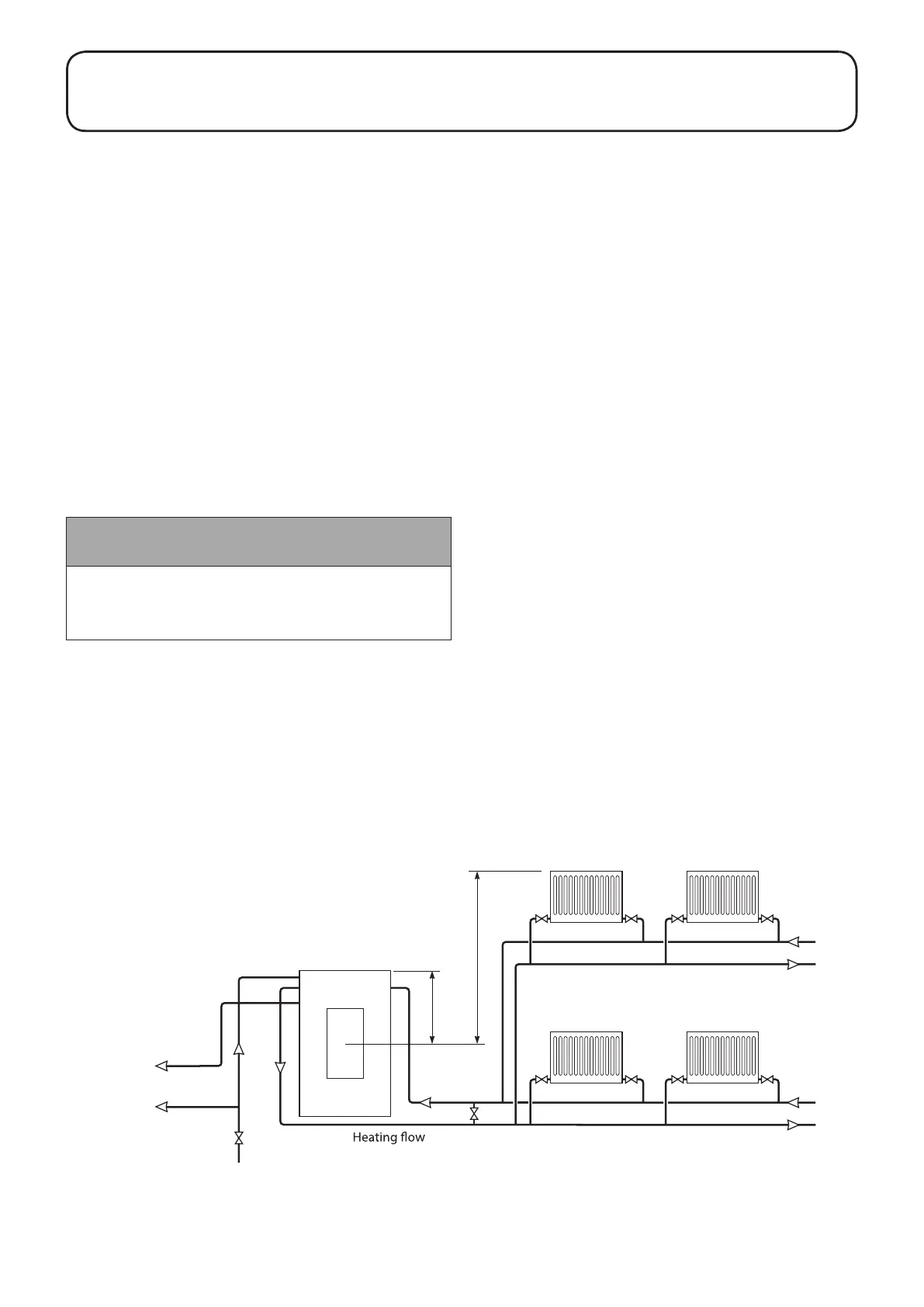

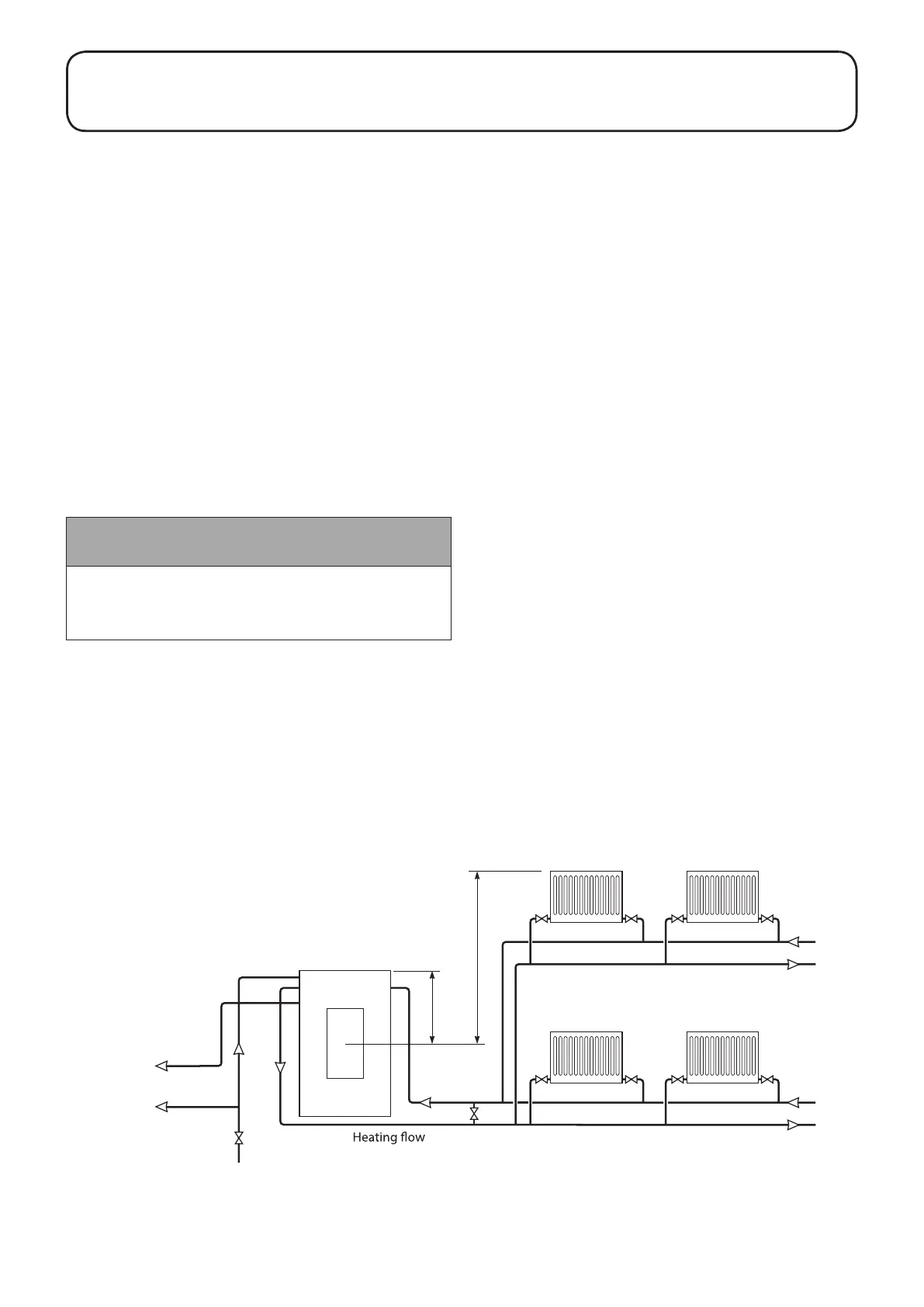

7 SEALED SYSTEMS

Figure 7-1: Sealed system

If thermostatic radiator valves

are fitted, the system must

incorporate an adequate by-pass.

Static head of system

350mm

Heating

return

By-pass if required

(automatic type)

Expansion

vessel

Boiler

Stop valve

Water mains

Domestic

cold water

Domestic

hot water

Loading...

Loading...