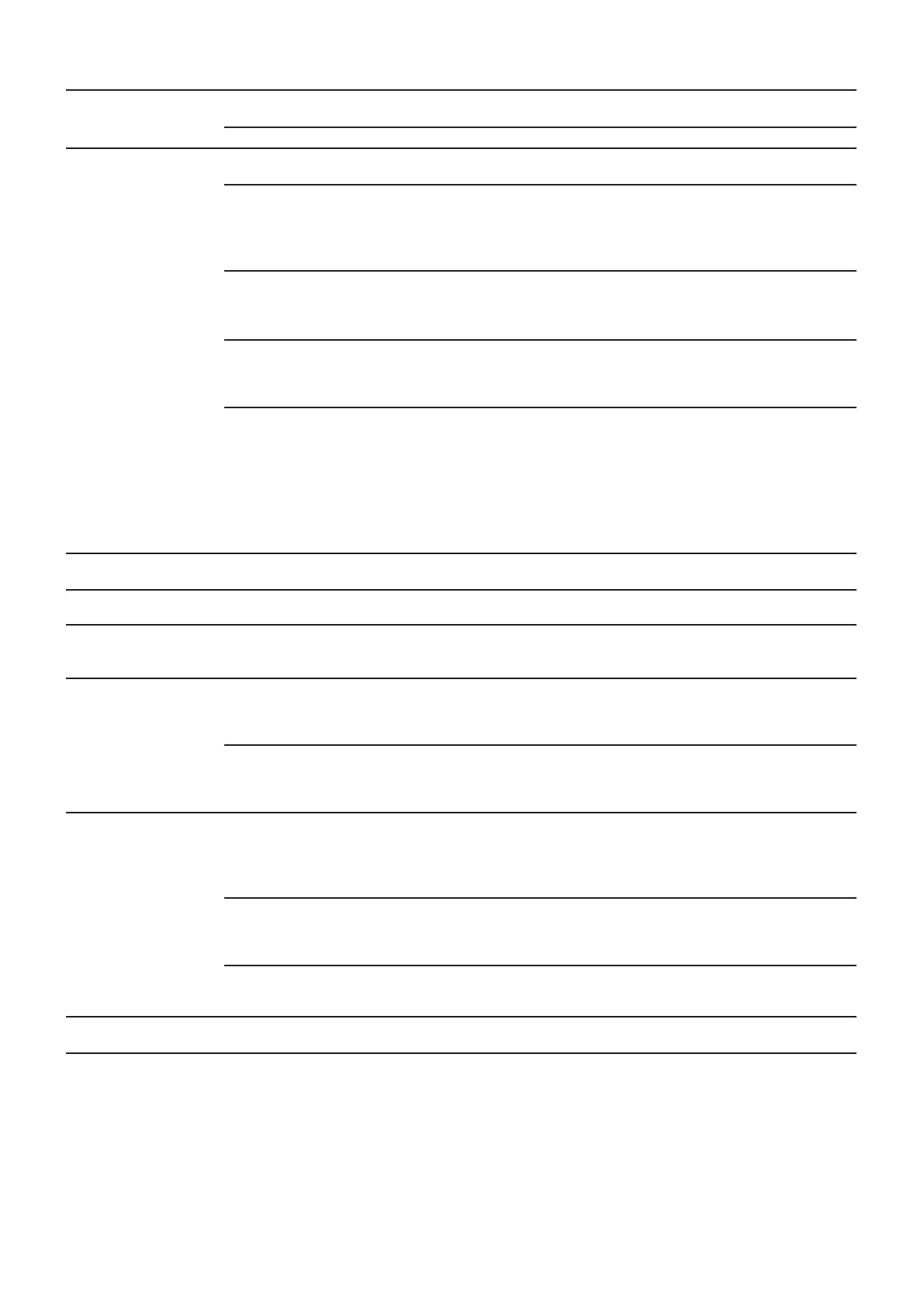

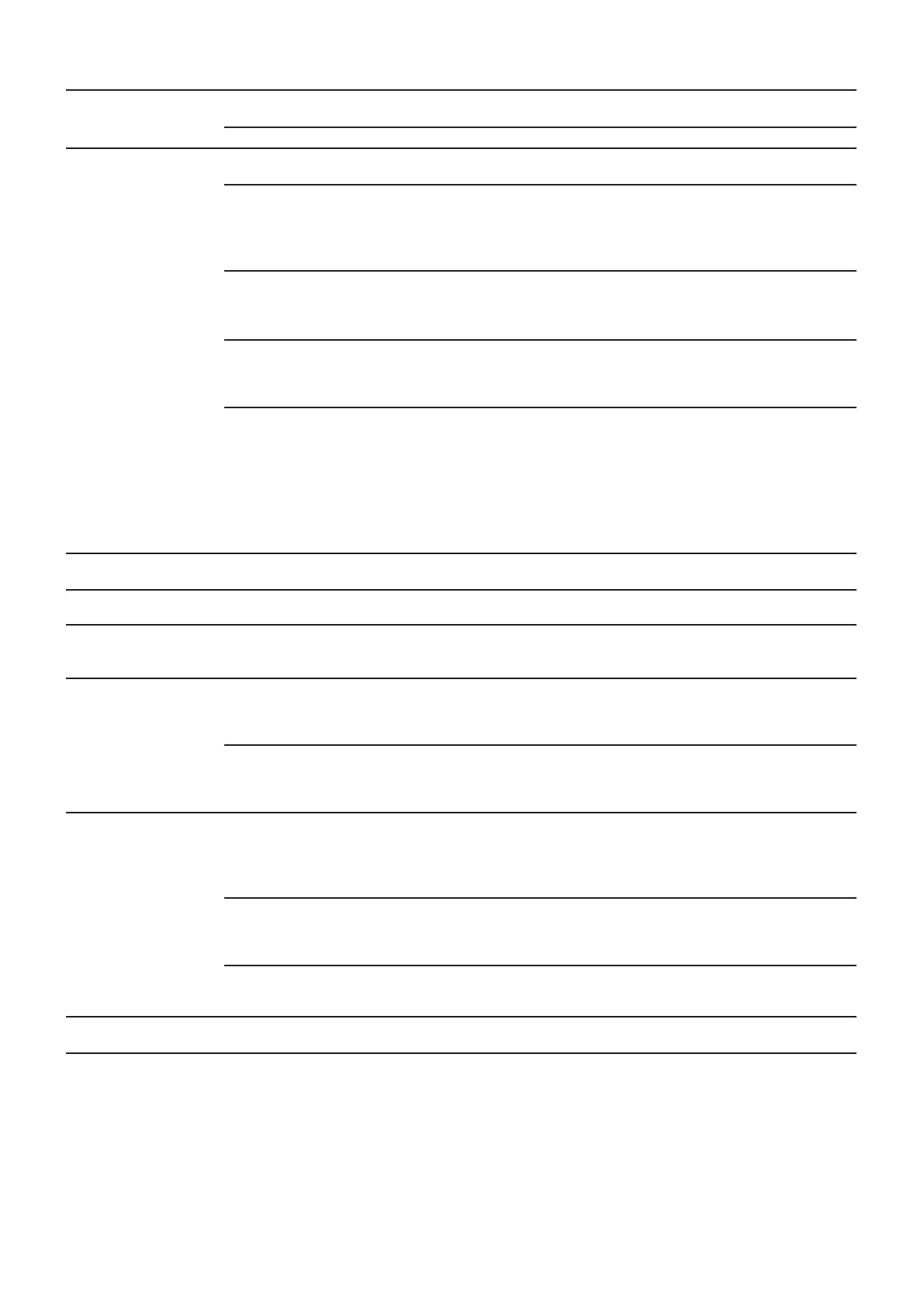

B NO HOT WATER - BUT CENTRAL HEATING OK

First, set the heating switch to OFF

Is the ‘DEMAND’ indicator

lit?

NO

Check programmer is calling for hot water.

If no programmer is tted: check ‘hot water’ switch is set to ‘CONSTANT’.

NO Check ‘heating’ switch is set to ‘TIMED’.

Is the ‘FLOW SWITCH’

indicator lit?

NO

Check hot water tap is open.

Check water ow rate is at least 3 litres/minute.

Cannot achieve 3 litres/

minute

Check the mains stop tap is open fully.

Check the cold water isolation valve in the boiler is open.

Check if the ow restrictor (located in the cold water isolation valve) is clear.

If not, clean restrictor or remove from valve.

NOTE: No ow restrictor is tted to the Combi 36 model.

Is the water pressure OK?

Low water pressure = low

water ow rate.

Check standing water pressure.

2 bar minimum standing pressure required.

Check running (dynamic) pressure.

1 bar minimum dynamic pressure required.

If water pressure is OK.

Check for blockage in plate heat exchanger unit.

NOTE: In hard water areas, scale will be produced that can block the plate heat

exchanger if no anti-scale protection has been installed.

Refer to Section 5 for further details.

Is plate heat exchanger is

OK.

Check ow switch is correctly positioned: the arrow (on ow switch body) must point in

the direction of ow, i.e. toward the front of boiler.

Check switch is free to operate: close cold water isolation valve, remove ow switch from

pipework - manually operate switch paddle to check.

Remove any debris/blockage from the pipework body or switch paddle.

Check for electrical continuity between ow switch terminals when switch is closed.

No continuity - replace ow switch.

No 230V - check connections at PCB.

If still no 230V - replace PCB.

Is the ‘FLOW SWITCH’

indicator lit?

YES

Flow switch is activated.

Continue to the next check.

Is the ‘DHW PUMP’

indicator lit?

NO Continue to next check.

Is the ‘DHW PUMP’

indicator ashing?

YES

Fast or slow ash

First, set boiler ‘ON/OFF’ switch to ‘OFF’.

Wait 5 seconds.

Then set ‘ON/OFF’ switch back to ‘ON’.

If the ‘DHW PUMP’ indicator

continues ashing.

Fast ash

(twice per second):

Indicates a possible fault

with the ‘store’ thermistor.

Check DHW ‘store’ thermistor connection to PCB.

Replace ‘store’ thermistor.

Slow ash

(once every 2 seconds):

Indicates a possible fault

with the PCB (relay).

Replace PCB.

Is the ‘DHW PUMP’

indicator lit?

YES

PCB is supplying voltage to

the DHW pump - but pump

is not working.

Check for electrical connections at the pump.

Check for 230V at the pump terminals.

Check if CH pump is stuck:

• Check for rotation of shaft/impeller.

• If still not operating, replace the DHW pump.

YES

DHW pump is working but

no circulation.

Check both pump valves are open.

Check non-return valve on DHW pump is operational (not sticking).

Check there are no air locks in the system (if removal of air is dicult - see additional

check list).

YES

DHW pumpis working and

water is circulating.

Hot or warm water should be present at hot tap.

If not: refer to ‘poor hot water’ procedure in Section 12.3.

Is the ‘BURNER’ indicator

lit?

YES

Is burner ring?

If no: refer to ‘burner not operating’ procedure in Section 12.2 (C).

Page 45Section 12: Fault Finding

Loading...

Loading...