HEIDENHAIN iTNC 530 119

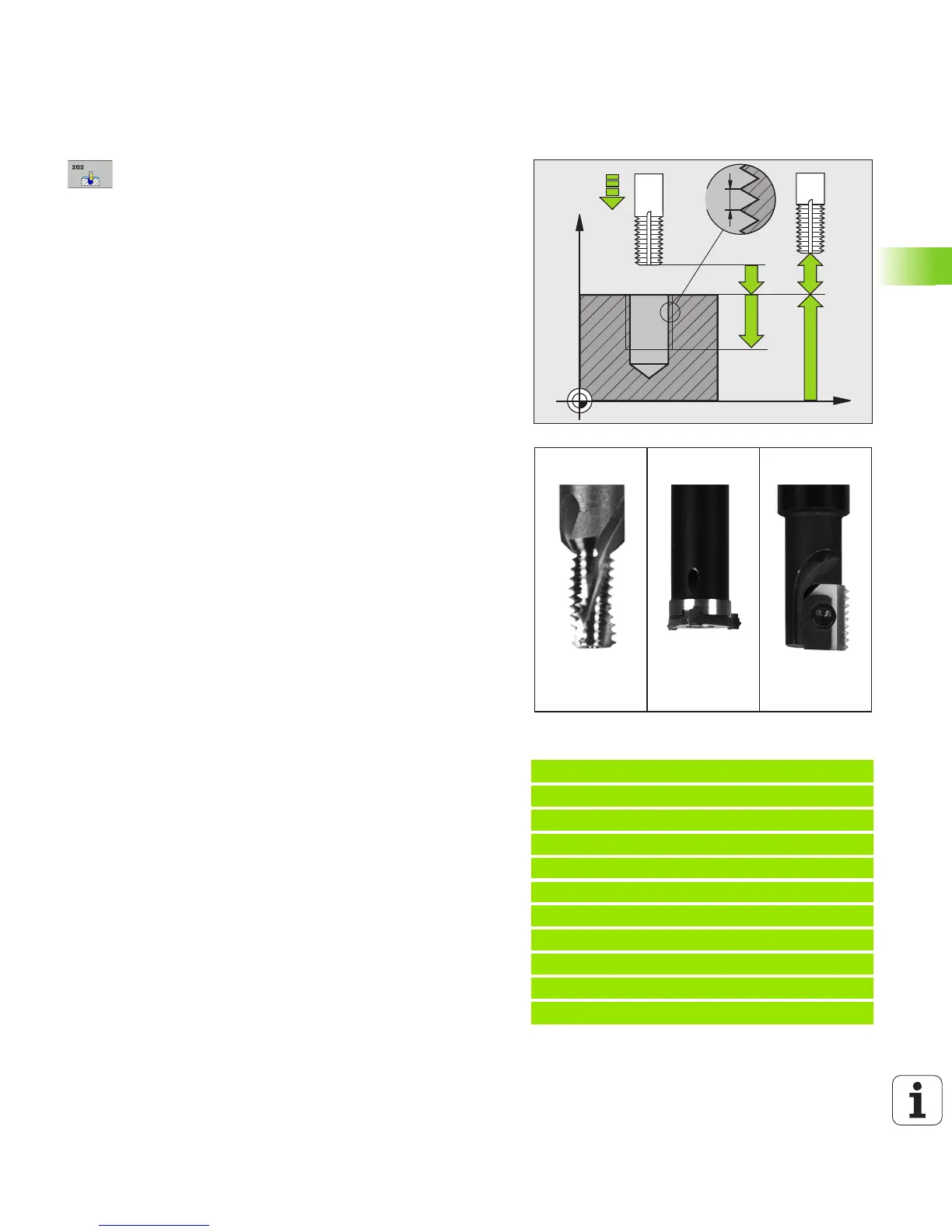

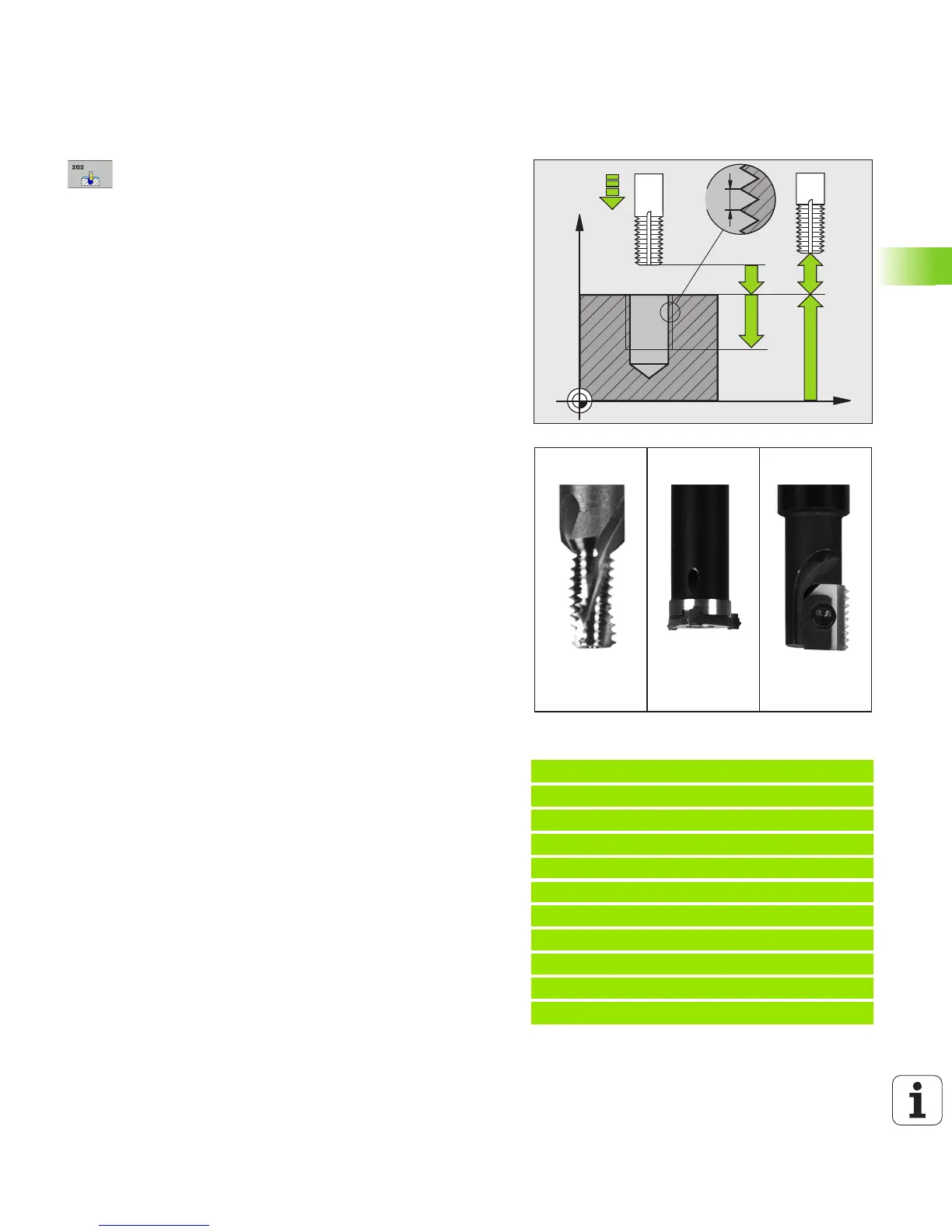

4.6 THREAD MILLING (Cycle 262, DIN/ISO: G262)

Cycle parameters

U Nominal diameter Q335: Nominal thread diameter.

Input range 0 to 99999.9999

U Thread pitch Q239: Pitch of the thread. The algebraic

sign differentiates between right-hand and left-hand

threads:

+= right-hand thread

– = left-hand thread

Input range -99.9999 to 99.9999

U Thread depth Q201 (incremental): Distance between

workpiece surface and root of thread. Input range -

99999.9999 to 99999.9999

U Threads per step Q355: Number of thread revolutions

by which the tool is moved:

0 = one 360° helical line to the thread depth

1 = continuous helical path over the entire length of

the thread

>1 = several helical paths with approach and

departure; between them, the TNC offsets the tool by

Q355, multiplied by the pitch. Input range 0 to 99999

U Feed rate for pre-positioning Q253: Traversing

speed of the tool in mm/min when plunging into the

workpiece, or when retracting from the workpiece.

Input range 0 to 99999.999 alternatively FMAX, FAUTO,

PREDEF.

U Climb or up-cut Q351: Type of milling operation with

M3

+1 = climb milling

–1 = up-cut milling

Alternatively PREDEF

U Setup clearance Q200 (incremental): Distance

between tool tip and workpiece surface. Input range

0 to 99999.9999, alternatively PREDEF

U Workpiece surface coordinate Q203 (absolute):

Coordinate of the workpiece surface. Input range:

-99999.9999 to 99999.9999

U 2nd setup clearance Q204 (incremental): Coordinate

in the spindle axis at which no collision between tool

and workpiece (fixtures) can occur. Input range 0 to

99999.9999, alternatively PREDEF

U Feed rate for milling Q207: Traversing speed of the

tool during milling in mm/min. Input range: 0 to

99999.999, alternatively FAUTO.

Example: NC blocks

25 CYCL DEF 262 THREAD MILLING

Q335=10 ;NOMINAL DIAMETER

Q239=+1.5 ;PITCH

Q201=-20 ;DEPTH OF THREAD

Q355=0 ;THREADS PER STEP

Q253=750 ;F PRE-POSITIONING

Q351=+1 ;CLIMB OR UP-CUT

Q200=2 ;SETUP CLEARANCE

Q203=+30 ;SURFACE COORDINATE

Q204=50 ;2ND SETUP CLEARANCE

Q207=500 ;FEED RATE FOR MILLING

Loading...

Loading...