76 Fixed Cycles: Drilling

3.3 DRILLING (Cycle 200)

Cycle parameters

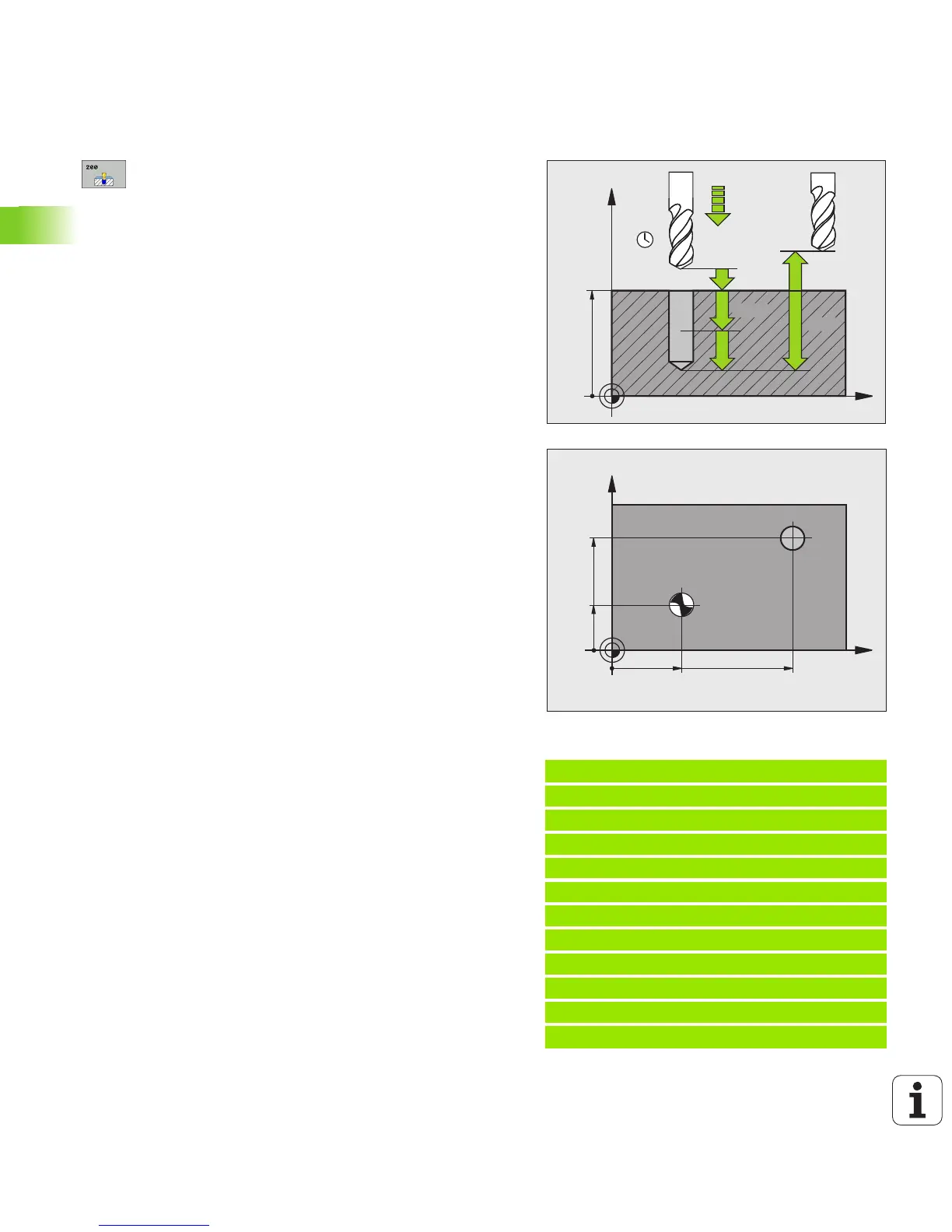

U Setup clearance Q200 (incremental): Distance

between tool tip and workpiece surface. Enter a

positive value. Input range 0 to 99999.9999,

alternatively PREDEF

U Depth Q201 (incremental): Distance between

workpiece surface and bottom of hole (tip of drill

taper). Input range –99999.9999 to 99999.9999

U Feed rate for plunging Q206: Traversing speed of

the tool during drilling in mm/min. Input range: 0 to

99999.999; alternatively FAUTO, FU.

U Plunging depth Q202 (incremental): Infeed per cut.

Input range 0 to 99999.9999. The depth does not

have to be a multiple of the plunging depth. The TNC

will go to depth in one movement if:

The plunging depth is equal to the depth

The plunging depth is greater than the depth

U Dwell time at top Q210: Time in seconds that the

tool remains at setup clearance after having been

retracted from the hole for chip release. Input range 0

to 3600.0000, alternatively PREDEF

U Workpiece surface coordinate Q203 (absolute):

Coordinate of the workpiece surface. Input range:

-99999.9999 to 99999.9999

U 2nd setup clearance Q204 (incremental): Coordinate

in the spindle axis at which no collision between tool

and workpiece (fixtures) can occur. Input range 0 to

99999.9999, alternatively PREDEF

U Dwell time at depth Q211: Time in seconds that the

tool remains at the hole bottom. Input range 0 to

3600.0000, alternatively PREDEF

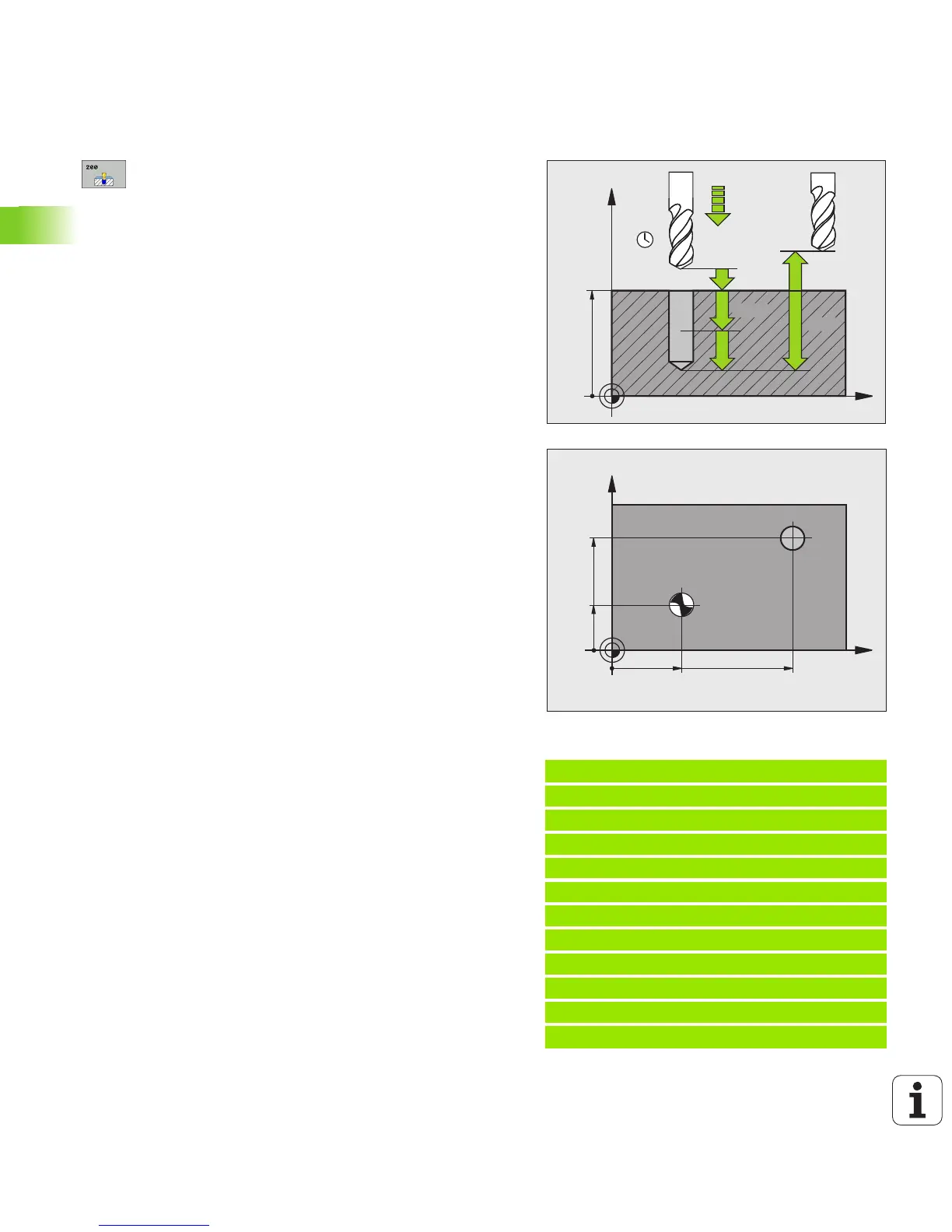

Example: NC blocks

11 CYCL DEF 200 DRILLING

Q200=2 ;SETUP CLEARANCE

Q201=-15 ;DEPTH

Q206=250 ;FEED RATE FOR PLNGNG

Q202=5 ;PLUNGING DEPTH

Q210=0 ;DWELL TIME AT TOP

Q203=+20 ;SURFACE COORDINATE

Q204=100 ;2ND SETUP CLEARANCE

Q211=0.1 ;DWELL TIME AT DEPTH

12 L X+30 Y+20 FMAX M3

13 CYCL CALL

14 L X+80 Y+50 FMAX M99

Loading...

Loading...