482 Touch Probe Cycles: Automatic Kinematics Measurement

18.5 PRESET COMPENSATION (Cycle 452, DIN/ISO: G452, Option)

18.5 PRESET COMPENSATION

(Cycle 452, DIN/ISO: G452,

Option)

Cycle run

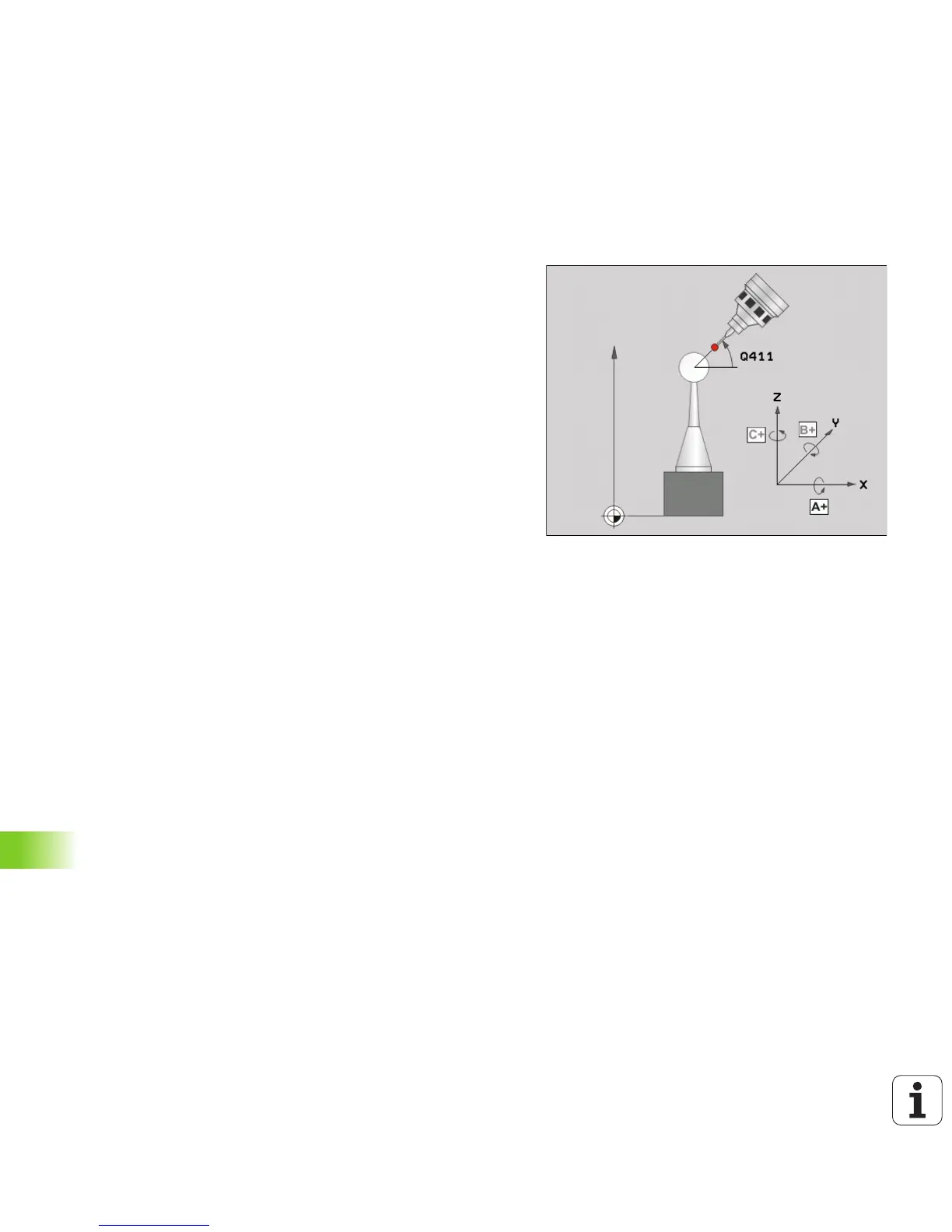

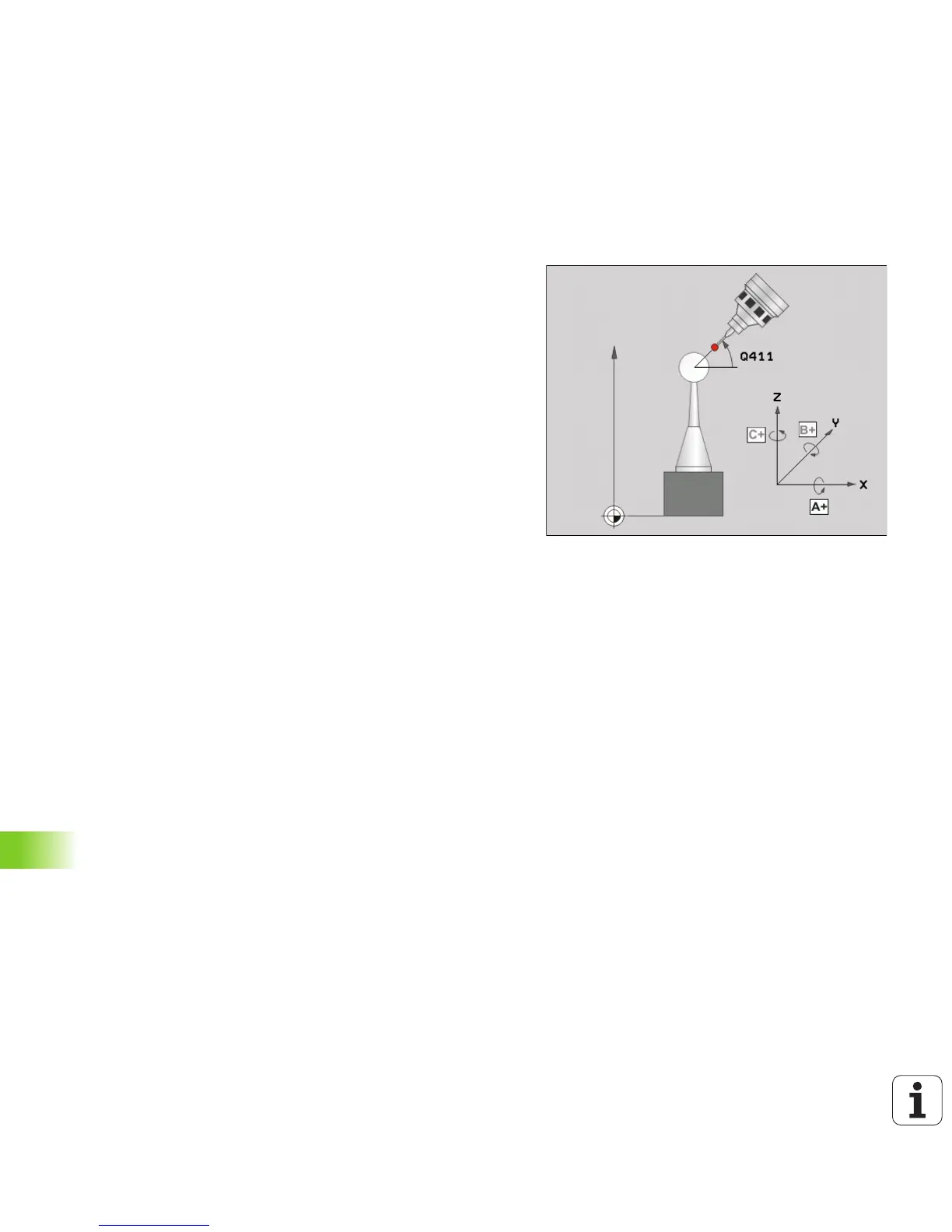

Touch probe cycle 452 optimizes the kinematic transformation chain

of your machine (see “MEASURE KINEMATICS (Cycle 451, DIN/ISO:

G451; Option)” on page 466). Then the TNC corrects the workpiece

coordinate system in the kinematics model in such a way that the

current preset is in the center of the calibration sphere after

optimization.

This cycle enables you, for example, to adjust different tool changer

heads so that the workpiece preset applies for all heads.

1 Clamp the calibration sphere

2 Measure the complete reference head with Cycle 451, and use

Cycle 451 to finally set the preset in the center of the sphere.

3 Insert the second head

4 Use Cycle 452 to measure the tool changer head up to the point

where the head is changed

5 Use Cycle 452 to adjust other tool changer heads to the reference

head.

Loading...

Loading...