322 Touch Probe Cycles: Automatic Measurement of Workpiece Misalignment

14.2 BASIC ROTATION (Cycle 400, DIN/ISO: G400)

14.2 BASIC ROTATION (Cycle 400,

DIN/ISO: G400)

Cycle run

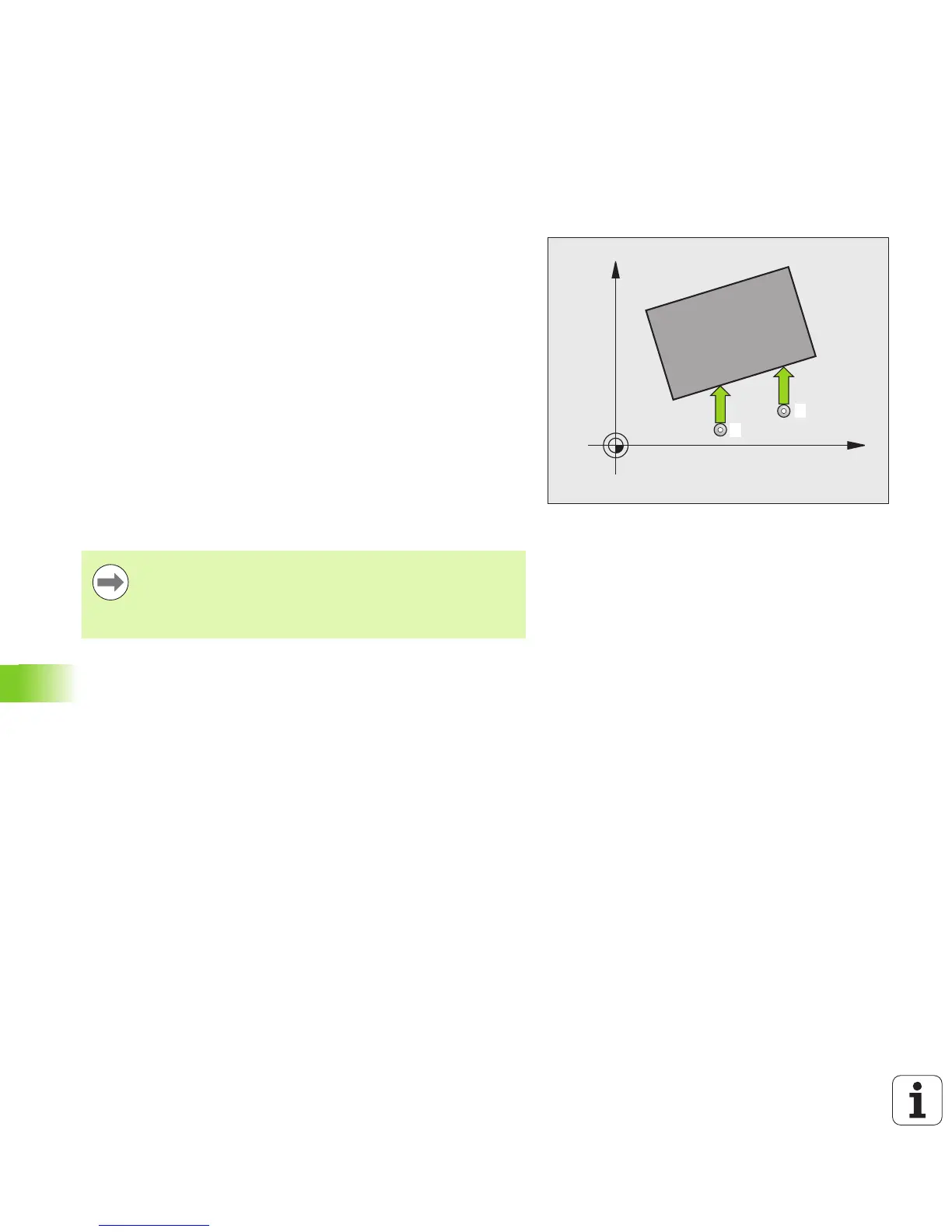

Touch probe cycle 400 determines a workpiece misalignment by

measuring two points, which must lie on a straight surface. With the

basic rotation function the TNC compensates the measured value.

1 Following the positioning logic (see “Executing touch probe

cycles” on page 318), the TNC positions the touch probe to the

programmed probe starting point 1 at rapid traverse (value from

MP6150). The TNC offsets the touch probe by the safety clearance

in the direction opposite the defined traverse direction.

2 Then the touch probe moves to the entered measuring height and

probes the first touch point at the probing feed rate (MP6120).

3 Then the touch probe moves to the next starting position 2 and

probes the second position.

4 The TNC returns the touch probe to the clearance height and

performs the basic rotation.

Please note while programming:

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

The TNC will reset an active basic rotation at the beginning

of the cycle.

Loading...

Loading...