165HEIDENHAIN TNC 426 B, TNC 430

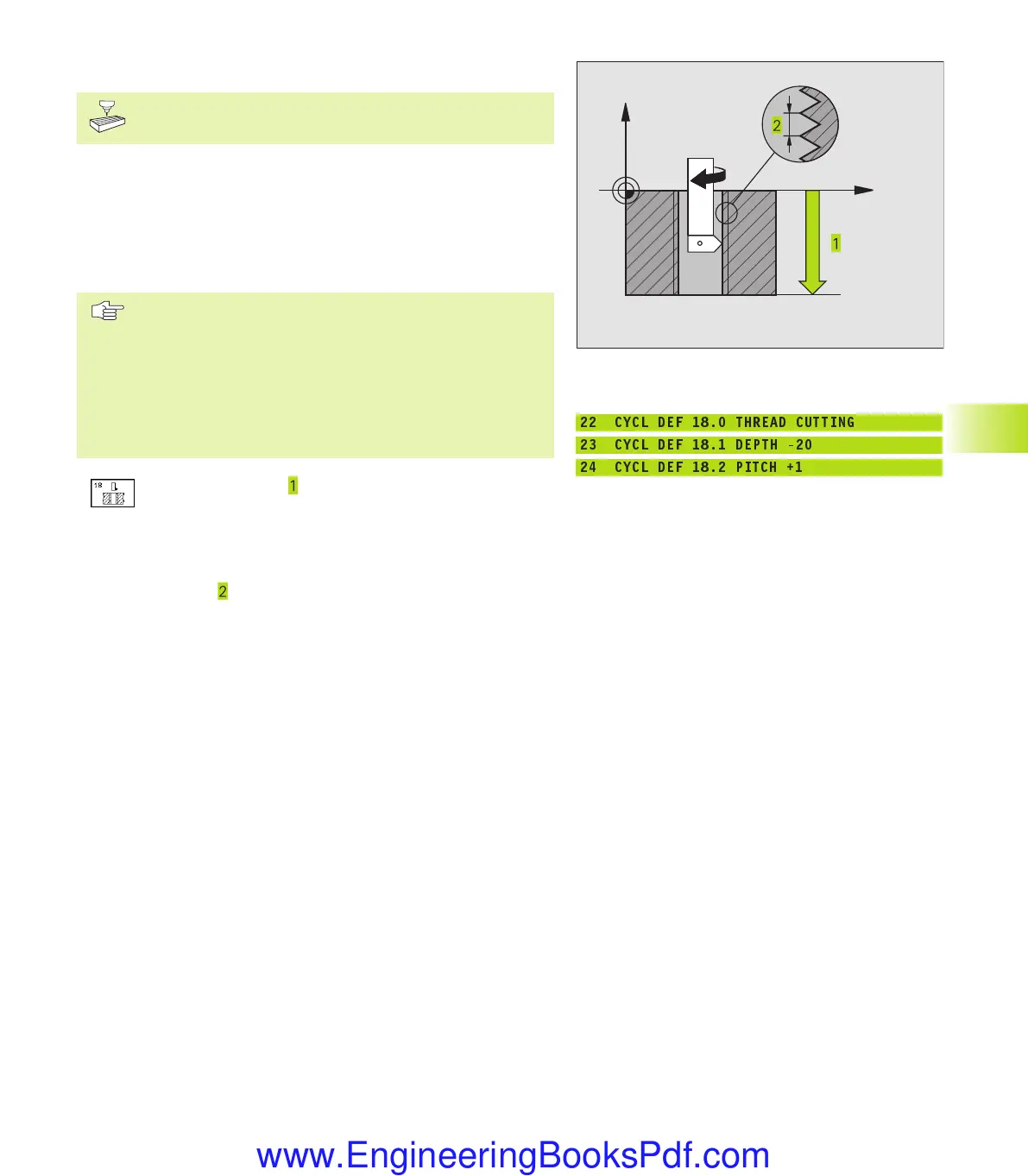

THREAD CUTTING (Cycle 18)

Machine and control must be specially prepared by the

machine tool builder to enable thread cutting.

Cycle 18 THREAD CUTTING is performed by means of spindle

control. The tool moves with the active spindle speed from its

current position to the entered depth. As soon as it reaches the end

of thread, spindle rotation is stopped. Tool approach and departure

must be programmed separately. The most convenient way to do

this is by using OEM cycles. The machine tool builder can give you

further information.

Before programming, note the following:

The TNC calculates the feed rate from the spindle speed.

If the spindle speed override is used during thread

cutting, the feed rate is automatically adjusted.

The feed-rate override knob is disabled.

The TNC automatically activates and deactivates spindle

rotation. Do not program M3 or M4 before cycle call.

ú

Total hole depth : Distance between current tool

position and end of thread.

The algebraic sign for the total hole depth determines

the working direction (a negative value means a

negative working direction in the tool axis)

ú

PITCH :

Pitch of the thread. The algebraic sign differentiates

between right-hand and left-hand threads:

+ = right-hand thread (M3 with negative depth)

– = left-hand thread (M4 with negative depth)

8.2 Drilling Cycles

X

Z

Example NC blocks:

22 CYCL DEF 18.0 THREAD CUTTING

23 CYCL DEF 18.1 DEPTH -20

24 CYCL DEF 18.2 PITCH +1

kkap8.pm6 30.06.2006, 07:03165

www.EngineeringBooksPdf.com

Loading...

Loading...