179HEIDENHAIN TNC 426 B, TNC 430

ú

Feed rate for plunging: Traversing speed of the tool

during penetration

ú

1st side length : Slot length; specify the sign to

determine the first milling direction

ú

2nd side length : Slot width

ú

Feed rate F: Traversing speed of the tool in the

working plane

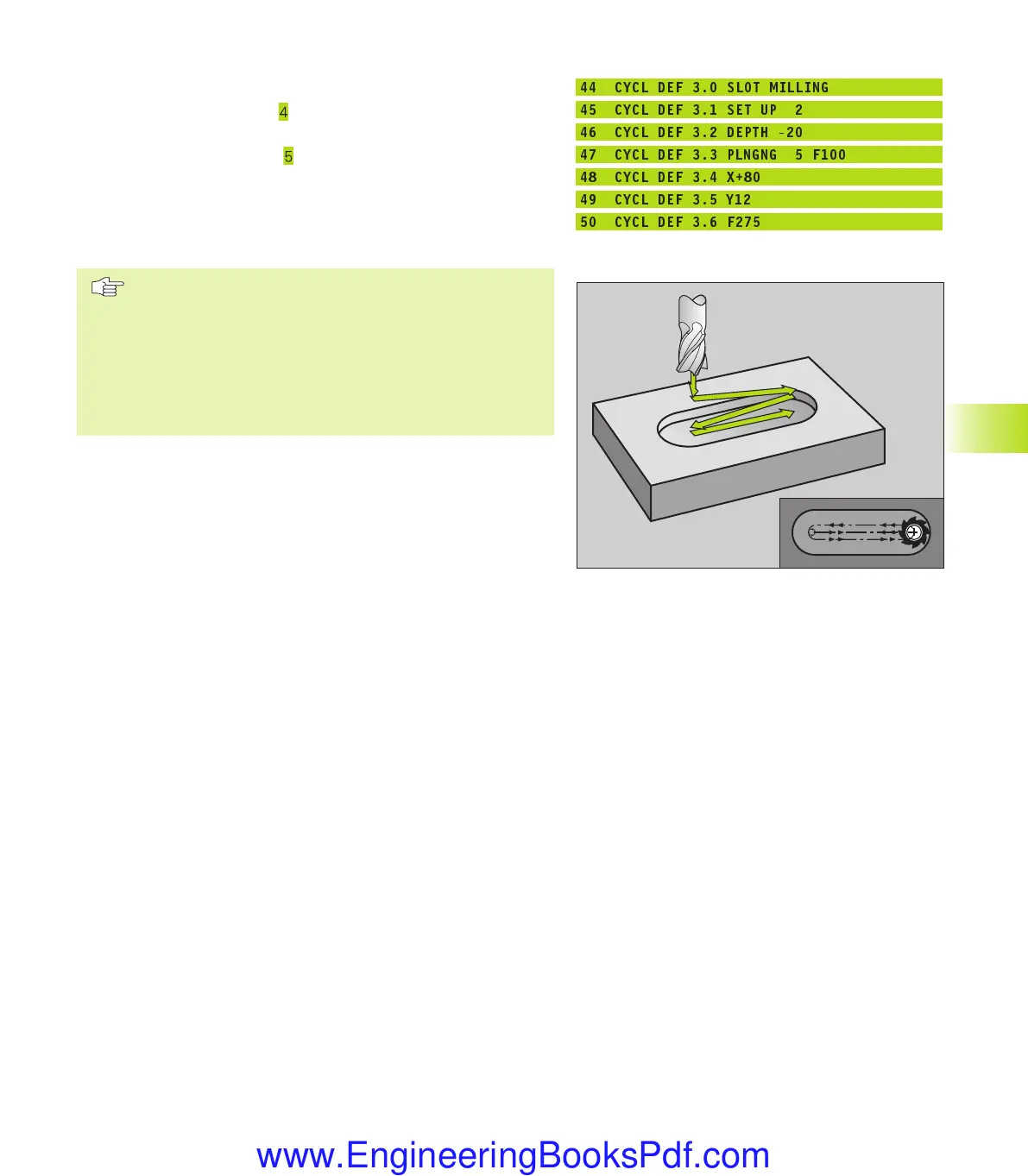

SLOT with reciprocating plunge-cut (Cycle 210)

Before programming, note the following:

The algebraic sign for the depth parameter determines

the working direction.

The cutter diameter must not be larger than the slot

width and not smaller than a third of the slot width.

The cutter diameter must be smaller than half the slot

length. The TNC otherwise cannot execute this cycle.

Roughing process

1 At rapid traverse, the TNC positions the tool in the tool axis to the

2nd set-up clearance and subsequently to the center of the left

circle. From there, the TNC positions the tool to set-up clearance

above the workpiece surface.

2 The tool moves at the feed rate for milling to the workpiece

surface. From there, the cutter advances in the longitudinal

direction of the slot — plunge-cutting obliquely into the material

— until it reaches the center of the right circle.

3 The tool then moves back to the center of the left circle, again

with oblique plunge-cutting. This process is repeated until the

programmed milling depth is reached.

4 At the milling depth, the TNC moves the tool for the purpose of

face milling to the other end of the slot and then back to the

center of the slot.

Finishing process

5 The TNC advances the tool from the slot center tangentially to

the contour of the finished part. The tool subsequently climb

mills the contour (with M3).

6 When the tool reaches the end of the contour, it departs the

contour tangentially and returns to the center of the slot.

7 At the end of the cycle, the tool is retracted in rapid traverse

FMAX to set-up clearance and — if programmed — to the 2nd

set-up clearance.

8.3 Cycle for Milling Pockets, Studs and Slots

Example NC blocks:

44 CYCL DEF 3.0 SLOT MILLING

45 CYCL DEF 3.1 SET UP 2

46 CYCL DEF 3.2 DEPTH -20

47 CYCL DEF 3.3 PLNGNG 5 F100

48 CYCL DEF 3.4 X+80

49 CYCL DEF 3.5 Y12

50 CYCL DEF 3.6 F275

kkap8.pm6 30.06.2006, 07:03179

www.EngineeringBooksPdf.com

Loading...

Loading...