eXtendo

®

Thermal Printer Family

HENGSTLER

Part No. D 684 124 Mod. No. 4 080812 LEV page 10 of 38

range. 58 mm and 60 mm paper widths are very common, and are considered standards.

Paper guides are not needed to handle these two paper widths.

The X-80 has a maximum paper width of 86 mm. While 86 mm wide paper may sometimes

be used, the most common larger paper widths are 80 mm and 82.5 mm (3¼ inches). These

do require a paper guide to use. This, then, is one of the most obvious differences between

the two printers. The X-56 does not come with paper guides, though they may be ordered

separately. The X-80 is always shipped with paper guides, since they are needed for the

most common paper widths.

Current consumption is also a difference between these two printers. Because of the greater

number of heating elements (dots) that can be fired simultaneously in the X-80 (the 203 dpi

version of the X-80 has 640, while the same resolution version of the X-56 has 448), the

current consumption can be higher by 43%. This does not mean the X-80 current is always

higher, however. Current consumption is controlled by many factors, most importantly by the

density of what is being printed. For example, if the same receipt is printed on an X-56 and

X-80, the current consumption will be approximately the same, since the same number of

dots is being fired on both printers.

Current consumption is also affected by whether the heating elements are fired as one block,

the burn time (the length of time that the dots are on), whether graphics are being printed,

whether sleep mode is employed to reduce current, and other factors.

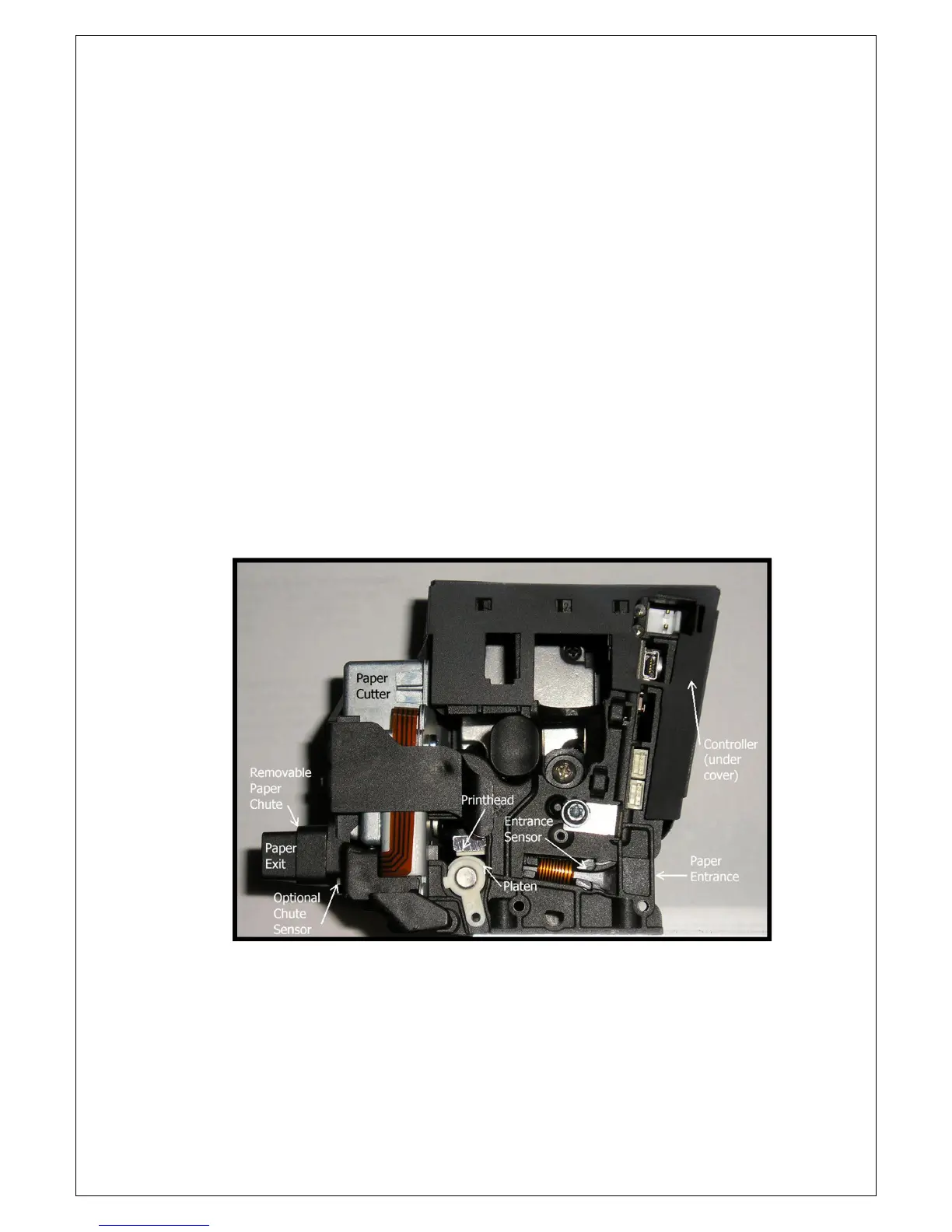

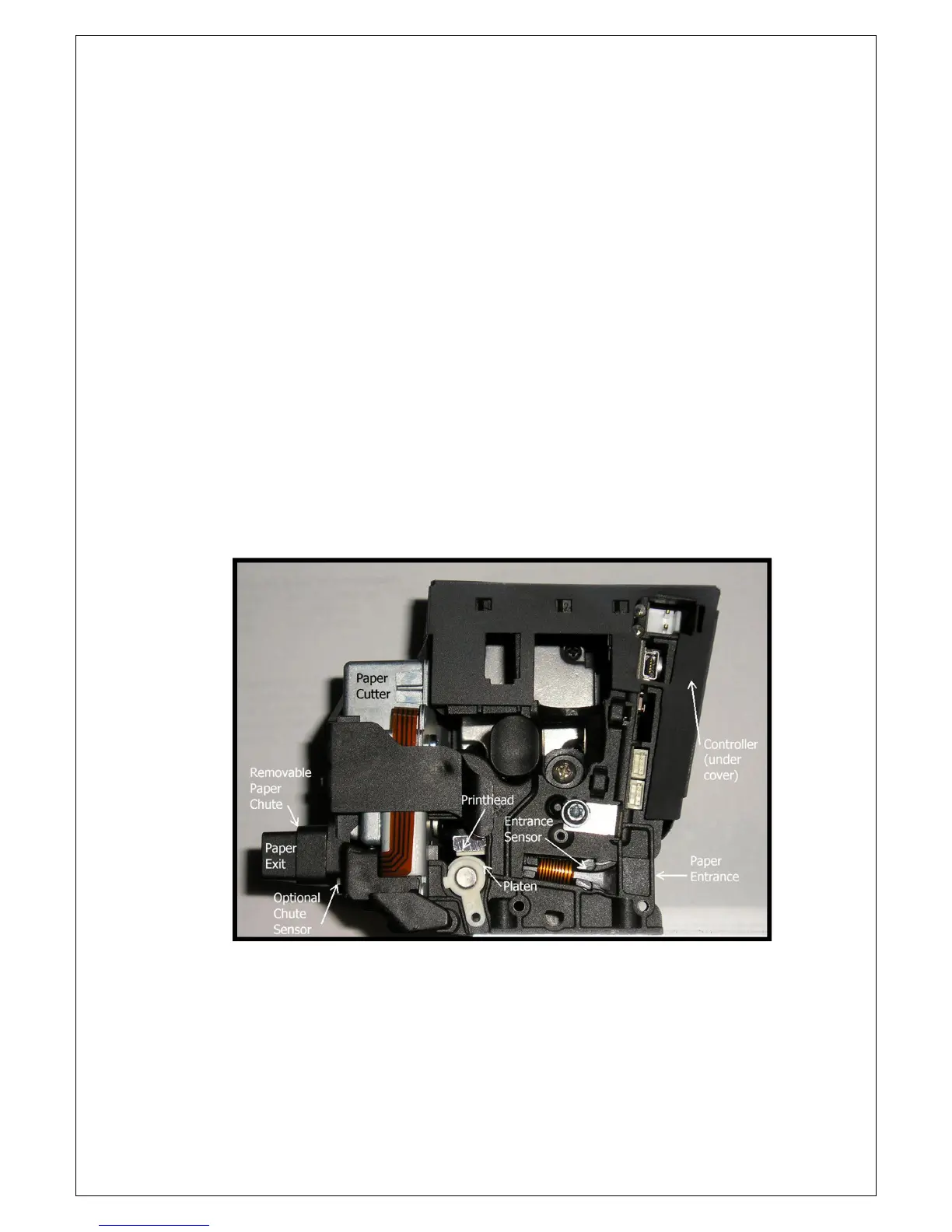

3.3. Functional View

Figure 1

3.4. Description of Components and Operation

There are several key components or modules to the eXtendo

®

family of thermal printers.

(Please refer to Fig. 1.) The thermal printhead is positioned above the platen. The platen

acts as a roller to advance the paper at the same time it acts as a surface against which the

spring-loaded printhead presses the paper to insure good thermal conductivity. The interface,

motor used to turn the platen (not visible in Fig. 1), sensors, printhead, and paper cutter are

all connected to the controller, which sends commands and causes these components to

Loading...

Loading...