8 REFRIGERANT PIPING & REFRIGERANT CHARGE

! CAUTION

Make sure that refrigerant piping installation complies with the legislation EN378 and local legislation.

8.1 PIPING MATERIALS

1

2

3

? NOTE

• A system with no moisture or oil contamination will give maximum

performance and lifecycle compared to that of a poorly prepared

system. Take particular care to ensure all copper piping is clean and

dry internally.

• There is no refrigerant in the cycle of the indoor unit.

! CAUTION

• All external piping shall be selected in size and dimension avoiding

any mechanical strength due to contraction or expansion, vibration or

refrigerant pulsation.

• All the piping shall be protected against any environmental effect like

water freezing, corrosion, etc. When exible pipe is used, precautions

shall be taken against mechanical damages, excessive stresses by

torsion or any other.

• Flare nut connections shall be accessible for maintenance purposes.

• Ensure that refrigerant piping is earthed prior to units interconnection

and in case of additional refrigerant charging is required.

• Cap the end of the pipe when pipe is to be inserted through a hole.

• Do not put pipes on the ground directly without a cap or vinyl tape at

the end of the pipe.

• If piping installation is not completed until next day or over a longer

period of time, braze off the ends of the piping and charge with

oxygen free nitrogen through a Schrader valve type access tting to

prevent moisture and particle contamination.

• Do not use insulation material that contains NH3 because it can

damage cooper pipe material and can be a source of future leakage.

! CAUTION

• Do not use insulation material that contains NH3 because it can

damage cooper pipe material and can be a source of future leakage.

• Completely insulate both refrigerant gas piping and liquid piping

between the indoor unit(s) and the outdoor unit.

• If not insulated, dew will occur on the piping surface.

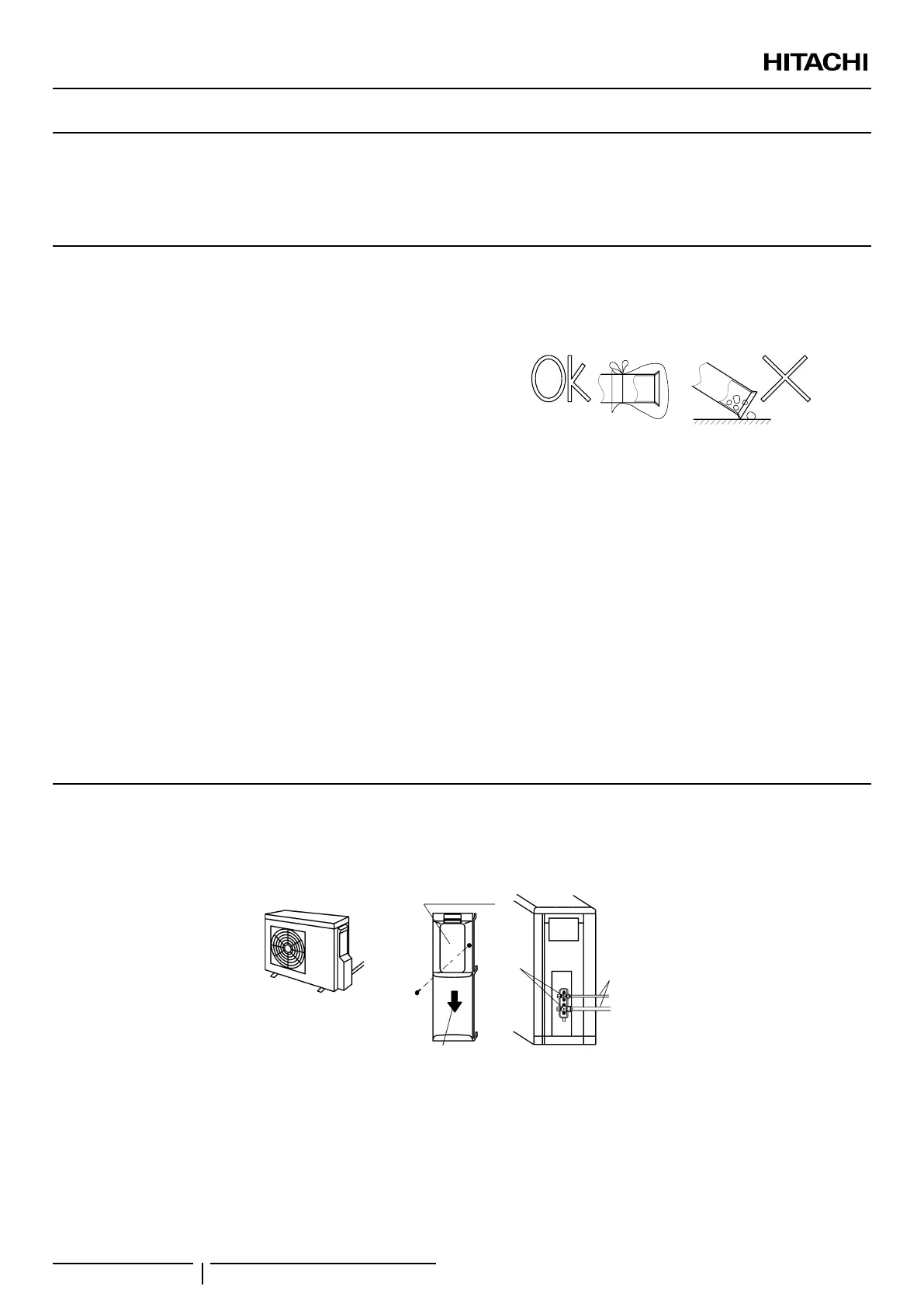

8.2 PIPING CONNECTION FOR OUTDOOR UNIT

1

2

3

4

5

6

PMML0509 rev.0 - 02/2019

8

Loading...

Loading...