OPERATING INSTRUCTIONS

10

V-10 TOUCH SCREEN BOILER CONTROLLER

Burner On From – This feature is found on a load set to External Control. The

setting can be Therm. or Ext. Control so that the load will respond to a call for

heat from either the Thermostat or External Control. If set as Therm. then the

boiler will wait for a call for heat on the Thermostat terminal associated with the

load and then look at the Ext. Cont. terminals for the target water temperature

signal. If set to Ext.Cont., the controller only uses the Ext. Cont. terminals to

determine a call for heat. If the voltage at the Ext. Cont. terminals is below

2.1VDC there is no call for heat. If the voltage is at or above 2.1VDC, then there

is a call for heat.

Fail Safe Enable – Fail Safe Enable is only available in External Control and only

if the Burner On From is set to External Control. If this feature is active and the

External Control voltage drops below 0.25Vdc, the boiler will automatically turn

on the Boiler Pump (if selected “ON”), the load pump, and operate the boiler to

the Fail Safe Set Point temperature. This temperature set point is adjustable.

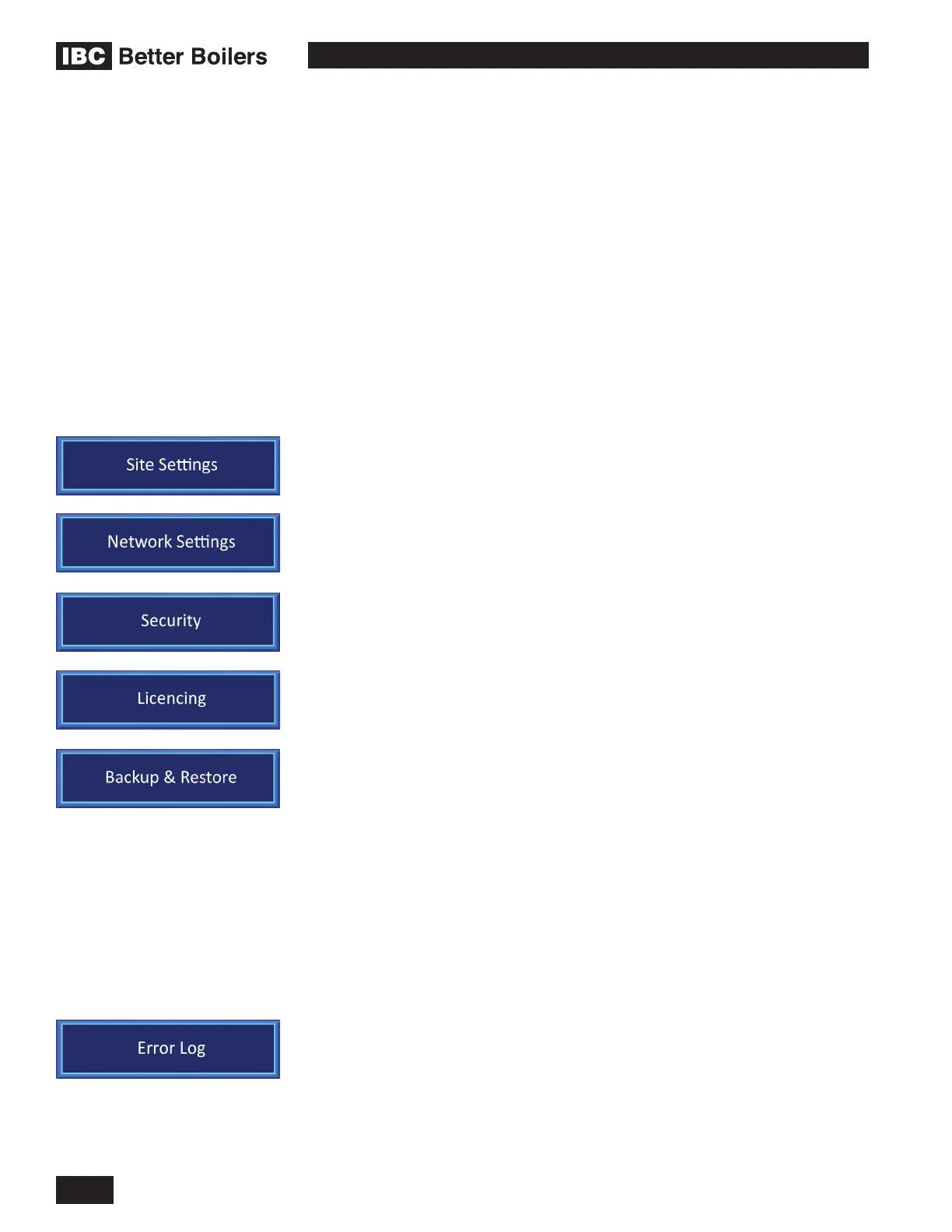

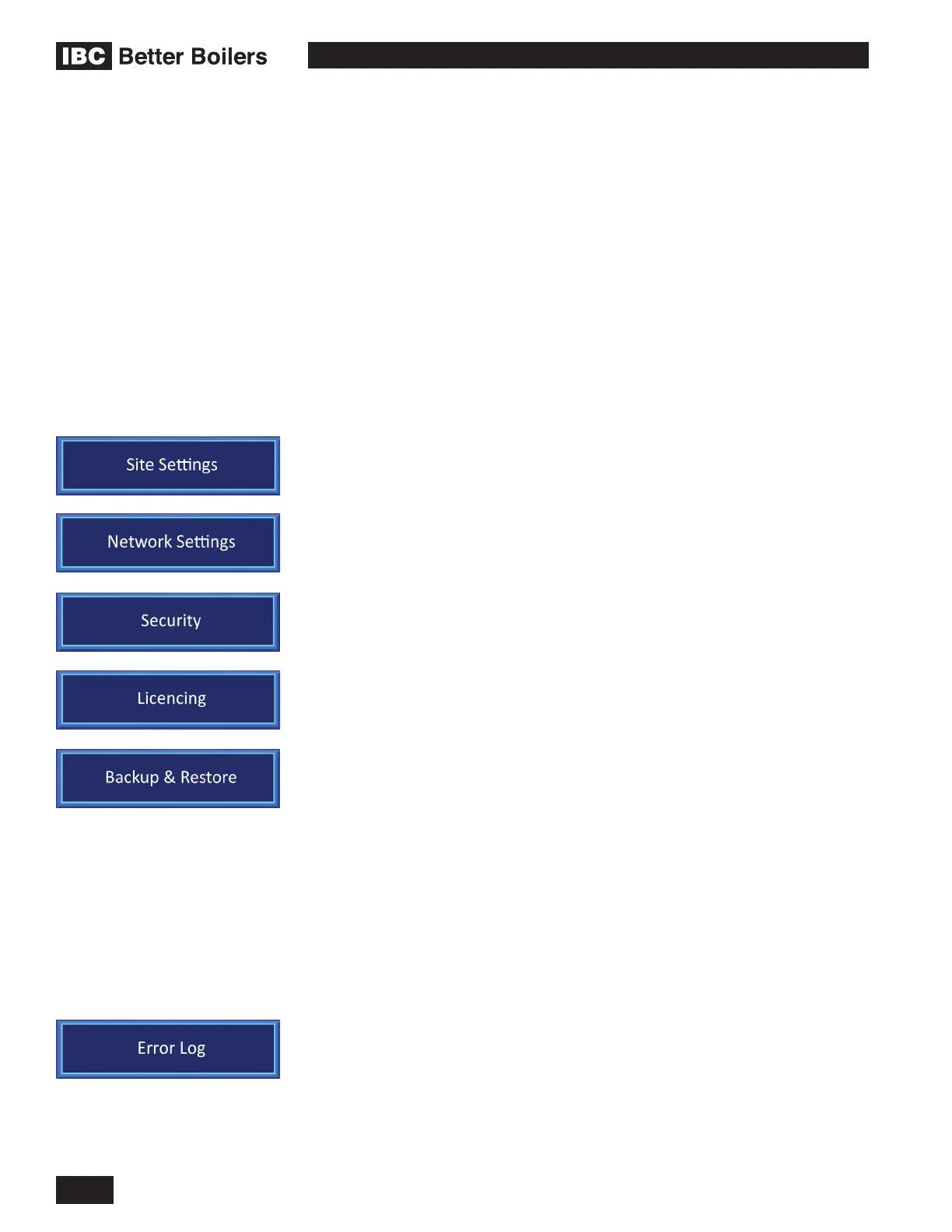

1.5.5.2 SYSTEM SETTINGS

Site Settings gives the installer access to boiler operating parameters that are

not specic to any load. Included are the load control type, primary pump purge

time, manual pump purge, and the variable speed output control settings.

The Network Settings screen is used to assign the boiler its ID, address and

network conguration to support multi-boiler operation and connection to internet

data networks.

The Security control setting allows the Security mode to be set On or Off. When

On is selected the User Password and Installer Password are displayed until

OK or Back are pressed.

Licensing is used to activate special add-on software packages.

Backup & Restore is used to backup or restore the boiler’s complete controller

conguration and settings to/from a USB memory stick or SD-Card inserted into

the controller. The Backup/Restore Type can be This Boiler or Boiler Model.

“This Boiler” creates or loads a copy of the conguration for the specic single

boiler. “Boiler Model” creates or loads a copy/clone of the conguration. This

feature facilitates the creation of a standard boiler conguration that can quickly

be loaded into another boiler of the same model.

1.5.6 - Diagnostics

The Diagnostics menu is a valuable tool for the installer and service provider.

Access to the following Diagnostics tools is available;

Each time an error condition happens a record for the error(s) is created

and stored in the controller memory. An error record includes the date, time,

classication, type(s) and the state of key boiler operating parameters at the time

the error event occurred. The controller can store a practically unlimited number

of error records.

Loading...

Loading...